Difference between revisions of "Chapter Seventeen: Water Audit and Leakage Control"

| (One intermediate revision by the same user not shown) | |||

| Line 180: | Line 180: | ||

* Locating the leaks,<br> | * Locating the leaks,<br> | ||

* Assessment of leakage.<br> | * Assessment of leakage.<br> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Benefits of Water Audit and Leak Detection== | ==Benefits of Water Audit and Leak Detection== | ||

| Line 213: | Line 205: | ||

By protecting public property and health and providing detailed information about the distribution system, water audit and leaks detection help to protect the utility from expensive law suits. | By protecting public property and health and providing detailed information about the distribution system, water audit and leaks detection help to protect the utility from expensive law suits. | ||

</div> | </div> | ||

| + | |||

| + | |||

| + | |||

| + | Previous Page: [[Chapter Sixteen: Water Meters, Instrumentation Telemetry and Scada]] << >> Next Page: [[Chapter Eighteen: Revenue Including billing and Collection]] | ||

Latest revision as of 13:56, 20 July 2022

Contents

- 1 Chapter Seventeen: Water Audit and Leakage Control

- 1.1 Definition of Water Audit

- 1.2 Application of Water Audit

- 1.2.1 Water Audit Methodology

- 1.2.2 Planning and Preparation

- 1.2.3 Verification and Updating of Maps

- 1.2.4 Installation of Bulk Meters

- 1.2.5 Monitoring of the Production System

- 1.2.6 Transmission System

- 1.2.7 Reservoirs

- 1.2.8 Treatment Plant and Performance Monitoring

- 1.2.9 Boreholes

- 1.2.10 Monitoring of the Distribution System

- 1.2.11 Analysis

- 1.3 Leakage Control

- 1.4 Benefits of Water Audit and Leak Detection

1 Chapter Seventeen: Water Audit and Leakage Control

1.1 Definition of Water Audit

Water audit of a water supply scheme can be defined as the assessment of the capacity of total water produced by the Water Supply and Sanitation Authority (WSSA)/Community Based Water Supply Organization (CBWSO) and the actual quantity of water distributed throughout the area of service by the WSSAs/CBWSOs. Therefore, this leads to an estimation of the losses otherwise known as Non-Revenue Water (NRW) and the Un-accounted-For Water (UFW). NRW is the expression used for the difference between the quantity of water produced (or supplied) and the quantity of water billed or accounted for. The unaccounted-for water (UFW) is the part of the NRW that remains after deducting the unbilled but authorised consumption. Examples of such consumption are the water used for backwashing of filters, flushing of pipes, washing streets, firefighting, public taps and fountains, parks etc. The volume used for these purposes is usually marginal compared to the total water supplied, which makes the difference between UFW and NRW small in many systems.

Water audit in a water supply system is broadly, similar in nature to the energy audit and determines the amount of water lost from source of water to the distribution system including losses at users’ taps due to leakages and other reasons such as theft, unauthorized or illegal withdrawals from the systems and thus, these losses costs the water utility. Complete water audit plan gives a detailed profile of a water supply system including its distribution system and water users, thereby facilitating easier and effective management of the resources with improved reliability. It helps in undertaking a correct diagnosis of the problems faced and suggests optimum solutions. It is also an effective tool for realistic understanding and assessment of the system’s performance level, efficiency of the service and the adaptability of the system for future expansion & rectification of faults during modernization.

Elements of the water audit include a record of the amount of water produced, total water supplied, water delivered to metered users, water delivered to unmetered users, water losses and suggested measures to address water loss (through pinpointing & minimising leakages and other unaccounted for water losses).

Generally, the following are the recommended steps of a water audit exercise:

(a) To conduct a water audit of the water distribution system and water accounting practices etc. and validation,

(b) Preparation of worksheets and sample calculations for each step of the water audit,

(c) To identify, measure and verify all water consumption and losses,

(d) To identify and control apparent losses in metering and billing operations, and recover missed revenues,

(e) To implement a leakage and pressure management programme to control real losses, conserve water and contain costs,

(f) Develop plans to assemble the proper resources, information and equipment to launch a sustained accountability and loss-control programme,

(g) Prepare a game-plan for setting short, medium and long-term goals and estimate the returns on investment.

