Difference between revisions of "Chapter Fifteen: Operation and Maintenance of Sanitation Projects"

| Line 127: | Line 127: | ||

The method usually is determined in advance and is normally contingent on the pipe type and size and on the conditions expected in the pipe. | The method usually is determined in advance and is normally contingent on the pipe type and size and on the conditions expected in the pipe. | ||

| − | Record Keeping | + | '''Record Keeping''' |

Record keeping of sewer maintenance, inspections and repairs meets several needs of the sewer system. Records help simplify and improve work planning and scheduling, including integrating recurring and on-demand work. Measuring and tracking of workforce productivity and developing unit costs for various activities are a few of the record keeping benefits. Records of sewer maintenance, service line maintenance, and sewer main and service line repairs should be kept and maintained. | Record keeping of sewer maintenance, inspections and repairs meets several needs of the sewer system. Records help simplify and improve work planning and scheduling, including integrating recurring and on-demand work. Measuring and tracking of workforce productivity and developing unit costs for various activities are a few of the record keeping benefits. Records of sewer maintenance, service line maintenance, and sewer main and service line repairs should be kept and maintained. | ||

| − | + | ===Grease Trap=== | |

| − | |||

| − | |||

| − | |||

Greasy waste that accumulates in the grease trap must be removed regularly. The frequency of cleaning will vary depending on the type of food served and how active one's residence or business is. Regular cleaning keeps a grease trap working properly and will prevent clogging in kitchen drains and pipes. The procedures for grease removal are: | Greasy waste that accumulates in the grease trap must be removed regularly. The frequency of cleaning will vary depending on the type of food served and how active one's residence or business is. Regular cleaning keeps a grease trap working properly and will prevent clogging in kitchen drains and pipes. The procedures for grease removal are: | ||

| − | (a) Inspect the grease trap at least every three days and clean it promptly if the contents show the top 30% of the liquid depth is occupied by greasy waste; | + | (a) Inspect the grease trap at least every three days and clean it promptly if the contents show the top 30% of the liquid depth is occupied by greasy waste;<br> |

| − | (b) Every grease trap is different and must be inspected regularly to determine if cleaning is required. If very little waste builds up in one week or if the surface layer is liquid oil only, the grease trap may not be functioning effectively; | + | (b) Every grease trap is different and must be inspected regularly to determine if cleaning is required. If very little waste builds up in one week or if the surface layer is liquid oil only, the grease trap may not be functioning effectively;<br> |

| − | (c) Check for proper design as outlined in this DCOM Manual and modify or replace the trap if necessary. Small grease traps may be cleaned by hand by scooping the top waste layer into a watertight bag or container or applying hot water; | + | (c) Check for proper design as outlined in this DCOM Manual and modify or replace the trap if necessary. Small grease traps may be cleaned by hand by scooping the top waste layer into a watertight bag or container or applying hot water;<br> |

| − | (d) It is not necessary to empty the grease trap completely; remove only semi-solid layer of greasy waste on the top of the liquid surface; | + | (d) It is not necessary to empty the grease trap completely; remove only semi-solid layer of greasy waste on the top of the liquid surface;<br> |

| − | (e) Clean the trap at a time when wastewater will not be passing through it. Take care not to leave lumps of grease in the trap as this may lead to clogging; | + | (e) Clean the trap at a time when wastewater will not be passing through it. Take care not to leave lumps of grease in the trap as this may lead to clogging;<br> |

| − | (f) Handle the greasy waste carefully to avoid contamination of food preparation or storage areas. Warning signs and safety barriers should be erected around the floor and large grease traps during cleaning; | + | (f) Handle the greasy waste carefully to avoid contamination of food preparation or storage areas. Warning signs and safety barriers should be erected around the floor and large grease traps during cleaning;<br> |

| − | (g) Replace grease trap cover promptly and clean the surrounding area with a disinfectant; | + | (g) Replace grease trap cover promptly and clean the surrounding area with a disinfectant;<br> |

| − | (h) The grease trap waste container should be tightly sealed and disposed of with other kitchen refuse. DO NOT dispose of the grease trap waste in the toilet, gulleys, surface channels or manholes; | + | (h) The grease trap waste container should be tightly sealed and disposed of with other kitchen refuse. DO NOT dispose of the grease trap waste in the toilet, gulleys, surface channels or manholes;<br> |

| − | (i) Record maintenance activities in a log book. Clogging of the inlet or the pipes connecting the two chambers of the grease trap is not a common occurrence but if this happens, any obstruction can be pushed out from the open top of the pipe extending above the liquid surface. Kitchen wastewater also carries pieces of solid waste that are heavier than water. In a grease trap, these solids fall to the bottom and form a layer of settled material. It is necessary to remove this bottom layer of settled waste occasionally; otherwise the grease trap capacity will be reduced. | + | (i) Record maintenance activities in a log book. Clogging of the inlet or the pipes connecting the two chambers of the grease trap is not a common occurrence but if this happens, any obstruction can be pushed out from the open top of the pipe extending above the liquid surface. Kitchen wastewater also carries pieces of solid waste that are heavier than water. In a grease trap, these solids fall to the bottom and form a layer of settled material. It is necessary to remove this bottom layer of settled waste occasionally; otherwise the grease trap capacity will be reduced.<br> |

| − | (j) Carefully remove and dispose of this bottom material in the same manner as for the top layer of greasy waste; | + | (j) Carefully remove and dispose of this bottom material in the same manner as for the top layer of greasy waste;<br> |

| − | (k) Cleaning a grease trap is not a very pleasant job and staff members responsible for this task should be encouraged to carry it out promptly as required and thoroughly. | + | (k) Cleaning a grease trap is not a very pleasant job and staff members responsible for this task should be encouraged to carry it out promptly as required and thoroughly.<br> |

| − | + | ===Screening and Grit Removal=== | |

| − | + | '''Screen''' | |

| − | |||

| − | |||

| − | Screen | ||

Manually cleaned screens require frequent raking to prevent clogging. Cleaning frequency depends on the characteristics of the wastewater entering a plant. Some plants have incorporated screening devices, such as basket-type trash racks, that are manually hoisted and cleaned. Mechanically cleaned screens usually require less labour for operation than manually cleaned screens because screenings are raked with a mechanical device rather than by facility personnel. However, the rake teeth on mechanically cleaned screens must be routinely inspected because of their susceptibility to breakage and bending. Drive mechanisms must also be frequently inspected to prevent fouling due to grit and rags. Grit removed from the screens must be disposed of regularly. | Manually cleaned screens require frequent raking to prevent clogging. Cleaning frequency depends on the characteristics of the wastewater entering a plant. Some plants have incorporated screening devices, such as basket-type trash racks, that are manually hoisted and cleaned. Mechanically cleaned screens usually require less labour for operation than manually cleaned screens because screenings are raked with a mechanical device rather than by facility personnel. However, the rake teeth on mechanically cleaned screens must be routinely inspected because of their susceptibility to breakage and bending. Drive mechanisms must also be frequently inspected to prevent fouling due to grit and rags. Grit removed from the screens must be disposed of regularly. | ||

| Line 157: | Line 151: | ||

A two-step grit removal method is sometimes used, where grit is conveyed horizontally in a trough or channel to a hopper, where it is then elevated from the hopper to another location. Aerated grit chambers use a sloped tank bottom in which the air roll pattern sweeps grit along the bottom to the low side of the chamber. A horizontal screw conveyor is typically used to convey settled grit to a hopper at the head of the tank. Another method to remove grit from the chamber floor is a chain and flight mechanism. Once removed from the chamber, grit is usually washed with a hydro cyclone or grit classifier to ease handling and remove organic material. The grit is then conveyed directly to a truck, dumpster, or storage hopper. From there, the grit is taken to a landfill or other disposal or re-use facility. | A two-step grit removal method is sometimes used, where grit is conveyed horizontally in a trough or channel to a hopper, where it is then elevated from the hopper to another location. Aerated grit chambers use a sloped tank bottom in which the air roll pattern sweeps grit along the bottom to the low side of the chamber. A horizontal screw conveyor is typically used to convey settled grit to a hopper at the head of the tank. Another method to remove grit from the chamber floor is a chain and flight mechanism. Once removed from the chamber, grit is usually washed with a hydro cyclone or grit classifier to ease handling and remove organic material. The grit is then conveyed directly to a truck, dumpster, or storage hopper. From there, the grit is taken to a landfill or other disposal or re-use facility. | ||

| − | + | ===Biogas Settlers=== | |

| − | |||

| − | |||

| − | |||

In settlers that are not designed for anaerobic processes, regular sludge removal is necessary to prevent septic conditions and the build-up and release of gas which can hamper the sedimentation process by re-suspending part of the settled solids. Sludge transported to the surface by gas bubbles is difficult to remove and may pass to the next treatment stage. | In settlers that are not designed for anaerobic processes, regular sludge removal is necessary to prevent septic conditions and the build-up and release of gas which can hamper the sedimentation process by re-suspending part of the settled solids. Sludge transported to the surface by gas bubbles is difficult to remove and may pass to the next treatment stage. | ||

