DCOM Volume I Appendix G

Appendix G:ADDITIONAL DETAILS OF VARIOUS UNIT OPERATIONS

1. Horizontal-Flow Roughing Filters (HRF)

Features of HRF

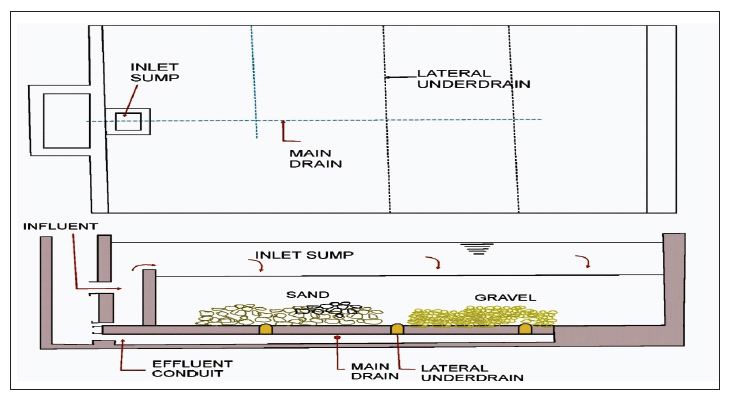

The filter box comprises of 2 to 4 compartments filled with gravel media of

different sizes, coarsest in the first compartment where the bulk of solids will be

retained, to finest in the last compartment which acts as polisher, removing the

last traces of solids;

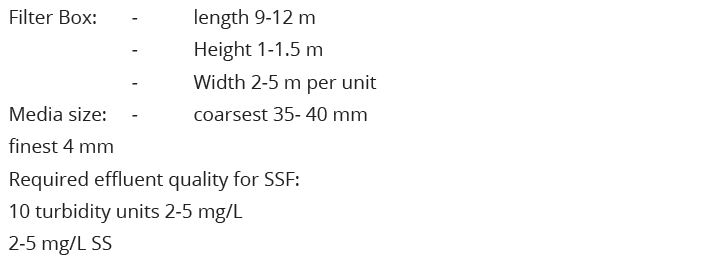

The raw water enters via an inlet channel across the filter width and falls over a weir into an inlet chamber which allows for settlement of coarse solids and separation of floating material.

Water passes into the first and subsequent filter compartments through openings in the separation walls. Treated water is collected in an outlet chamber and discharged over a weir- (for flow measurement) to an outlet channel and then to the SSF

The length of the filter box depends on raw water quality, hydraulic loading and media size.

Height should be limited to about 1.5m to allow for easy removal of media for manual cleaning.

The width depends on the required filter capacity. A minimum of 2 HRF units are provided, to allow for one being out of service for cleaning, and an adjacent area for gravel cleaning should be provided.

Design Considerations for HRF

(i) Characteristics of the raw water quality in both dry and rainy seasons i.e.;

Turbidity;Suspended solids or filterability; and E-coli

(ii) Raw water intake site location, elevation, high/low flows and water levels;

(iii) Treatment plant site, elevation, foundation conditions;

(iv) Hours of operation of intake, HRF, SSF and distribution;

(v) Availability of raw materials, gravel, sand, rock; and

(vi) Requirements for pre-sedimentation with or without combined raw water

balancing tank.

Design Criteria of HRF

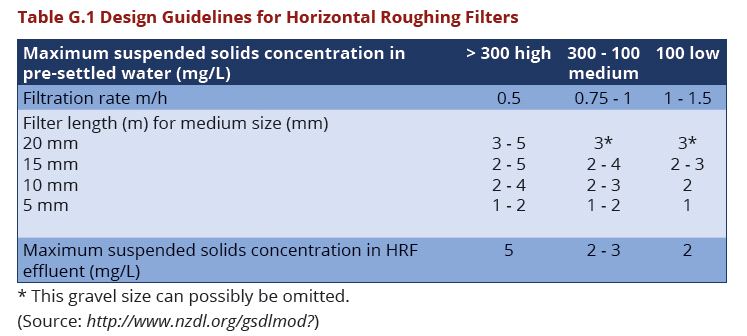

The criteria for design of HRF are as follows (also illustrated in Table G.1)

