Difference between revisions of "Chapter Three: On-Site Sanitation Systems"

(Created page with "=Chapter Three: On-site Sanitation Systems= == 3.1 INTRODUCTION == Sanitation refers to the prevention of people from coming into contact with wastes generated in homes, work...") |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 19: | Line 19: | ||

which accumulates in on-site sanitation management technologies. | which accumulates in on-site sanitation management technologies. | ||

| − | ‘''Faecal Sludge (FS) is defined as the raw or partially digested, a slurry or semisolid | + | ‘''Faecal Sludge (FS) is defined as the raw or partially digested'', ''a slurry or semisolid |

| − | material resulting from the collection, storage or treatment of a combinations of | + | material resulting from the collection'', ''storage or treatment of a combinations of |

| − | excreta and black water, with or without grey water. Examples of on-site sanitation | + | excreta and black water'', ''with or without grey water''. ''Examples of on-site sanitation |

| − | technologies include pit latrines, un-sewered public ablution blocks, septic tanks, | + | technologies include pit latrines'', ''un-sewered public ablution blocks'', ''septic tanks'', |

| − | aqua privies, and dry toilets. FSM includes the storage, collection, transport, treatment | + | ''aqua privies'', ''and dry toilets''. ''FSM includes the storage'', ''collection'', ''transport'', ''treatment and safe end-use or disposal of FS''. ''FS is highly variable in consistency'', ''quantity'', ''and concentration''. |

| − | and safe end-use or disposal of FS. FS is highly variable in consistency, quantity, and | ||

| − | concentration | ||

Recently, FS has presented itself to be one of the major sanitation management | Recently, FS has presented itself to be one of the major sanitation management | ||

| Line 40: | Line 38: | ||

treatment facility is determined as depicted on Figure 3.1. | treatment facility is determined as depicted on Figure 3.1. | ||

| − | [[File:V2Figure3.1.JPG|563px|link= | + | [[File:V2Figure3.1.JPG|563px|link=Chapter_Three:_On-Site_Sanitation_Systems]] |

The complete sanitation service chain is shown in Figure 3.2. The FSM component | The complete sanitation service chain is shown in Figure 3.2. The FSM component | ||

| Line 84: | Line 82: | ||

would be too labour intensive, especially in areas where there is no existing | would be too labour intensive, especially in areas where there is no existing | ||

information. | information. | ||

| + | |||

| + | === 3.2.2 Characterization of FS === | ||

| + | The parameters that should be considered for the characterisation of FS include | ||

| + | Solids - Total Solids (TS), Total Volatile Solids (TVS) and Total Suspended Solids | ||

| + | (TSS) concentration, Chemical Oxygen Demand (COD), Biochemical Oxygen | ||

| + | Demand (BOD), Nutrients, Pathogens and metals. These parameters are the | ||

| + | same as those considered for domestic wastewater analysis. However, it needs | ||

| + | to be emphasised that the characteristics of domestic wastewater and FS are very | ||

| + | different. In the absence of the specific standards for FS analysis, the Standard | ||

| + | |||

| + | [[File:V2Figure3.3.JPG|619px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | methods for the analysis of water and wastewater as provided for by APHA, 2012 | ||

| + | should be used. | ||

| + | |||

| + | Table 3.1 presents examples from literature illustrating the high variability of | ||

| + | FS characteristics and provide a comparison with sludge from a wastewater | ||

| + | treatment plant. | ||

| + | |||

| + | The organic matter, total solids, ammonium, and helminth eggs concentrations | ||

| + | in FS are typically higher by a factor of ten or a hundred compared to wastewater | ||

| + | sludge (Montangero and Strauss, 2002).There is currently a lack of detailed | ||

| + | information on the characteristics of FS. However, research continues to | ||

| + | be actively conducted in this field. Research results, together with empirical | ||

| + | observations, will continue to increase the knowledge of FS characteristics, and | ||

| + | allow more accurate predictions of FS characteristics using less labour intensive | ||

| + | methods. | ||

| + | |||

| + | === 3.2.3 Design Considerations for Capture and Containment === | ||

| + | ==== 3.2.3.1 Pit latrines, Septic Tank-Soak-away Pit Systems ==== | ||

| + | Containment for On-site systems can be Pit Latrines of different kinds (simple or | ||

| + | traditional pit latrine, improved pit latrines, pour flush or eco-san. A pit latrines | ||