Frequent scum removal and adequate treatment/disposal, either with the sludge or separately, is also important. Anaerobic settlers do have to be emptied less frequently as the organic material is partly transformed into gas. Accumulated slurry in the bottom of the reactor needs to be desludged every two to five years, depending on the type of the reactor (UNEP 2002, MANG 2005). For the operation and maintenance of anaerobic biogas settlers, operational requirements are very low and no professional operator is required as long as the plant is well maintained by skilled users. Starting with the seeding of some sludge from a septic tank or another anaerobic digester speeds up the digestion and prevents the digester from running acid (SASSE, 1998). | Frequent scum removal and adequate treatment/disposal, either with the sludge or separately, is also important. Anaerobic settlers do have to be emptied less frequently as the organic material is partly transformed into gas. Accumulated slurry in the bottom of the reactor needs to be desludged every two to five years, depending on the type of the reactor (UNEP 2002, MANG 2005). For the operation and maintenance of anaerobic biogas settlers, operational requirements are very low and no professional operator is required as long as the plant is well maintained by skilled users. Starting with the seeding of some sludge from a septic tank or another anaerobic digester speeds up the digestion and prevents the digester from running acid (SASSE, 1998). | ||

| − | + | ===Anaerobic Baffled Reactor=== | |

| − | |||

| − | |||

An Anaerobic Baffled Reactor (ABR) requires a start-up period of several months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established in the reactor. To reduce start-up time, the ABR can be inoculated with anaerobic bacteria, e.g., by adding fresh cow dung or septic tank sludge. The added stock of active bacteria can then multiply and adapt to the incoming wastewater. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the ABR. | An Anaerobic Baffled Reactor (ABR) requires a start-up period of several months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established in the reactor. To reduce start-up time, the ABR can be inoculated with anaerobic bacteria, e.g., by adding fresh cow dung or septic tank sludge. The added stock of active bacteria can then multiply and adapt to the incoming wastewater. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the ABR. | ||

Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Process operation in general is not required, and maintenance is limited to the removal of accumulated sludge and scum every 1 to 3 years. This is best done using a motorized emptying and transport technology. The desludging frequency depends on the chosen pre-treatment steps, as well as on the design of the ABR. ABR tanks should be checked from time to time to ensure that they are watertight. | Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Process operation in general is not required, and maintenance is limited to the removal of accumulated sludge and scum every 1 to 3 years. This is best done using a motorized emptying and transport technology. The desludging frequency depends on the chosen pre-treatment steps, as well as on the design of the ABR. ABR tanks should be checked from time to time to ensure that they are watertight. | ||

| − | + | ===Anaerobic Filter=== | |

| − | |||

| − | |||

| − | |||

An anaerobic filter (AF) requires a start-up period of 6 to 9 months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established on the filter media. To reduce start-up time, the filter can be inoculated with anaerobic bacteria, e.g., by spraying Septic Tank sludge onto the filter material. The flow should be gradually increased over time. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the anaerobic filter. Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Over time, solids will clog the pores of the filter. As well, the growing bacterial mass will become too thick, break off and eventually clog pores. When the efficiency decreases, the filter must be cleaned. This is done by running the system in reverse mode (backwashing) or by removing and cleaning the filter material. Anaerobic filter tanks should be checked from time to time to ensure that they are watertight. | An anaerobic filter (AF) requires a start-up period of 6 to 9 months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established on the filter media. To reduce start-up time, the filter can be inoculated with anaerobic bacteria, e.g., by spraying Septic Tank sludge onto the filter material. The flow should be gradually increased over time. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the anaerobic filter. Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Over time, solids will clog the pores of the filter. As well, the growing bacterial mass will become too thick, break off and eventually clog pores. When the efficiency decreases, the filter must be cleaned. This is done by running the system in reverse mode (backwashing) or by removing and cleaning the filter material. Anaerobic filter tanks should be checked from time to time to ensure that they are watertight. | ||

| − | + | ===Up-flow Anaerobic Sludge Blanket Reactor=== | |

| − | |||

| − | |||

| − | |||

The Up-flow Anaerobic Sludge Blanket (UASB) is a Centralized Treatment technology that must be operated and maintained by professionals. A skilled operator is required to monitor the reactor and repair parts, e.g., pumps, in case of problems. Desludging is infrequent and only excess sludge is removed every 2 to 3 years. | The Up-flow Anaerobic Sludge Blanket (UASB) is a Centralized Treatment technology that must be operated and maintained by professionals. A skilled operator is required to monitor the reactor and repair parts, e.g., pumps, in case of problems. Desludging is infrequent and only excess sludge is removed every 2 to 3 years. | ||

| − | + | ===Settling-thickening tanks=== | |

| − | |||

| − | |||

| − | |||

Constant monitoring and adaption accordingly are always required. In the design phase a series of assumptions are made in order to design the operation. The operation cycle consists of 1) faecal sludge loading, 2) thickened faecal sludge compaction, and 3) bottom sludge and scum removal. Pump failure is a common issue so it is important that it is installed in such a way that it can be accessed without pumping out the tank contents. Pumps should be selected based on the solids concentration of the thickened layer and available energy source. To alleviate frequent problems with pumping, solids are frequently removed by front loaders. Designing for manual removal using shovels is not recommended due to the difficult nature of removal. | Constant monitoring and adaption accordingly are always required. In the design phase a series of assumptions are made in order to design the operation. The operation cycle consists of 1) faecal sludge loading, 2) thickened faecal sludge compaction, and 3) bottom sludge and scum removal. Pump failure is a common issue so it is important that it is installed in such a way that it can be accessed without pumping out the tank contents. Pumps should be selected based on the solids concentration of the thickened layer and available energy source. To alleviate frequent problems with pumping, solids are frequently removed by front loaders. Designing for manual removal using shovels is not recommended due to the difficult nature of removal. | ||