Leak detection programme is a tool that helps in minimizing leakages and tackling small problems before they scale-up to major ones. These programmes lead to:

(a) Reduced water losses,

(b) Improved reliability of the supply system,

(c) Enhanced knowledge of the distribution system,

(d) Efficient use of existing supplies,

(e) Better safeguards to public health and property,

(f) Improved public relations,

(g) Reduced legal liability,

(h) Reduced disruption, thereby improving levels of service to customers, and

(i) Improved financial performance.

1.2 Application of Water Audit

Application of water audit process in domestic/ municipal sector may consist of various steps including water audit, interventions for water conservation/leakages/ losses control, regulatory framework & community involvement and evaluation of effectiveness of the interventions undertaken.

1.2.1 Water Audit Methodology

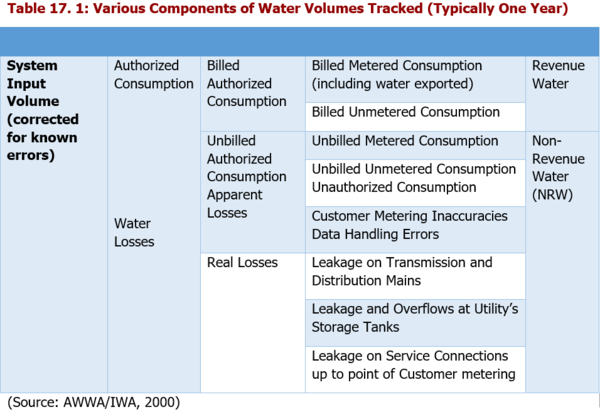

A reliable water audit methodology was developed jointly by the American Water Works Association (AWWA) and International Water Association (IWA) in the year 2000. The water balance of this methodology is given in Table 17.1 and it shows schematically, the various components in which water volumes (typically one year) are tracked.

The water balance tracks – from left to right – how a water supply agency/ utility supplies water volumes from source to customer and provides the format for the utility to quantify amounts of billed and lost water. Fundamental to the AWWA/IWA Water Audit methodology is the distinction that treated drinking water goes to two places: authorized consumption by consumers (its intended use) and a portion to losses (through inefficiencies). Within the component of losses, two broad types exist:

Apparent Losses are the “paper” losses that occur in utility operations due to customer meter inaccuracies, billing system data errors and unauthorized consumption. In other words, this is the water that is consumed but is not properly measured, accounted or paid for. These losses cost utilities revenue and distort data on customer consumption patterns.

Real Losses are the physical losses of water from the distribution system, including leakage and storage overflows. These losses inflate the water utility’s production costs and stress water resources since they represent water that is extracted and treated, yet never reaches beneficial use.

1.2.2 Planning and Preparation

Planning and preparation shall include the data collection element and the preparation of sketch plans for the distribution centres and other locations for the installation of the flow meters. Also included within this shall be the confirmation of flow rates for the bulk meter locations which has been carried out by the use of portable ultrasonic flow meters.

(a) Preliminary Data Collection

The water distribution drawings are to be studied and updated. The number of service connections is to be obtained and in the drawings of the roads, the exact locations of service connections marked. The district and sub-district boundaries are suitably fixed taking into consideration the number of service connections, length of the mains, and pressure points in the main. The exact locations of valves, hydrants with their sizes should be noted on the drawings.

The above activities will help in planning the conduct of sounding of the system for leaks or for fixing locations for conduct of pressure testing in intermittent water supply system before commencement of leak detection work or for measuring pressure and leak flow in the continuous water supply system.

(b) Pipe Location Survey

Electronic pipe locators can be used during survey. These instruments work on the principle of Electromagnetic signal propagation. It consists of a battery operated transmitter and a cordless receiver unit to pick up the signals of pre-set frequency. There are various models to choose from. Valve locators are metal detectors that are available which can be used to locate buried valves.