| + | can be a stand-alone or combined with a septic tank, soak-away pit. For hygiene | ||

| + | |||

| + | [[File:V2Table3.1.JPG|600px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | reasons Tanzania encourages the use of improved pit latrines while recognising | ||

| + | that many people in rural and peri-urban areas use traditional pit latrines. The | ||

| + | most common type of on-site sanitation system in urban and peri-urban areas is | ||

| + | flush toilet-septic tank-soak-away pit combination. The Ministry responsible for | ||

| + | Health has prepared guidelines for the planning and implementation of improved | ||

| + | pit latrines, septic tank and pit systems for individual households, community | ||

| + | level, institutions and for disaster situations. This document titled “MWONGOZO | ||

| + | WA UJENZI WA VYOO BORA NA USAFI WA MAZINGIRA” should be referred to for | ||

| + | guidance whenever on-site sanitation composed of any of the aforementioned | ||

| + | systems is concerned. The Ministry of Health Guidelines for Improved Latrines | ||

| + | and Environmental Sanitation should be widely disseminated and used by LGAs | ||

| + | in ensuring that the Guidelines are used. The link to the document can be found | ||

| + | at http://www.moh.go.tz/en/enviromental-health. | ||

| + | |||

| + | ==== 3.2.3.2 On-site Systems for Areas of High Water Table and Soils of Low Permeability (e.g. Clay Soils) ==== | ||

| + | Pit latrines and septic tank, soak-away pit systems described in 3.2.3.1 can be | ||

| + | implemented in areas of low water table and soils of moderate to high permeability | ||

| + | in order to allow for the necessary treatment to occur. In areas of high water | ||

| + | table, latrines and soak-away pits tend to overflow during rainy seasons and may | ||

| + | require frequent emptying which can be very expensive. There is also concern | ||

| + | over public health regarding sewage running freely in the environment. It is | ||

| + | recommended that for such areas septic tanks or latrines should be combined | ||

| + | with technologies such as constructed wetlands (CW) or subsurface drains. For | ||

| + | areas of low permeability it is recommended to use lateral subsurface drain | ||

| + | connected to the soak-away pit. | ||

| + | |||

| + | Combined Septic Tank and Constructed Wetland system | ||

| + | Figure 3.4 and Figure 3.5 show household and institutional systems of septic | ||

| + | tank-constructed wetland (CW) combination applied to an area of clay soil and | ||

| + | high water table, respectively. The design of CW is explained in section 4.2.4.4.1 | ||

| + | of this manual. | ||

| + | |||

| + | When infiltration from a soak-away pit is a problem due to low permeability of | ||

| + | the soils, increasing the area of infiltration by introducing lateral subsurface | ||

| + | drains also commonly known as French drains to the soak-away pit can be | ||

| + | applied (Figure 3.6). Subsurface drains involve excavating a trench and placing a | ||

| + | perforated pipe and coarse material such as gravel in the trench (Figure 3.7). The | ||

| + | lateral drains should follow the sloping of the land for easy draining. | ||

| + | |||

| + | [[File:V2Figure3.4.JPG|650px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | [[File:V2Figure3.5.JPG|606px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | [[File:V2Figure3.6.JPG|510px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | [[File:V2Figure3.7.JPG|648px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | === 3.2.4 Design Considerations for Emptying/Desludging === | ||

| + | Wastewater collection technologies can in general, be categorized into either | ||

| + | manually operated or mechanical collection technologies. Emptying services in | ||

| + | low and middle-income countries are frequently a mix of mechanical tools | ||

| + | and manual workforce. | ||

| + | |||

| + | ==== 3.2.4.1 Manually Operated Mechanical Emptying/Desludging ==== | ||

| + | Recent innovations in human powered mechanical devices are assisting service | ||

| + | providers in servicing septic tanks and pit latrines more quickly, safely and | ||

| + | efficiently. There are four (4) common types of mechanical pumping equipment | ||

| + | that have been developed and tried; namely, the Sludge Gulper, the diaphragm | ||

| + | pump, the Nibbler, and the Manual Pit Emptying Technology (MAPET).A designer | ||

| + | of manually operated mechanical collection is advised to refer to Table 3.2, taking | ||

| + | into consideration the characteristics of FS presented in Table 3.1. | ||

| + | |||

| + | [[File:V2Table3.2.JPG|648px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | ==== 3.2.4.2 Fully Mechanized Emptying/Desludging ==== | ||