Filtration rate (m/s) ranges between 0.3 and 1.5 m/h. It is defined here as hydraulic

load (m³/h) per unit of vertical cross section area (m²) of the filter;

Openings in compartment walls; 10-20% of cross- sectional area, evenly distributed

Other criteria, such as expected efficiency of Suspended Solids (SS) removal, length of filter runs, required maximum head loss, etc., may be estimated by means of a monograph if necessary.

The outlet weir level should be 30-40 cm below the top level of filter material in order to allow for head loss across the filter, which builds up as the length of filter run increases and the filter loads up with silt.

Filter material ranges between 20 and 4 mm in size, and is usually distributed as coarse, medium and fine fraction in three subsequent filter compartments.

Filter length is dependent on raw water turbidity and usually lies within 5 to 7 m. Due to the comparatively long filter length.

Horizontal-flow roughing filters can handle short turbidity peaks of 500 to 1,000 NTU.

The filter has a series of differently graded filter material separated by perforated walls, to the filter outlet where the raw water runs in horizontal direction from the inlet compartment. These are: gravel; broken stones/rocks; burnt bricks; burnt charcoal; (prior testing at pilot and coconut fibre (plant level is necessary).

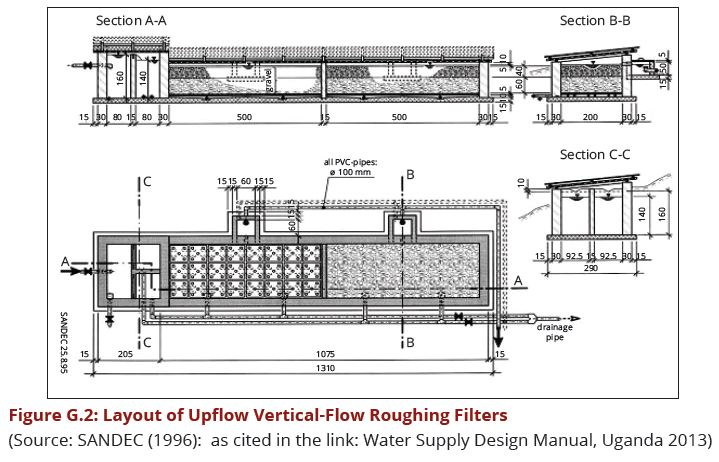

2. Vertical-flow roughing filters

Design guidelines

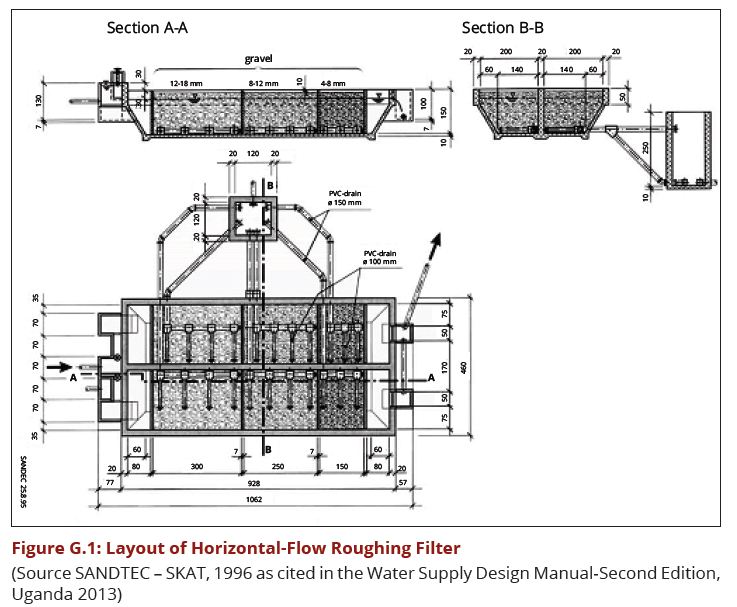

The size of the three distinct filter material fractions is generally between 20 and

4 mm, and graded, for example, into fractions of 12-18 mm, 8-12 mm and 4-8

mm.