The Total Suspended Solids (TSS) concentration of the supernatant will guide one in the treatment performance of the settling-thickening tank. If the TSS concentration is not suitable for the subsequent effluent treatment technology, a change in design, incoming faecal sludge, inlet/outlet design and/or more frequent desludging might be required. | The Total Suspended Solids (TSS) concentration of the supernatant will guide one in the treatment performance of the settling-thickening tank. If the TSS concentration is not suitable for the subsequent effluent treatment technology, a change in design, incoming faecal sludge, inlet/outlet design and/or more frequent desludging might be required. | ||

| − | + | ===Unplanted Sludge drying beds=== | |

| − | |||

| − | |||

| − | |||

Operation and maintenance to consider for unplanted sludge drying beds include: | Operation and maintenance to consider for unplanted sludge drying beds include: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | (a) Sand and gravel must be washed prior to placing it in the filter to remove dust particles which could cause clogging of the beds,<br> | ||

| + | (b) When loading it is very important not to exceed the recommended loading rates (hydraulic or solids),<br> | ||

| + | (c) Faecal sludge can only be loaded onto the sludge drying beds once during each drying cycle. Partially dewatered faecal sludge forms a crust on the surface that prevents liquid from passing down to the sand layer and percolating through the drying bed,<br> | ||

| + | (d) Incorrect loading can lead to ponding or clogging of beds. If clogging occurs, the entire sand and gravel layer needs to be washed or replaced,<br> | ||

| + | (e) Solids removal is labour intensive, so adequate time needs to be estimated to ensure that loading cycles can be maintained,<br> | ||

| + | (f) During solids removal, measures need to be taken to minimize the sand loss, as the sand layer is slowly removed, it needs to be replaced,<br> | ||

| + | (g) Electrical operation and maintenance must be included if pumps are used for loading of the drying beds. Examples are spare parts and fuel,<br> | ||

| + | (h) It is important to monitor the leachate as an indicator of the sludge drying bed performance (e.g. total volumes, TS concentration).<br> | ||

| + | ===Planted Sludge Drying Beds=== | ||

The following list presents key considerations for operation and maintenance of planted sludge drying beds: | The following list presents key considerations for operation and maintenance of planted sludge drying beds: | ||

| − | (a) It is important to have trained operators who operate and maintain the sludge drying beds, especially during the acclimation period; | + | (a) It is important to have trained operators who operate and maintain the sludge drying beds, especially during the acclimation period;<br> |

| − | (b) During loading, make sure the faecal sludge is well distributed, especially during the start-up to ensure the filter media is not disturbed; | + | (b) During loading, make sure the faecal sludge is well distributed, especially during the start-up to ensure the filter media is not disturbed;<br> |

| − | (c) Plant survival is crucial for treatment performance; | + | (c) Plant survival is crucial for treatment performance;<br> |

| − | (d) During the start-up, the solids loading rates and feeding intervals need to be further evaluated to ensure adequate frequencies and loadings for plant health; | + | (d) During the start-up, the solids loading rates and feeding intervals need to be further evaluated to ensure adequate frequencies and loadings for plant health;<br> |

| − | (e) Optimal plant densities and harvesting frequencies should be evaluated; | + | (e) Optimal plant densities and harvesting frequencies should be evaluated;<br> |

| − | (f) Harvest plants by cutting them at the surface; avoid pulling them out because this will damage the root system and drying bed filter material; | + | (f) Harvest plants by cutting them at the surface; avoid pulling them out because this will damage the root system and drying bed filter material;<br> |

| − | (g) Monitor the drainage system and effluent for treatment performance and any possible changes; | + | (g) Monitor the drainage system and effluent for treatment performance and any possible changes;<br> |

| − | (h) Remember that wildlife might be attracted to the plants, so fencing and measures to decrease possible vector-borne diseases might be required. | + | (h) Remember that wildlife might be attracted to the plants, so fencing and measures to decrease possible vector-borne diseases might be required.<br> |

| − | + | ===Co-composting=== | |

| − | |||

| − | |||

| − | |||

Co-composting needs to be monitored continuously in order to ensure adequate temperature and moisture content to achieve the treatment objectives. In addition, specific operational and maintenance concerns include: | Co-composting needs to be monitored continuously in order to ensure adequate temperature and moisture content to achieve the treatment objectives. In addition, specific operational and maintenance concerns include: | ||

| − | (a) When turning the pile, all parts must be exposed to a high temperature in order to kill off the pathogens, | + | (a) When turning the pile, all parts must be exposed to a high temperature in order to kill off the pathogens,<br> |

| − | (b) The temperature is regulated by turning the pile more often if the temperature is too high. If too low, more water potentially needs to be added and/or the mass of moist input material needs to be increased, | + | (b) The temperature is regulated by turning the pile more often if the temperature is too high. If too low, more water potentially needs to be added and/or the mass of moist input material needs to be increased,<br> |

| − | (c) The aerobic condition in the pile is facilitated by the heap-turning frequency, which is context-dependent and needs to be determined by trial and error, | + | (c) The aerobic condition in the pile is facilitated by the heap-turning frequency, which is context-dependent and needs to be determined by trial and error,<br> |

| − | (d) Mycelium (clumps of white threads) and small insects are present to break down complex organic material and particles, | + | (d) Mycelium (clumps of white threads) and small insects are present to break down complex organic material and particles,<br> |

| − | (e) Odour problems can be a sign of too high a moisture content and can be reduced by increased turning and the addition of coarse material, | + | (e) Odour problems can be a sign of too high a moisture content and can be reduced by increased turning and the addition of coarse material,<br> |

| − | (f) It may be necessary to cover co-compost piles to either protect from, or to maintain, humidity, | + | (f) It may be necessary to cover co-compost piles to either protect from, or to maintain, humidity,<br> |

| − | (g) Large amounts of flies, insects and rodents must be avoided. Covering the pile could reduce the number of flies, insects and rodents gathering, | + | (g) Large amounts of flies, insects and rodents must be avoided. Covering the pile could reduce the number of flies, insects and rodents gathering,<br> |

| − | (h) Compost as a product is sieved to separate coarse and fine compost. The coarse compost is re-used in the next round of co-composting while the fine compost is ready to be used as a soil amendment. | + | (h) Compost as a product is sieved to separate coarse and fine compost. The coarse compost is re-used in the next round of co-composting while the fine compost is ready to be used as a soil amendment.<br> |

| − | + | ===Co-treatment of Faecal Sludge with Wastewater=== | |

| − | |||

| − | |||

| − | |||

Implementation of co-treatment needs to be carefully monitored. Re-evaluate the treatment capacity and performance frequently to monitor for any unforeseen change in influent values. The risk of failure cannot be stressed enough, as co-treatment has been the cause of many treatment plant failures. | Implementation of co-treatment needs to be carefully monitored. Re-evaluate the treatment capacity and performance frequently to monitor for any unforeseen change in influent values. The risk of failure cannot be stressed enough, as co-treatment has been the cause of many treatment plant failures. | ||

| − | + | ===Effluent Treatment Technologies=== | |

| − | |||

| − | |||

| − | |||

The operation and maintenance of the effluent treatment has to be carried out by qualified staff according to the selected treatment options, for example, if the biological nature of the treatment is complex and sensitive to inflow fluctuation. If transferring or innovative technologies are selected, they need to be closely monitored so that the operation can be adapted as needed. | The operation and maintenance of the effluent treatment has to be carried out by qualified staff according to the selected treatment options, for example, if the biological nature of the treatment is complex and sensitive to inflow fluctuation. If transferring or innovative technologies are selected, they need to be closely monitored so that the operation can be adapted as needed. | ||

| − | + | ===Waste Stabilization Ponds=== | |

| − | |||

| − | |||

| − | |||

Operation and maintenance of waste stabilization ponds | Operation and maintenance of waste stabilization ponds | ||

The operation of the waste stabilization ponds (WSPs) includes the commissioning (starting up), maintaining and monitoring its performance. | The operation of the waste stabilization ponds (WSPs) includes the commissioning (starting up), maintaining and monitoring its performance. | ||

| − | Starting up of waste stabilization ponds | + | '''Starting up of waste stabilization ponds''' |