| + | Fully mechanized technologies are powered by electricity, fuel or pneumatic | ||

| + | systems. They can be mounted on a frame or trolley for increased mobility, or | ||

| + | mounted on vehicles for emptying and transporting large quantities of sludge | ||

| + | over longer distances. A designer is guided to choose any the presented methods | ||

| + | in the Table 3.3. | ||

| + | |||

| + | [[File:V2Table3.3.JPG|533px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | [[File:V2Table3.3b.JPG|533px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | === 3.2.5 Faecal Sludge Transport Technologies === | ||

| + | There are two types of FS transport technologies, namely manual and mechanical | ||

| + | transport. The type of transport technology to be opted may be guided by a | ||

| + | number of aspects including:<br> | ||

| + | (a) the type of vehicle to be used including its road worthiness, maintenance | ||

| + | condition, licenses and permits, and where it is kept when it is not in service;<br> | ||

| + | (b) the type of sludge removal equipment, including hoses, pumps, augers, and | ||

| + | other tools of the trade;<br> | ||

| + | (c) the spill management equipment to be used including shovels, disinfectants, | ||

| + | sorbents, and collection bags;<br> | ||

| + | (d) the skills of the operator including training and certifications that might be | ||

| + | required to perform the work;<br> | ||

| + | (e) procedures that need to be followed including rules of the road and activities | ||

| + | at the treatment plant and<br> | ||

| + | (f) other aspects such as the use of transfer stations, worker’s health and safety, | ||

| + | and emerging technologies.<br> | ||

| + | |||

| + | ==== 3.2.5.1 Manual Transport ==== | ||

| + | Today, both standard carts used for general transport of materials, as well as | ||

| + | customized carts designed specifically for transport of FS, can be found in many | ||

| + | low-income countries, an example of which is shown in Figure 3.8. | ||

| + | |||

| + | [[File:V2Figure3.8.JPG|538px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | ==== 3.2.5.2 Motorized Transport ==== | ||

| + | Motorized transport equipment (Figure 3.9) offers the potential for larger load | ||

| + | capacities and increased speed, leading to reduced travel times and a greater | ||

| + | range compared to manual transport. The operation and maintenance of | ||

| + | motorized transport is generally more complex than that of manual transport. | ||

| + | However many variations are widely used in low-income countries. Before | ||

| + | selecting the type of transport system to use, it is important to verify that the | ||

| + | knowledge and skills to carry out repairs are locally available. | ||

| + | |||

| + | [[File:V2Figure3.9.JPG|541px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | === 3.2.6 Transfer Stations === | ||

| + | It has been observed that distances from the emptied OSS to a regulated | ||

| + | disposal facility of greater than 5km often result in illegal dumping of sewage | ||

| + | in creeks and rivers (Kone & Peter 2014). This illegal practice has obvious health | ||

| + | and environmental hazards resulting from contamination of water and attraction | ||

| + | of vermin and flies. In order for operators to get enough trips done in a day, | ||

| + | while keeping the service affordable, installation of FS transfer stations at a close | ||

| + | proximity to densely populated areas is essential. This approach creates a twostep | ||

| + | process for handling the waste matter (SSWM, 2014). Figure 3.10 indicates a | ||

| + | sanitation service chain of a transfer station Sanitation. | ||

| + | |||

| + | [[File:VFigure3.10.JPG|541px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | [[File:V2Figure3.11.JPG|541px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | [[File:V2Table3.4.JPG|548px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | ==== 3.2.6.1 Fixed Transfer Stations ==== | ||

| + | Fixed transfer stations can be divided into four main categories, the first of which | ||

| + | include ‘permanent storage tanks constructed as vault-like concrete structures. | ||

| + | These tanks are designed to provide storage capacity for FS over a short period | ||

| + | of time when there is no capacity for treatment. An example of such tanks are the | ||

| + | underground holding tank (UHT) reported by Boot (2007) in Accra, Ghana. With | ||

| + | capacities of approximately 23 m3, the UHTs were designed to provide access | ||

| + | to pan latrine collectors (primary transport) and vacuum trucks (secondary | ||

| + | transport). Care must be taken to ensure that FS is NOT stored over long periods | ||

| + | as it may cause transport operational challenges due to settling of sludge. | ||

| + | |||

| + | The fixed transfer station essentially serves the role of a secure, safe, storage | ||

| + | facility and can be designed according to the type of containers used. For example, | ||