1.2.3 Verification and Updating of Maps

Mapping and inventory of pipes and fittings in the water supply system: If the updated maps are available and bulk meters are in position, network survey can be taken up as a first step. Otherwise maps have to be prepared and bulk meters fixed. The agency should set up routine procedures for preparing and updating maps and inventory of pipes, valves and consumer connections. The maps shall be exchanged with other public utilities and also contain information on other utility services like electricity, communications etc.

1.2.4 Installation of Bulk Meters

The major activity during the overall water audit will be bulk meter installation at those points on the distribution network where water enters the system. It is expected that bulk meters will be required at the following locations:

(a) All major system points (e.g. raw water inlet, clear water outlet, main distribution branch, SRs, etc.),

(b) Major transfer mains which are expressly required for audit,

(c) At distribution centres, the most appropriate meter position is on the outlet pipe from the service reservoir. Installation of a meter at this point will allow measurement of flows into the system not only if supplies are coming from the service reservoir but also if they are being pumped directly from the clear water reservoir (CWR),

(d) The size of the meter can be determined by flow of water, size of pipeline and meter manufacturer’s specifications having consideration of the following:

(i) Number of properties served,

(ii) Per capita consumption (litres/person/day),

(iii) Population density,

(iv) Meter manufacturer’s specifications.

Hours of supply-meter sizes must be decided according to current supply hours or size of the pipe. Future changes to the system operation may require the substitution of some bulk meters with those of a smaller size, due to reductions in flow over longer supply hours.

It is expected that bulk meters installed in locations where supply is rationed will tend to over-read. This is because when supplies are turned on, the air present in the pipes can cause the meter to spin. This problem may be overcome through the use of combined pressure and flow loggers. Flow through the meter will be recorded in the normal way. However, analysis of the pressure and flow plots together will enable the identification of that period of time when a flow is recorded at zero pressure. This time should correspond to the period when the meter is spinning, and the true flow through the meter over a period of time can therefore be calculated.

1.2.5 Monitoring of the Production System

The assessment of the leakage rates through the various features of the water supply system should be undertaken. These will include raw water transmission system, reservoirs, treatment plant, clear-water transmission system, inter-zone transmission system, boreholes/ sources of water supply. Details are provided in Chapter Seven and Nine.

1.2.6 Transmission System

The methodology adopted to make an assessment of the level of losses in the transmission system is to install insertion probes/bulk meter at both ends of each section of the main being monitored, thus monitoring both the inflow and outflow of the section. This monitoring should be done for a minimum period of 7 days. The difference of inflow and outflow will indicate the losses in the transmission main. The advantage of this method is that the trunk main need not be taken out of service.

Another way to measure leakage is to close two valves on the main. 25mm tapping are made on either side of the upstream valve and a small semi-positive displacement flow meter is connected between the two tapings. Flow through this meter will indicate the leakage in the main between the two closed valves. It must be ensured that the downstream valve is leak proof. The approximate position of any leakage measured can be determined by the successive closing of sluice valves along the main in the manner of a step test.

1.2.7 Reservoirs

To reduce or avoid any leakage or consequent contamination in reservoirs, the reservoirs should be periodically tested for water tightness, drained, cleaned, washed down and visually inspected. The losses in water storage structures can be monitored for a particular period noticing the change in the level gauges when the structure is out of use i.e. there is no inflow and outflow of water during this monitoring period.

The most reliable method for measurement of leakage from a service reservoir is to fill it to full level and isolate it from supply and to measure change in level over suitable time period. Suitable equipment to measure reservoir levels could be chosen like:

(a) Sight gauges,

(b) Water level sensors (as per manufacturer’s instruction),

(c) Float gauges,

(d) Submersible pressure & level transducers (as per manufacturer’s instruction).

1.2.8 Treatment Plant and Performance Monitoring

Performance monitoring refers to the assessment of water quality delivered from a device/process, and it requires analysis of a number of different parameters that are often dependent on the final use of the water. Users are advised to consult the relevant water quality standards or requirement on the uses of the water. The losses in a treatment plant can be monitored by measuring the inflow into the plant and outflow from the plant with the help of mechanical electronic flow recorders. The difference of inflow and outflow for the monitoring period will indicate the water losses in the plant. In case the loss is more than the design limit, further investigation should be carried out for remedial measures.