Anaerobic ponds have to be filled with raw sewage and seeded with sludge from conventional sewage treatment plant or septic tank. After filling and seeding then the pond should be gradually loaded up to the design-loading rate. The pond contents should have a pH above 7 to allow the development of methanogenic bacteria. Add lime or soda ash to rise the pH in the pond if necessary. If the sewerage system is new and the flow rate as well as the loading rate to the anaerobic pond is low, then the sewage may be by-passed till the flow rate and the loading rate from the sewerage systems satisfies the condition to be discharged in the WSP. It is important to have by-pass from the anaerobic pond that will be used during desludging. It is also recommended to commission the WSPs during the beginning of the hot season so as to allow quick establishment of microorganisms of importance for the waste stabilization ponds. | Anaerobic ponds have to be filled with raw sewage and seeded with sludge from conventional sewage treatment plant or septic tank. After filling and seeding then the pond should be gradually loaded up to the design-loading rate. The pond contents should have a pH above 7 to allow the development of methanogenic bacteria. Add lime or soda ash to rise the pH in the pond if necessary. If the sewerage system is new and the flow rate as well as the loading rate to the anaerobic pond is low, then the sewage may be by-passed till the flow rate and the loading rate from the sewerage systems satisfies the condition to be discharged in the WSP. It is important to have by-pass from the anaerobic pond that will be used during desludging. It is also recommended to commission the WSPs during the beginning of the hot season so as to allow quick establishment of microorganisms of importance for the waste stabilization ponds. | ||

The facultative WSP should be commissioned before the anaerobic WSP in order to avoid odour during the release of anaerobic pond effluent to an empty facultative WSP. During the start-up of the facultative and maturation WSPs, they should be filled with freshwater (from tap, river or wells). This will allow gradual development of algae and heterotrophic bacteria population. However, primary facultative ponds must be seeded as the anaerobic WSP. If fresh water is not available, the secondary facultative and maturation WSPs should be filled with raw sewage and leave them for three to four weeks to allow development of the microbial population. | The facultative WSP should be commissioned before the anaerobic WSP in order to avoid odour during the release of anaerobic pond effluent to an empty facultative WSP. During the start-up of the facultative and maturation WSPs, they should be filled with freshwater (from tap, river or wells). This will allow gradual development of algae and heterotrophic bacteria population. However, primary facultative ponds must be seeded as the anaerobic WSP. If fresh water is not available, the secondary facultative and maturation WSPs should be filled with raw sewage and leave them for three to four weeks to allow development of the microbial population. | ||

| − | Maintenance | + | '''Maintenance''' |

Maintenance for the WSPs should be carried regularly to avoid odour, flies and mosquitoes nuisance. The routine maintenance involves: | Maintenance for the WSPs should be carried regularly to avoid odour, flies and mosquitoes nuisance. The routine maintenance involves: | ||

| − | (a) Removal of screenings and grit from the inlets and outlets works, | + | |

| − | (b) Cutting grass on the embankment and removing it so that it should not fall in the WSPs, | + | (a) Removal of screenings and grit from the inlets and outlets works,<br> |

| − | (c) Removing floating scum and floating macrophytes from the surface of the maturation and facultative WSPs, | + | (b) Cutting grass on the embankment and removing it so that it should not fall in the WSPs,<br> |

| − | (d) Spraying scum on the surface of anaerobic WSPs and should not be removed as it helps the treatment processes, | + | (c) Removing floating scum and floating macrophytes from the surface of the maturation and facultative WSPs,<br> |

| − | (e) Removal of any accumulated solids in the inlets and outlet works, | + | (d) Spraying scum on the surface of anaerobic WSPs and should not be removed as it helps the treatment processes,<br> |

| − | (f) Repair any damaged embankment as soon as possible, | + | (e) Removal of any accumulated solids in the inlets and outlet works,<br> |

| − | (g) Repair any damage on fence and gate. | + | (f) Repair any damaged embankment as soon as possible,<br> |

| + | (g) Repair any damage on fence and gate.<br> | ||

The operator must be given precise information on what to do at the WSP site. A clear form should be prepared showing the tasks to be performed by the operator that should be counter-checked by the foreman/supervisor weekly. Mara (1987) recommends that, for proper operation of the WSPs there should be a manager, assistant manager, engineers, works foreman, laboratory chemist, assistant laboratory chemist, technicians, artisan and the clerk. The number of staff depends on how extensive the project is and also on the population served as well as the degree of mechanisation aspired for. | The operator must be given precise information on what to do at the WSP site. A clear form should be prepared showing the tasks to be performed by the operator that should be counter-checked by the foreman/supervisor weekly. Mara (1987) recommends that, for proper operation of the WSPs there should be a manager, assistant manager, engineers, works foreman, laboratory chemist, assistant laboratory chemist, technicians, artisan and the clerk. The number of staff depends on how extensive the project is and also on the population served as well as the degree of mechanisation aspired for. | ||

| Line 261: | Line 226: | ||

Anaerobic WSPs requires desludging when they are one third full of the sludge by volume. | Anaerobic WSPs requires desludging when they are one third full of the sludge by volume. | ||

| − | + | n=V/3Ps (15.1) | |

Where, V is the volume of the anaerobic pond (m3), P is the population served, s is the sludge accumulation rate (m3/person year) and n is the interval in years (every few years). | Where, V is the volume of the anaerobic pond (m3), P is the population served, s is the sludge accumulation rate (m3/person year) and n is the interval in years (every few years). | ||

Revision as of 14:11, 19 July 2022

Contents

- 1 Chapter Fifteen Operation and Maintenance of Sanitation Projects

- 1.1 Operation and Maintenance Requirements for Sanitation System

- 1.2 Capacity Building to Ensure Proper Operation and Maintenance

- 1.3 Organizing and Planning Operation and Maintenance

- 1.4 Operation and Maintenance requirements for Sanitation Units

- 1.4.1 Septic Tank

- 1.4.2 Sewers

- 1.4.3 Grease Trap

- 1.4.4 Screening and Grit Removal

- 1.4.5 Biogas Settlers

- 1.4.6 Anaerobic Baffled Reactor

- 1.4.7 Anaerobic Filter

- 1.4.8 Up-flow Anaerobic Sludge Blanket Reactor

- 1.4.9 Settling-thickening tanks

- 1.4.10 Unplanted Sludge drying beds

- 1.4.11 Planted Sludge Drying Beds

- 1.4.12 Co-composting

- 1.4.13 Co-treatment of Faecal Sludge with Wastewater

- 1.4.14 Effluent Treatment Technologies

- 1.4.15 Waste Stabilization Ponds

1 Chapter Fifteen Operation and Maintenance of Sanitation Projects

1.1 Operation and Maintenance Requirements for Sanitation System

Operation and maintenance (O&M) activities, encompass not only technical issues, but also managerial, social, financial and institutional issues, must be directed towards the elimination or reduction of the major constraints which prevent the achievement of sustainability (Brikke, 2000). Operation and maintenance is a crucial element of sustainability and a frequent cause of failure of sanitation service facilities in the past. Many failures are not caused by technical reasons only, they may also result from poor planning, inadequate cost recovery, or the outreach inadequacies of centralised agencies (DfID, 1998).

Operation and maintenance has been neglected in the past, it has been discussed and introduced after a project completion. This neglect or delay in applying proper operation and maintenance has adversely affected the credibility of the investments made, the functioning of the services, the well-being of rural populations, and the development of further projects. However, the importance of O&M has gained considerable visibility over the past few years, and it appears that policy-makers and project designers are now more conscious of the direct links between improved O&M practices and the sustainability of sanitation services. There is also greater recognition of the need to approach these projects in a comprehensive way, emphasizing not only the design and construction but also post-construction activities (Brikke, 2000).

1.1.1 Design for Operation and Maintenance

The ease of operation and maintenance of a facility is central to its sustainability and must be given careful consideration in design. Some operation and maintenance issues are location-specific, but urban and rural projects differ fundamentally in the complexity of the technologies involved. In rural areas, the concept of Village Level Operation and Maintenance Management (VLOM) is a philosophy which has been gaining favour over the years. The VLOM approach restricts technology choices to those that can be operated and maintained within the community for which the intervention is intended. In urban situations, where supply systems will generally be more complex, the design and technology chosen will shape the long-term operation and maintenance requirements. When designing a sewerage system, the engineer must, for instance, take into account operation and maintenance factors such as the availability of chemicals for treatment, spare parts, and equipment, the reliability of power supplies, and the availability of local skills and capacity to undertake O&M.