| + | in one project in Ghana a concrete-lined pit within a fenced compound was used | ||

| + | to store the containers in order to avoid tampering, flooding or spillage. Once full | ||

| + | the IBCs are emptied with a vacuum truck. Figure 3.12 presents an example of a | ||

| + | fixed transfer station showing the top of an underground holding tank, a chain | ||

| + | to lock the lid, a vent pipe and a wall to prevent overflowing of excreta travelling | ||

| + | onto the road. | ||

| + | |||

| + | [[File:V2Figure3.12.JPG|488px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | ==== 3.2.6.2 Mobile Transfer Stations ==== | ||

| + | Mobile transfer stations consist of easily transportable containers providing | ||

| + | temporary storage capacity at any point near the structure being emptiedessentially | ||

| + | a tank fitted on a wheeled chassis. Examples of such transfer stations | ||

| + | include motorised collection vehicles, or tanker trailers pulled via a truck or tractor. | ||

| + | Figure 3.13indicates a schematic presentation of a typical mobile transfer station. | ||

| + | |||

| + | [[File:V2Figure3.13.JPG|524px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | === 3.2.7 Design Procedures for Faecal Sludge Treatment === | ||

| + | The engineering design approach provides a systematic way of setting appropriate | ||

| + | treatment objectives in the absence of a clear regulatory framework. The three | ||

| + | steps of the engineering design approach for FST plants that are briefly introduced | ||

| + | in this chapter are: | ||

| + | * Setting treatment objectives based on the final end-use or disposal option, | ||

| + | * Estimating quantities and qualities (Q&Q) of incoming FS, | ||

| + | * Evaluating selection of management solutions and treatment technologies. | ||

| + | |||

| + | The engineering design approach is an iterative process that needs to take into | ||

| + | account the dynamics of the full FSM chain and an enabling environment. | ||

| + | |||

| + | '''Step 1'''<br> | ||

| + | First, options for the final end-use or disposal of treated FS should be evaluated. | ||

| + | Based on the end-use, treatment objectives and corresponding performance goals | ||

| + | have to be defined such as can be used to work backwards and to inform design | ||

| + | variables for the treatment technology that can achieve these goals. Examples are | ||

| + | pathogen inactivation for a certain treatment product and an acceptable level of | ||

| + | pathogen reduction that can be measured to ensure the treatment objective. It is | ||

| + | important to keep in mind that over-designing treatment systems wastes money | ||

| + | and resources, while under-designing does not provide adequate protection of | ||

| + | human and environmental health. | ||

| + | |||

| + | '''Step 2''' | ||

| + | Second is developing an understanding of the FS quantity and quality (Q&Q) that | ||

| + | will be arriving at the treatment facility. Based on these estimates, technologies | ||

| + | can be selected and sized appropriately. For more information on methods to | ||

| + | determine Q&Q of FS at community to city-wide scales relevant for the design of | ||

| + | treatment and management solution the designer is referred to latest research | ||

| + | findings from the area or similar neighbourhood. | ||

| + | |||

| + | '''Step 3'''<br> | ||

| + | Based on the defined treatment objectives and the estimated incoming Q&Q | ||

| + | of FS, appropriate and feasible technology and management options can be | ||

| + | selected. To select the most appropriate options, the following factors will have | ||

| + | to be considered;<br> | ||

| + | |||

| + | (a) existing infrastructure and services,<br> | ||

| + | (b) available skills and capacities,<br> | ||

| + | (c) legal requirements and regulations,<br> | ||

| + | (d) social acceptance and norms,<br> | ||

| + | (e) operation and maintenance and<br> | ||

| + | (f) financial viability.<br> | ||

| + | |||

| + | Various trade-offs exist among all these factors. It is important to find an | ||

| + | acceptable balance from all stakeholders. | ||

| + | |||

| + | When selecting an appropriate technology for FST, it is very important to consider | ||

| + | whether technologies are established, being transferred from other sectors, or | ||

| + | are still at the innovation phase of development. Technologies are classified | ||

| + | based on | ||

| + | (a) the level of adaption,<br> | ||

| + | (b) research,<br> | ||

| + | (c) innovation and<br> | ||

| + | (d) expert knowledge that is required for successful implementation.<br> | ||

| + | |||

| + | Technologies are considered established if their design and operational and | ||

| + | maintenance guidelines can be readily recommended. Transferring technologies | ||

| + | is still in the process of being adapted for FSM from other sectors such as | ||