Performance monitoring refers to the assessment of water quality delivered from a device/process, and it requires analysis of a number of different parameters that are often dependent on the final use of the water. Users are advised to consultant the relevant water quality standards or requirement on the uses of the water.

1.2.9 Boreholes

In conjunction with the programme of bulk meter installation is the operation to monitor the approximate yield from the boreholes. This exercise can be carried out by the installation of semi-permanent meters to the boreholes on a bypass arrangement similar to that for the bulk meters. This can be effected by utilizing the smaller diameter bulk meters. Insertion probes or the portable ultrasonic flow meters will be used for measurement of flows on the common feeder mains.

1.2.10 Monitoring of the Distribution System

Distribution system comprises of service reservoirs, distribution mains & distribution lines. Metered, unmetered (flat rate), public stand posts, hydrants, illegal connections water audit of the distribution system consists of:

(a) Monitoring of flow of water from the distribution point into the distribution system, (b) Consumer meter sampling i.e. District Metering Area (DMA) and estimating metered use by consumers, if any, (c) Estimating losses in the appurtenances and distribution pipeline network including consumer service lines.

1.2.10.1 Monitoring Flow into the Distribution System

A bulk meter of the appropriate type and size is installed at the outlet pipe of the service reservoir or at the point where the feeding line to the area branches off from the trunk main. If water from the DMA flows out into another zone a valve or meter is to be installed at this outlet point.

Furthermore, DMAs (District Metered Areas) can be helpful in managing pressures well as NRW. At the inflow to the DMAs, pressure reducing valves can be installed, and the pressure in every DMA can be adjusted to the required level. There is no ideal size for a DMA. The size, whether it is 500 or 5,000 service connections, is always a trade-off. The decision has to be made on a case-by-case basis and depends on a number of factors (e.g., hydraulic, topographic, practical and economic).

The size of DMAs has an impact on the cost of creating them. The smaller the DMA, the higher the cost. This is because more valves and flow meters will be required and maintenance is costlier. However, the benefits of smaller DMAs are that:

- New leaks can be identified earlier, which will reduce awareness time;

- Location time can be reduced because it will be faster and easier to pinpoint the leak; and

- As a by-product, it is easier to identify illegal connections.

Topography and network layout also play an important role in DMA design and size. Therefore, there will always be DMAs of different sizes in a distribution network. An important influencing factor is the condition of the infrastructure. If mains and service connections are fragile, then bursts will be more frequent and the optimal DMA will be relatively small. On the other hand, in areas with brand new infrastructure, DMAs can be larger and still manageable.

According to the recommendations of the International Water Association’s (IWA) Water Loss Task Force, if a DMA is larger than 5,000 connections, it becomes difficult to discriminate small bursts (e.g. service connection bursts) from variations in customer night use. In networks with very poor infrastructure conditions, DMAs as small as 500 service connections might be warranted. A calibrated hydraulic model should always be used for DMA designs irrespective of the size of the DMAs.

1.2.10.2 Customer Meter Sampling

Water audit is a continuous process. However, consumers’ meter sampling can be done on a yearly basis by review of all existing bulk and major consumers for revenue. A correlation between the production/power consumed in the factory viz-a-viz water consumption can be evaluated by:

(a) Sampling of 10% of all bulk and major consumers,

(b) Sampling of 10% of small or domestic consumers,

(c) Series meter testing of large meters suitably according to standards, calibrated meters.

(d) Testing of 1% large and 1% domestic meters,

(e) Estimating consumption at a representative 5% sample of Water Points (WPs) and unmetered connections by carrying out site measurements.

All non-functioning and broken meters in the sample areas will be replaced and all meters may be read over a week. This information will be brought together with information derived from the workshop and series testing in order to estimate the average water delivered and correction factors for consumer meters. These factors can then be extrapolated to the rest of the customer meter database.