The standardization of equipment, parts, designs, construction methods, etc., has many benefits. It makes design simpler as choices are made from a limited range of options. In the short term, this may marginally increase construction costs as the standard designs may not be perfectly suited to the situation. But it requires lower skill levels in the design process, and repetitive construction of the same item improves quality. Operation and maintenance benefits too: Limiting the range of spare parts increases the quantity of each item that is required (i.e. more of a few items rather than less of many). This encourages local manufacture because the limited range reduces start-up costs and the increased quantity improves profitability. Standardization also reduces the number of skills required to install and maintain the piece of equipment, thus increasing the probability of local craftsmen being able to carry out the work.

==Community Management for Operation and Maintenance In order to ensure the sustainability of the sanitation and improved sanitation solution, it is necessary to have a community ownership and management approach, making the end-users directly responsible for the operation and maintenance of the installed facilities. Successful operation and maintenance requires following an “owner’s manual” prepared by the contractor and engineer at the onset of the planning process. This should spell out a schedule and procedures for maintenance and should also include methods to carry out tasks, such as book-keeping, paying employees, collecting bills (utility management), inspection, replacement of parts, etc., giving an integral framework for operation and maintenance (NETSSAF, 2008).

1.2 Capacity Building to Ensure Proper Operation and Maintenance

Households and members of the community need to be informed about the system that has been put in place for a proper operation. When new user-interfaces or management approaches have been introduced, such as Urine Diversion Dehydration Toilets (UDDT) or a new system for composting of kitchen waste, which heavily relies on the correct operation from the user’s side, the end-users have to be properly trained to ensure that they will operate the systems correctly.

At district level, communities and their organizations (Community-Based Water Supply Organizations - CBWSOs) that will undertake O&M and/or management of local infrastructure need training on technical matters, accounting and simple financial management, basic contract procedures, and monitoring and reporting. NGOs that will become involved in the programme need similar training, but at a more advanced level, as they are probably going to have to train the participating communities (EAWAG 2005).

Local operators and caretakers need to be trained for the proper operation of the new infrastructure. In this case, hands-on training is desired in order to ensure the full understanding and the awareness of the implications of the new system. Private operators or local engineering companies that will take care of the maintenance of the sanitation systems should be also trained in the type of maintenance activities that have to be carried out periodically.

1.3 Organizing and Planning Operation and Maintenance

Organizing for O&M does not represent a huge task, but it does require a certain level of planning, commitment and monitoring. The aspects to be organized are:

- What: the activity which is to be carried out

- When: the frequency of this activity

- Who: the human resources required for the task

- With what: what are the materials, spare parts, tools and equipment needed

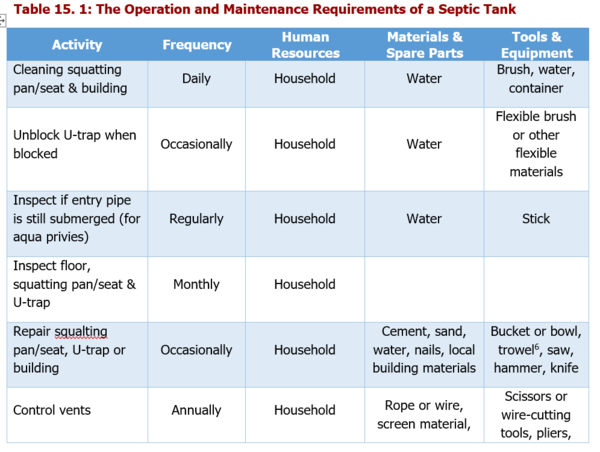

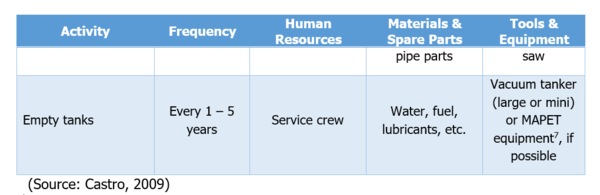

Table 15.1 gives an idea of the type of tools which have to be developed to support the operation and maintenance of the envisaged new sanitation infrastructure. The example relates to the O&M of a septic tank (adapted from Castro, 2009):

Applicability Operation and maintenance is required to ensure the sustainability of any project in which a new infrastructure has been put into place.

1.4 Operation and Maintenance requirements for Sanitation Units

Different sanitation units have different operation and maintenance requirements. This section presents O and M requirements for different sanitation units.

1.4.1 Septic Tank

Operation

The daily discharges made from a property into a septic tank or treatment plant will affect the efficiency of the system. Discharges of disinfectants and strong chemicals will kill bacteria in the tank and hence prevent the decomposition of the solids. It is therefore very important to consider the effects of cleansing products on the bacteria. A simple list is given below to highlight measures that will improve the efficiency of a septic tank:

(a) Discharges of rainwater to the septic tank are not recommended. The turbulence caused by the high flows will disturb solids in the vessel and allow them to be carried out into the ground (causing the soak away to block). Rainwater also causes considerable dilution of the bacterial matter thereby reducing the efficiency of the tank. If possible rainwater should be drained to a surface water drain, stream or separate soak away,

(b) Prevent the discharge of non-degradable matter into the tank, such as nappies, condoms, sanitary towels, etc. that will not decompose. Avoid all discharges of oils and cooking fats, which will congeal inside the tank and will not be digested by the bacteria. Oils entering the tank from washing up can largely be ignored,

(c) Volatile liquids such as petrol, acetone, methylated spirits, paraffin, etc. must never be discharged into the drainage system mainly due to their high flammability,

(d) Chemical discharges including cleaning agents have considerable effects on the bacterial treatment of sewage dependent upon their concentration, quantity and frequency of use. With mild detergents such as washing powders, etc. a minimum dilution factor of 50 parts water to 1 part detergent is recommended. Whilst good personal hygiene should always be maintained, disinfectants, acids, bleaches, chlorine and strong detergents must only be used where absolutely necessary.

Maintenance Periodically the sludge and scum will build-up to such an extent that it needs removing. The frequency of these sludge removal visits is dependent on the use, size and type of the septic tank. As a general guide older brick or concrete structures (often fitted with rectangular metal covers) will require emptying approximately once every 2 years, whilst fiberglass tanks (often fitted with diamond shaped access covers) or pre-cast concrete cylindrical tanks will need emptying at least every 12 months. A traditional septic tank contains no mechanical parts and should not require any other regular maintenance unless problems occur. It is a good idea when emptying brick / concrete tanks to leave the top layer of sludge within the vessel and to remove the solids from the base of the tank. This allows the bacteria to quickly re-establish when the tank fills again. Modern packaged sewage treatment plants are likely to require more frequent emptying (at least once every 6 months). These systems will also require the servicing of any mechanical parts within the vessel. It is recommended that the manufacturers’ advice be sought on the maintenance of these plants. Most large drainage contractors offer a septic tank emptying service and there is a wide range of companies advertising in the classified directories that may also be able to carry out appropriate servicing on packaged sewage treatment plants. In Tanzania, the emptying services are offered by both the municipal or town councils or private providers.

1.4.2 Sewers

Consistent and thorough maintenance of the collection system will enable the system to serve its stated life. Preventive maintenance is talked about, but seldom practiced by some agencies. Decades of neglect, or grossly inadequate maintenance of some systems, are two reasons why wastewater collection systems now require billions of dollars worth of rehabilitation and upgrading over the next 20 years.