| + | wastewater treatment or solid waste management. Innovative technologies are | ||

| + | promising and potentially ready to be scaled up, but are currently still at the pilot | ||

| + | stage of development. | ||

| + | |||

| + | Table 3.5 summarizes FST technologies and their level of development. The | ||

| + | implementation of transferring and innovative technologies has an increased | ||

| + | risk due to there being no or less operating experience. Hence, technology | ||

| + | development needs to be managed during every operation. This could be | ||

| + | done through, for example, public or public-private partnerships or research | ||

| + | collaboration with research entities or universities. | ||

| + | |||

| + | The first step in the engineering design approach is defining the treatment | ||

| + | objectives based on the effluent and treated sludge required standards, resource | ||

| + | recovery and/or disposal options. Selecting technologies is also based on factors | ||

| + | such as cost, operational and maintenance requirements, and FS quantities and | ||

| + | qualities (Q&Q) that need to be treated. | ||

| + | |||

| + | [[File:V2Table3.5.JPG|524px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | Figure 3.14 presents an example of a treatment plant process flow sheet, and the | ||

| + | treatment objectives achieved with each technology. | ||

| + | |||

| + | [[File:V2Figure3.14.JPG|722px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | The treatment process includes screening to remove solid waste, Anaerobic | ||

| + | Stabilization Reactor (ASR) for stabilization, unplanted sludge drying beds for | ||

| + | dewatering. The dewatered solids from the unplanted drying beds are either | ||

| + | co-composted or thermally dried in a solar heated greenhouse to inactivate | ||

| + | pathogens prior end-use. The liquid stream from dewatering unit is treated by | ||

| + | Anaerobic Baffled Reactor (ABR), Anaerobic Filter (AF), Planted Gravel Filter (PGF), | ||

| + | Pressure Sand and Activated Carbon Filter (PS &ACF) and finally disinfected in | ||

| + | polishing ponds (PP). Figure 3.15 indicates FS Treatment Plant (FSTP) flow sheet | ||

| + | as proposed by CDD society. | ||

| + | |||

| + | [[File:V2Figure3.15.JPG|722px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | ==== 3.2.7.1 Settling-thickening Tanks ==== | ||

| + | The main treatment objective of settling-thickening tanks is solid-liquid separation. | ||

| + | Pathogen inactivation does not occur, and both liquid effluent and settled sludge | ||

| + | require further treatment. Thickened sludge is normally removed after 5 to 30 | ||

| + | days by a combination of pumps, front-loaders, and/or manually with shovels. | ||

| + | The loading period should be adjusted with the TSS in the supernatant layer. If | ||

| + | the outlet’s TSS concentration is too high, adjustments are required. There are | ||

| + | normally two parallel tanks to allow for sludge removal and maintenance. | ||

| + | Settling-thickening tanks have an inlet with a baffle to ensure quiescent flow, and | ||

| + | an outlet with a baffle to allow only the supernatant to pass through the outlet. | ||

| + | Figure 3.16 presents a schematic sketch of a typical settling-thickening tank. The | ||

| + | floor is commonly either sloped so sludge can be pumped out, or else flat with | ||

| + | access for removal by a front loader. Total suspended solids settle out into the | ||

| + | thickened layer, and fats, oils and grease float in the scum layer. | ||

| + | |||

| + | [[File:V2Figure3.16.JPG|669px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | Prior to designing a settling-thickening tank, tests should be conducted with | ||

| + | Imhoff cones to determine the settleability of the specific sludge. Settleability | ||

| + | (recommended to be <100 mL/g TSS for settling) is determined by the Sludge | ||

| + | Volume Index (SVI) and is estimated by settling of 1 litre of FS in Imhoff cones or | ||

| + | columns for 30 to 60 minutes. The SVI is then calculated from the volume that | ||

| + | settles at the bottom of these Imhoff cones divided by the initial total suspended | ||

| + | solids concentration, CTSS. | ||

| + | |||

| + | [[File:V2Fomula3.1.JPG|693px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | In general, it has been observed that sludge that is more stable, settles better | ||

| + | than sludge that has been stored in the containment for shorter periods of time. | ||

| + | Treatment performance can be measured by TSS concentrations in the effluent/ | ||

| + | supernatant. | ||

| + | |||

| + | '''Sizing settling-thickening tanks'''<br> | ||

| + | The approach taken for the sizing of settling-thickening tanks is summarized in | ||