1.2.10.3 Losses in Customer Service Lines and Appurtenances

Losses can be calculated by deducting the following from the total quantity by the following:

(a) Metered consumption,

(b) Illegal connection consumption (assuming metered use),

(c) PSP use,

(d) Free supply, use in public toilets, parks etc.

1.2.11 Analysis

The information of the results of monitoring the distribution system together with the results of the bulk metering exercise will be consolidated and brought together to produce the water balance report and the overall water audit report. These results may be interpreted in financial terms. Further exercise will be done to classify the water consumed/wasted/lost in financial terms with relation to the current and future level of water charges. This exercise will be carried out as a result of the field tests and the review of existing records forming part of the overall water audit.

This water audit will provide sufficiently, accurate area wise losses to priorities the area into three (3) categories viz.

(a) Areas that need immediate leak detection and repair,

(b) Areas that need levels of losses (NRW) to be closely monitored,

(c) Areas that appear to need no further work at the current time.

It is recommended that cursory investigation should be carried out in the areas that appear to have the least levels of losses (NRW), locating any major leaks, followed by the leak repairs would reduce the losses (NRW) levels further. After water audit of few cities/ villages, it has been reported that the components of NRW may generally be as follows (GoI, 2013):

(a) Leakage (physical losses) 35 to 50%,

(b) Meter under-registration 10 to 15%,

(c) Illegal/unmetered connections 3.5 to 6%,

(d) Public use 1.5 to 3.5%.

1.3 Leakage Control

The overall objective of leakage control is to diagnose how water loss is caused and to formulate and implement action to reduce it to technically and economically acceptable minimum. Specifically the objectives are:

- To reduce losses to an acceptable minimum,

- To meet additional demands with water made available from reduced losses thereby saving in cost of additional production and distribution,

- To give consumer satisfaction,

- To augment revenue from the sale of water saved.

(a) Water Losses The water losses can be classified into two categories:

- Physical losses (Technical losses),

- Non-physical losses (Non-technical losses/Commercial losses).

(i) Physical Losses (Technical Losses) This is mainly due to leakage of water in the network and comprises of physical losses from pipes, joints & fittings, reservoirs & overflows of reservoirs & sumps.

(ii) Non-Physical Losses (Non-Technical Losses) Theft of water through illegal, already disconnected connections, under-billing either deliberately or through defective meters, water wasted by consumer through open or leaky taps, errors in estimating flat rate consumption, public stand posts and hydrants. (b) Leakage Detection and Monitoring The major activities in the leak detection work in the distribution system:

- Preliminary data collection and planning,

- Pipe location and survey,

- Assessment of pressure and flows,

- Locating the leaks,

- Assessment of leakage.

1.4 Benefits of Water Audit and Leak Detection

Water audits and leak detection programmes can achieve substantial benefits, including the following:

(a) Reduced Water Losses Water audit and leak detection are the necessary first steps in a leak repair programme. Repairing the leak will save money for the utility, including reduced power costs to deliver water and reduced chemical costs to treat water. (b) Financial Improvement A water audit and leak detection programme can increase revenues from customers who have been undercharged, lower the total cost of whole sale supplies and reduce treatment and pumping costs. (c) Increased Knowledge of the Distribution System During a water audit, distribution personnel become familiar with the distribution system, including the location of main and valves. This familiarity helps the utility to respond to emergencies such as main breaks.

(d) More Efficient Use of Existing Supplies Reducing water losses helps in stretching existing supplies to meet increased needs. This could help defer the construction of new water facilities, such as new source, reservoir or treatment plants.

(e) Safeguarding Public Health and Property Improved maintenance of a water distribution system helps to reduce the likelihood of property damage and safeguards public health and safety.

(f) Improved Public Relations The public appreciates maintenance of the water supply system. Field teams doing the water audit and leak detection or repair and maintenance work provide visual assurance that the system is being maintained. (g) Reduced Legal Liability By protecting public property and health and providing detailed information about the distribution system, water audit and leaks detection help to protect the utility from expensive law suits.

Previous Page: Chapter Sixteen: Water Meters, Instrumentation Telemetry and Scada << >> Next Page: Chapter Eighteen: Revenue Including billing and Collection