Cause of sewer dysfunctions:

(a) Collection systems and service connections were not installed as designed. Problems are caused by faulty construction, poor inspection and low-bid shortcuts,

(b) The pipe joints were made rigid. Earth movement, vibration from traffic, settling of structures and construction disturbance (all occur from time to time) require a flexible pipe material or joint that can maintain tightness. Joints had opened, cracked and/or sheared thus allowing debris and infiltration into the sewer,

(c) Corrosion of sewer pipes and manholes from either the trench bedding and backfill or the wastewater being transported by the collection system was a factor neglected during design. A major cause of corrosion in wastewater collection systems and treatment plants is hydrogen sulphide gas,

(d) Potential damage to pipe joints by plant roots was not known or was neglected during design. Although root intrusion into sewers is age-old, it was assumed that if the joint was watertight, it would be root tight. People did not realize that roots would be attracted by moisture and nutrient vapour unless the joints were vapour tight (which means airtight). Roots can enter a pipe joint or walls microscopically (through extremely small holes or cracks); thus, open or leaking joints are not necessary for root intrusion in collection systems,

(e) Collection system environments are ideal for root growth. In this environment, roots enter, expand and open joints and cracks. Root growth is a principal cause of pipe damage that allows infiltration and exfiltration. This creates a major concern for health and pollution control authorities because of wastewater treatment plant overload and groundwater pollution,

(f) The out of sight, out of mind nature of wastewater collection system. Local taxpayers have invested more money in underground sewers why has this great taxpayer investment been so grossly neglected? Because it is out of sight, and so, out of mind,

(g) Poor records regarding complaints from the public or the date and location of stoppages that had to be cleared can result in an ineffective maintenance programme. Good records, regular analysis of the records, and use of this information can produce a cost-effective preventive maintenance programme.

Operation and maintenance of wastewater collection systems in an emergency basis has been the usual procedure and policy in many communities and districts. Planned operation and preventive maintenance of the collection system has been delayed or omitted, in spite of desires by collection system operators. Municipal officials tend to neglect collection systems as long as complaints are not excessive. To please constituents, officials often demand street and sidewalk repairs to be done by collection system crews, but seldom have they ever demanded preventive work on the collection systems.

Inspection and testing are the techniques used to gather information to develop operation and maintenance programmes to ensure that new and existing wastewater collection systems serve their intended purposes on a continuing basis. Inspection and testing are necessary to do the following:

(a) Identify existing or potential problem areas in the collection system,

(b) Evaluate the seriousness of the detected problems,

(c) Locate the position of problems, and

(d) Provide clear, concise and meaningful reports regarding the observed problems.

Sewer Leakage Control Leaky sewers have to be considered as potential sources for groundwater contamination in urban areas. Two major purposes of inspecting and testing are to prevent leaks from developing in the wastewater collection system and to identify existing leaks so they can be corrected. The existence of leaks in a wastewater collection system is a serious and often expensive problem. When a sewer is located below under a water table, infiltration can take place and occupy valuable capacity in the sewer and the downstream treatment plant. Sewers located above a water table can ex-filtrate, allowing raw wastewater to pollute the soil and groundwater.

Guidance for manhole inspections and sewer inspections are presented herein. The information provided if employed is a good starting point for an inspection. Manhole inspections should yield a report with the following information at the minimum:

(a) Exact location of the manhole;

(b) Diameter of the clear opening of the manhole;

(c) Condition of the cover and frame, including defects that would allow inflow to enter the system;

(d) Whether cover is subject to ponding or surface runoff;

(e) The potential drainage area tributary to the defects;

(f) Type of material and condition of the chimney corbel cone and walls;

(g) Condition of steps and chimney and frame-chimney joint;

(h) Configuration of the incoming and outgoing lines (including drops); and

(i) Signs of frame-chimney leakage or damage to the frame’s seal.

Additionally, the following data can be obtained by entering the manhole and using equipment such as CCTV, portable lamps, mirrors, rulers, and probe rods:

(a) Type of material and condition of apron and trough;

(b) Any observed infiltration sources and the rate of infiltration;

(c) Indications of height of surcharge;

(d) Size and type of all incoming and outgoing lines; and

(e) Depth of flow indications of deposition and the characteristics of flow within all pipes.

(f) The condition of the manhole shaft;

(g) Any leakage in the channel;

(h) Any leakage between the manhole wall and the channel;

(i) Any damage or leakage where pipeline connects to the manhole; and

(j) Any flow obstructions.

Planning is required to define the inspections goals. Inspections are performed to:

(a) Identify maintenance problems,

(b) Determine general sewer conditions,

(c) Identify extraneous flows.

Methods for Controlling Sewer Leaks Methods for controlling leaks in the sewer collection system can be summarized as follows:

(a) Chemical grouting: A soil sealing process which employs a two-part liquid chemical grout that solidifies after curing. The grout is remotely applied under pressure to leaking joints or laterals and small cracks in sewers and manholes to seal the voids within the soil surrounding the exterior of the pipe at the point of leakage,

(b) CIPP (cured-in-place) lining: An internal liner is formed by inserting a resin-impregnated felt tube through the manhole into the sewer. The liner is then expanded against the inner wall of the existing pipe and allowed to cure,

(c) Fold and form liner: A folded thermoplastic pipe is pulled into place through a manhole and then rounded, using heat, steam and air pressure to conform to the internal diameter of the existing pipe,

(d) Slip lining: An access pit is excavated adjacent to an existing sewer and a liner pipe of slightly smaller diameter is slid into the existing pipe to create a continuous, watertight liner between the two manholes,

(e) Pipe bursting: An access pit is excavated adjacent to an existing sewer and the pipe is broken outward by means of an expansion tool. A flexible liner pipe of equal or larger diameter is pulled behind the bursting device as a replacement sewer.

It is important to take note that, with exception of the chemical grouting, the other methods are more expensive. Sewer Cleaning The purpose of sewer cleaning is to remove foreign material from the sewer and generally is undertaken to alleviate one of the following conditions:

(a) Blockages (semisolid obstructions resulting in a virtual cessation of flow). These generally are dealt with on an emergency basis, although the underlying cause can be treated pre-emptively;

(b) Hydraulic capacity. In some cases, sediment, roots, intrusions (connections or other foreign bodies), grease, encrustation and other foreign material restrict the capacity of a sewer, causing surcharge or flooding. Cleaning the sewer may alleviate these problems permanently, or at least temporarily;

(c) Pollution caused by either the premature operation of combined wastewater overflows because of downstream restrictions to hydraulic capacity or pollution caused by the washing through and discharge of debris from overflows during storms;

(d) Odour caused by the retention of solids in the system for long periods resulting in, among other things, wastewater turning septic and producing hydrogen sulphide;

(e) Sewer inspections, where the sewer needs to be cleaned before inspection. This requirement most often occurs when using in-sewer CCTV inspection techniques;

(f) Sewer rehabilitation where it is necessary to clean the sewers immediately before the sewer being rehabilitated.

Common sewer cleaning methods include:

(a) Jet rodding,

(b) Manual rodding,

(c) Winching or dragging,

(d) Cutting, and

(e) Manual or mechanical digging.

The method usually is determined in advance and is normally contingent on the pipe type and size and on the conditions expected in the pipe.

Record Keeping Record keeping of sewer maintenance, inspections and repairs meets several needs of the sewer system. Records help simplify and improve work planning and scheduling, including integrating recurring and on-demand work. Measuring and tracking of workforce productivity and developing unit costs for various activities are a few of the record keeping benefits. Records of sewer maintenance, service line maintenance, and sewer main and service line repairs should be kept and maintained.

1.4.3 Grease Trap

Greasy waste that accumulates in the grease trap must be removed regularly. The frequency of cleaning will vary depending on the type of food served and how active one's residence or business is. Regular cleaning keeps a grease trap working properly and will prevent clogging in kitchen drains and pipes. The procedures for grease removal are:

(a) Inspect the grease trap at least every three days and clean it promptly if the contents show the top 30% of the liquid depth is occupied by greasy waste;

(b) Every grease trap is different and must be inspected regularly to determine if cleaning is required. If very little waste builds up in one week or if the surface layer is liquid oil only, the grease trap may not be functioning effectively;

(c) Check for proper design as outlined in this DCOM Manual and modify or replace the trap if necessary. Small grease traps may be cleaned by hand by scooping the top waste layer into a watertight bag or container or applying hot water;

(d) It is not necessary to empty the grease trap completely; remove only semi-solid layer of greasy waste on the top of the liquid surface;

(e) Clean the trap at a time when wastewater will not be passing through it. Take care not to leave lumps of grease in the trap as this may lead to clogging;

(f) Handle the greasy waste carefully to avoid contamination of food preparation or storage areas. Warning signs and safety barriers should be erected around the floor and large grease traps during cleaning;

(g) Replace grease trap cover promptly and clean the surrounding area with a disinfectant;

(h) The grease trap waste container should be tightly sealed and disposed of with other kitchen refuse. DO NOT dispose of the grease trap waste in the toilet, gulleys, surface channels or manholes;

(i) Record maintenance activities in a log book. Clogging of the inlet or the pipes connecting the two chambers of the grease trap is not a common occurrence but if this happens, any obstruction can be pushed out from the open top of the pipe extending above the liquid surface. Kitchen wastewater also carries pieces of solid waste that are heavier than water. In a grease trap, these solids fall to the bottom and form a layer of settled material. It is necessary to remove this bottom layer of settled waste occasionally; otherwise the grease trap capacity will be reduced.