The filter layers are covered with a 0.1 m-deep layer of boulders, to avoid exposing the outflow directly to sunlight; this helps to prevent algal growth.

The filtration rate is approximately 0.6 m/h

The water to be treated flows in sequence through the three filter compartments filled with coarse, medium and fine filter material.

Water flows in through an under - drain system on the bottom, usually a perforated PVC pipe, which also permits rapid abstraction during cleaning when the flow direction is reversed (backwashing).

Vertical-flow roughing filters usually consist of three filter units arranged in series and operate either as down flow or up flow filter as shown in the Appendix B.2 (b).

An upflow filter has a round or rectangular shape, with vertical or partially inclined walls, and it is usually about 1.5 m deep. The filter box can be made of bricks, concrete or ferrocement. The under-drains are covered with a layer of coarse gravel, on top of which lie several layers of finer gravel and coarse sand.

Downflow filters have a better performance than upflow filters as the solid particles are more likely to settle on top of the gravel surface in the direction of flow than under counter current conditions.

In down flow roughing filters, the bulk of accumulated solids has to be flushed with a relatively small wash water volume from the soiled filter top through the lower and cleaner filter part to the filter bottom. The opposite is true for upflow roughing filters.

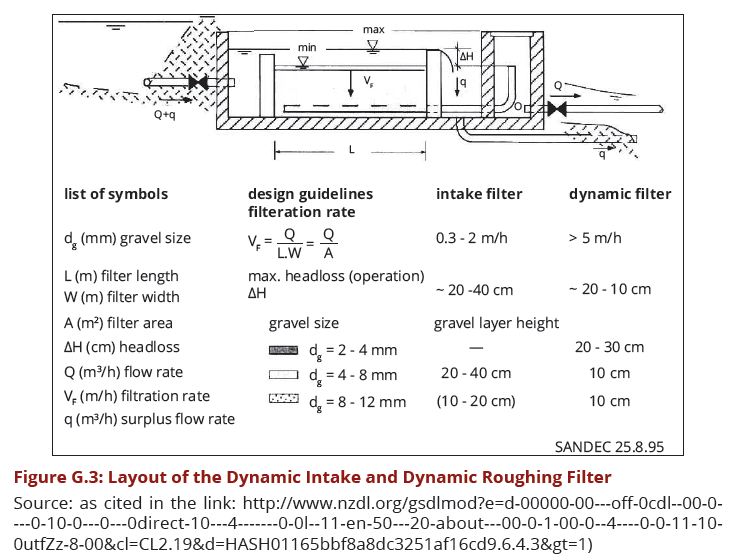

3. Dynamic Roughing Filters

Design guidelines

Maximum available head loss is limited and ranges between 20 and 40 cm in

spite of finer filter material and greater filter velocity.

The water quality between filter inlet and outlet hardly changes during periods of low raw water turbidity.

Dynamic filters act like turbidity meters connected to an open-close valve; i.e., they rapidly get clogged when raw water of high turbidity passes through the filter.

Dynamic filters are similar in layout to intake filters, but differ in filter material size and filtration rate. Especially the gravel size of the top filter layer is smaller; i.e., less than 6 millimetres in diameter, while filtration rate is usually more than 5 m/h.

Finally, the horizontal flow velocity over the filter bed surface should be small or non-existent; i.e., less than 0.05 m/s or nil, to prevent removal of accumulated silt during turbidity peaks. A typical layout of the Dynamic Roughing filter is illustrated in Appendix G.3.

Previous Page: DCOM_Volume_I_Appendix_F << >> Next Page: DCOM_Volume_I_Appendix_H