(j) Carefully remove and dispose of this bottom material in the same manner as for the top layer of greasy waste;

(k) Cleaning a grease trap is not a very pleasant job and staff members responsible for this task should be encouraged to carry it out promptly as required and thoroughly.

1.4.4 Screening and Grit Removal

Screen Manually cleaned screens require frequent raking to prevent clogging. Cleaning frequency depends on the characteristics of the wastewater entering a plant. Some plants have incorporated screening devices, such as basket-type trash racks, that are manually hoisted and cleaned. Mechanically cleaned screens usually require less labour for operation than manually cleaned screens because screenings are raked with a mechanical device rather than by facility personnel. However, the rake teeth on mechanically cleaned screens must be routinely inspected because of their susceptibility to breakage and bending. Drive mechanisms must also be frequently inspected to prevent fouling due to grit and rags. Grit removed from the screens must be disposed of regularly.

Grit Removal Collected grit must be removed from the chamber, dewatered, washed, and conveyed to a disposal or re-use site. Some smaller plants use manual methods to remove grit, but grit removal is usually accomplished by an automatic method. The four methods of automatic grit removal include inclined screw or tubular conveyors, chain and bucket elevators, clamshell buckets, and pumping.

A two-step grit removal method is sometimes used, where grit is conveyed horizontally in a trough or channel to a hopper, where it is then elevated from the hopper to another location. Aerated grit chambers use a sloped tank bottom in which the air roll pattern sweeps grit along the bottom to the low side of the chamber. A horizontal screw conveyor is typically used to convey settled grit to a hopper at the head of the tank. Another method to remove grit from the chamber floor is a chain and flight mechanism. Once removed from the chamber, grit is usually washed with a hydro cyclone or grit classifier to ease handling and remove organic material. The grit is then conveyed directly to a truck, dumpster, or storage hopper. From there, the grit is taken to a landfill or other disposal or re-use facility.

1.4.5 Biogas Settlers

In settlers that are not designed for anaerobic processes, regular sludge removal is necessary to prevent septic conditions and the build-up and release of gas which can hamper the sedimentation process by re-suspending part of the settled solids. Sludge transported to the surface by gas bubbles is difficult to remove and may pass to the next treatment stage.

Frequent scum removal and adequate treatment/disposal, either with the sludge or separately, is also important. Anaerobic settlers do have to be emptied less frequently as the organic material is partly transformed into gas. Accumulated slurry in the bottom of the reactor needs to be desludged every two to five years, depending on the type of the reactor (UNEP 2002, MANG 2005). For the operation and maintenance of anaerobic biogas settlers, operational requirements are very low and no professional operator is required as long as the plant is well maintained by skilled users. Starting with the seeding of some sludge from a septic tank or another anaerobic digester speeds up the digestion and prevents the digester from running acid (SASSE, 1998).

1.4.6 Anaerobic Baffled Reactor

An Anaerobic Baffled Reactor (ABR) requires a start-up period of several months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established in the reactor. To reduce start-up time, the ABR can be inoculated with anaerobic bacteria, e.g., by adding fresh cow dung or septic tank sludge. The added stock of active bacteria can then multiply and adapt to the incoming wastewater. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the ABR.

Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Process operation in general is not required, and maintenance is limited to the removal of accumulated sludge and scum every 1 to 3 years. This is best done using a motorized emptying and transport technology. The desludging frequency depends on the chosen pre-treatment steps, as well as on the design of the ABR. ABR tanks should be checked from time to time to ensure that they are watertight.

1.4.7 Anaerobic Filter

An anaerobic filter (AF) requires a start-up period of 6 to 9 months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established on the filter media. To reduce start-up time, the filter can be inoculated with anaerobic bacteria, e.g., by spraying Septic Tank sludge onto the filter material. The flow should be gradually increased over time. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the anaerobic filter. Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Over time, solids will clog the pores of the filter. As well, the growing bacterial mass will become too thick, break off and eventually clog pores. When the efficiency decreases, the filter must be cleaned. This is done by running the system in reverse mode (backwashing) or by removing and cleaning the filter material. Anaerobic filter tanks should be checked from time to time to ensure that they are watertight.

1.4.8 Up-flow Anaerobic Sludge Blanket Reactor

The Up-flow Anaerobic Sludge Blanket (UASB) is a Centralized Treatment technology that must be operated and maintained by professionals. A skilled operator is required to monitor the reactor and repair parts, e.g., pumps, in case of problems. Desludging is infrequent and only excess sludge is removed every 2 to 3 years.

1.4.9 Settling-thickening tanks

Constant monitoring and adaption accordingly are always required. In the design phase a series of assumptions are made in order to design the operation. The operation cycle consists of 1) faecal sludge loading, 2) thickened faecal sludge compaction, and 3) bottom sludge and scum removal. Pump failure is a common issue so it is important that it is installed in such a way that it can be accessed without pumping out the tank contents. Pumps should be selected based on the solids concentration of the thickened layer and available energy source. To alleviate frequent problems with pumping, solids are frequently removed by front loaders. Designing for manual removal using shovels is not recommended due to the difficult nature of removal.

The Total Suspended Solids (TSS) concentration of the supernatant will guide one in the treatment performance of the settling-thickening tank. If the TSS concentration is not suitable for the subsequent effluent treatment technology, a change in design, incoming faecal sludge, inlet/outlet design and/or more frequent desludging might be required.

1.4.10 Unplanted Sludge drying beds

Operation and maintenance to consider for unplanted sludge drying beds include:

(a) Sand and gravel must be washed prior to placing it in the filter to remove dust particles which could cause clogging of the beds,

(b) When loading it is very important not to exceed the recommended loading rates (hydraulic or solids),

(c) Faecal sludge can only be loaded onto the sludge drying beds once during each drying cycle. Partially dewatered faecal sludge forms a crust on the surface that prevents liquid from passing down to the sand layer and percolating through the drying bed,

(d) Incorrect loading can lead to ponding or clogging of beds. If clogging occurs, the entire sand and gravel layer needs to be washed or replaced,

(e) Solids removal is labour intensive, so adequate time needs to be estimated to ensure that loading cycles can be maintained,

(f) During solids removal, measures need to be taken to minimize the sand loss, as the sand layer is slowly removed, it needs to be replaced,

(g) Electrical operation and maintenance must be included if pumps are used for loading of the drying beds. Examples are spare parts and fuel,

(h) It is important to monitor the leachate as an indicator of the sludge drying bed performance (e.g. total volumes, TS concentration).

1.4.11 Planted Sludge Drying Beds

The following list presents key considerations for operation and maintenance of planted sludge drying beds:

(a) It is important to have trained operators who operate and maintain the sludge drying beds, especially during the acclimation period;

(b) During loading, make sure the faecal sludge is well distributed, especially during the start-up to ensure the filter media is not disturbed;

(c) Plant survival is crucial for treatment performance;

(d) During the start-up, the solids loading rates and feeding intervals need to be further evaluated to ensure adequate frequencies and loadings for plant health;

(e) Optimal plant densities and harvesting frequencies should be evaluated;

(f) Harvest plants by cutting them at the surface; avoid pulling them out because this will damage the root system and drying bed filter material;

(g) Monitor the drainage system and effluent for treatment performance and any possible changes;

(h) Remember that wildlife might be attracted to the plants, so fencing and measures to decrease possible vector-borne diseases might be required.

1.4.12 Co-composting

Co-composting needs to be monitored continuously in order to ensure adequate temperature and moisture content to achieve the treatment objectives. In addition, specific operational and maintenance concerns include:

(a) When turning the pile, all parts must be exposed to a high temperature in order to kill off the pathogens,

(b) The temperature is regulated by turning the pile more often if the temperature is too high. If too low, more water potentially needs to be added and/or the mass of moist input material needs to be increased,

(c) The aerobic condition in the pile is facilitated by the heap-turning frequency, which is context-dependent and needs to be determined by trial and error,

(d) Mycelium (clumps of white threads) and small insects are present to break down complex organic material and particles,

(e) Odour problems can be a sign of too high a moisture content and can be reduced by increased turning and the addition of coarse material,

(f) It may be necessary to cover co-compost piles to either protect from, or to maintain, humidity,

(g) Large amounts of flies, insects and rodents must be avoided. Covering the pile could reduce the number of flies, insects and rodents gathering,

(h) Compost as a product is sieved to separate coarse and fine compost. The coarse compost is re-used in the next round of co-composting while the fine compost is ready to be used as a soil amendment.

1.4.13 Co-treatment of Faecal Sludge with Wastewater

Implementation of co-treatment needs to be carefully monitored. Re-evaluate the treatment capacity and performance frequently to monitor for any unforeseen change in influent values. The risk of failure cannot be stressed enough, as co-treatment has been the cause of many treatment plant failures.

1.4.14 Effluent Treatment Technologies

The operation and maintenance of the effluent treatment has to be carried out by qualified staff according to the selected treatment options, for example, if the biological nature of the treatment is complex and sensitive to inflow fluctuation. If transferring or innovative technologies are selected, they need to be closely monitored so that the operation can be adapted as needed.

1.4.15 Waste Stabilization Ponds

Operation and maintenance of waste stabilization ponds The operation of the waste stabilization ponds (WSPs) includes the commissioning (starting up), maintaining and monitoring its performance.

Starting up of waste stabilization ponds Anaerobic ponds have to be filled with raw sewage and seeded with sludge from conventional sewage treatment plant or septic tank. After filling and seeding then the pond should be gradually loaded up to the design-loading rate. The pond contents should have a pH above 7 to allow the development of methanogenic bacteria. Add lime or soda ash to rise the pH in the pond if necessary. If the sewerage system is new and the flow rate as well as the loading rate to the anaerobic pond is low, then the sewage may be by-passed till the flow rate and the loading rate from the sewerage systems satisfies the condition to be discharged in the WSP. It is important to have by-pass from the anaerobic pond that will be used during desludging. It is also recommended to commission the WSPs during the beginning of the hot season so as to allow quick establishment of microorganisms of importance for the waste stabilization ponds.

The facultative WSP should be commissioned before the anaerobic WSP in order to avoid odour during the release of anaerobic pond effluent to an empty facultative WSP. During the start-up of the facultative and maturation WSPs, they should be filled with freshwater (from tap, river or wells). This will allow gradual development of algae and heterotrophic bacteria population. However, primary facultative ponds must be seeded as the anaerobic WSP. If fresh water is not available, the secondary facultative and maturation WSPs should be filled with raw sewage and leave them for three to four weeks to allow development of the microbial population.

Maintenance Maintenance for the WSPs should be carried regularly to avoid odour, flies and mosquitoes nuisance. The routine maintenance involves:

(a) Removal of screenings and grit from the inlets and outlets works,

(b) Cutting grass on the embankment and removing it so that it should not fall in the WSPs,

(c) Removing floating scum and floating macrophytes from the surface of the maturation and facultative WSPs,

(d) Spraying scum on the surface of anaerobic WSPs and should not be removed as it helps the treatment processes,

(e) Removal of any accumulated solids in the inlets and outlet works,

(f) Repair any damaged embankment as soon as possible,

(g) Repair any damage on fence and gate.

The operator must be given precise information on what to do at the WSP site. A clear form should be prepared showing the tasks to be performed by the operator that should be counter-checked by the foreman/supervisor weekly. Mara (1987) recommends that, for proper operation of the WSPs there should be a manager, assistant manager, engineers, works foreman, laboratory chemist, assistant laboratory chemist, technicians, artisan and the clerk. The number of staff depends on how extensive the project is and also on the population served as well as the degree of mechanisation aspired for.

Anaerobic WSPs requires desludging when they are one third full of the sludge by volume.

n=V/3Ps (15.1)

Where, V is the volume of the anaerobic pond (m3), P is the population served, s is the sludge accumulation rate (m3/person year) and n is the interval in years (every few years).

The value of “s” is usually 0.04 m3/person year. Sometimes the precise time to desludge the anaerobic WSP is determined by the use of the “white towel”. Mara (1987) recommends the desludging frequency to be annually. The sludge from the pond may be disposed into sludge lagoon or tankers that transport to the landfill site, agricultural land or other suitable disposal area. The disposal of sludge should be undertaken in accordance with the local regulations.

Monitoring and evaluation of the performance Frequent monitoring of the final effluent quality of a WSP system has the following importance: (a) Regular assessment as to whether the effluent is complying with the local discharge or re-use standards, (b) To detect any sudden failure or if the WSP effluent has started to deteriorate and may help to give the causes and the remedial actions to be taken.

Two levels of monitoring are recommended, Level 1 representative samples of the final effluent should be taken at least monthly or weekly and should be analysed for those parameters for which effluent discharge or re-use requirements exists. Level 2 when level 1 show that the effluent is failing to meet the standards, a more detailed study is necessary. 24-hour flow weighted composite samples are preferable for most of the parameters to be analysed, although grab samples are necessary for some (pH, temperature and faecal coliforms). The methods for collecting composite samples are as follows: (a) Automatic sampler, which takes samples every after one to two hours with subsequent manual flow weighting if this is not done automatically, (b) Taking grab samples every one to three hours with subsequent manual flow weighting, (c) Taking column sample near the outlet of the final WSP.

A full evaluation of the performance of the WSP systems can be is a time consuming and an expensive process and requires experienced personnel to interpret the results. Details on how to collect samples for evaluation of the performance of the WSP is given by Mara (1987). The evaluation of the WSP performance has the following significance: (a) Provides information on how the WSP is under loaded or overloaded, (b) Indicate how much further loading may safely be added to the system as the community increases, (c) Indicate how the future design be improved in the region.

15.5.16 Constructed Wetlands

Commissioning The commissioning of the constructed wetland involved putting substrate, filling the wetland to the level required, and planting macrophytes. Sometimes commissioning of the wetland is referred to as the time from planting to the date where the wetland is considered operational. Operation during this period should ensure an adequate cover of the wetland vegetation. Water level within the wetland during this time needs to be controlled carefully to prevent seedlings from being desiccated or drowned. Once the plants have been established, the water level may then have to be raised to operational level. Plant loss may occur during the commissioning and hence must be transplanted.

Operation The operation of the constructed wetland depends on the type of wetland and the number of preliminary treatment units used for wastewater treatment. Constructed wetlands are designed to be passive and low maintenance, not requiring continual upkeep. Constructed wetlands are however dynamic ecosystems with many variables that require managing and problem may occur when; the operator does not understand operation and maintenance, the wetland is overloaded either hydraulically or organically, unavoidable disasters such as flooding and drought, the wetland is plagued by weed problems and if excessive amount of sediments, litter and pollutants accumulate and are not removed from the wetland.

The management of the constructed wetlands consists of four tasks as shown in Table 15.2.

Table 15.2: Management of Constructed Wetland Tasks Example Operational control Varying water level and discharge