| + | Table 3.6. | ||

| + | |||

| + | [[File:V2Table3.6.JPG|727px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | '''Step 1: Establish design criteria'''<br> | ||

| + | The design of settling-thickening tanks is based on the TSS concentration of the | ||

| + | incoming sludge and its settleability. FS can either be discharged directly to the | ||

| + | settling thickening tanks, in which case following the Q&Q method to determine | ||

| + | quantities and qualities and quantities would be most appropriate, or can be | ||

| + | loaded using other technologies. The following parameters are important: | ||

| + | |||

| + | [[File:V2Fomula.JPG|720px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | '''Step 2: Calculate surface area'''<br> | ||

| + | The surface area is calculated based on the peak flow to ensure enough time for | ||

| + | the particles to settle. | ||

| + | |||

| + | [[File:V2Fomula3.3.JPG|706px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | Based on existing experience, the settling velocity can be estimated as 0.5 m/h in | ||

| + | rectangular settling-thickening tanks to treat FS with a SVI of less than 100 mL/g | ||

| + | TSS. The tank is designed based on the desired removal of particles from the | ||

| + | supernatant to the solids layer. In order for the particles to settle in the tank, a | ||

| + | settling velocity greater than the inflow velocity is required, as shown in Figure | ||

| + | 3.17. The recommended ratio between width and length is between 1:10 and 1:5. | ||

| + | Lower settling velocities require longer tanks for particles to settle and remain in | ||

| + | the tank. Depending on the planned operation of the tank, the design will vary. | ||

| + | Manual emptying, either by truck or pump, of solids will result in different layouts | ||

| + | and loading and discharge cycles. The calculated area should be doubled so that | ||

| + | two parallel-operated settling-thickening tanks can receive discharged FS. | ||

| + | |||

| + | [[File:V2Figure3.17.JPG|706px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | '''Step 3: Sizing of thickened sludge layer'''<br> | ||

| + | The thickened sludge layer depth will vary with TSS concentration and will govern | ||

| + | the design of the settling-thickening tank. | ||

| + | |||

| + | [[File:V2Fomula3.4.5.JPG|698px|link=Chapter_Three:_On-Site_Sanitation_Systems]] | ||

| + | |||

| + | Vt: Volume of thickened sludge storage zone (m3)<br> | ||

| + | Qs: Daily inflow of FS to the settling-thickening tank (m3/d)<br> | ||

| + | CTSS,in: TSS concentration of incoming FS (kg TSS/m3)<br> | ||

| + | CTSS,out: TSS concentration of thickened FS (kg TSS/m3)<br> | ||

| + | e: Settling efficiency<br> | ||

| + | N: FS loading time (d)<br> | ||

| + | dt: Thickened FS depth (m)<br> | ||

| + | |||

| + | To find out how much sludge has accumulated in the thickened sludge layer, | ||

| + | the average daily inflow is used. However, in reality the FS loading period (N) is | ||

| + | also determined by a trade off or consideration of the treatment technologies | ||

| + | that then follow, although it should not exceed four weeks. As a principle, the | ||

| + | more time the thickened FS has to compact, the more challenging the removal | ||

| + | with pumps will be. Expected TSS concentrations in the solids and supernatant | ||

| + | layers can be estimated by using Imhoff cones or column testing prior to | ||

| + | designing the system. | ||

| + | |||

| + | '''Step 4: Determine tank depth'''<br> | ||

| + | The total depth is established by assumptions of the scum, supernatant and | ||

| + | separation layer depth. Nevertheless, excavation costs for building tanks are | ||

| + | commonly high and are a limiting factor in the maximum depth. Preliminary | ||

| + | guidelines based on studies in Accra are presented in Table 3.7. | ||

| + | |||

| + | </div> | ||

| + | |||

| + | Previous Page: [[Chapter_Two:_Planning_for_Sanitation_Projects|Chapter_Two:_Planning_for_Sanitation_Projects]] << >> Next Page: [[Chapter_Four:_Off-Site_Sanitation_Systems]] | ||

Latest revision as of 06:10, 21 July 2022

Contents

- 1 Chapter Three: On-site Sanitation Systems

- 1.1 3.1 INTRODUCTION

- 1.2 3.2 FAECAL SLUDGE MANAGEMENT (FSM)

- 1.2.1 3.2.1 Quantification of FS

- 1.2.2 3.2.2 Characterization of FS

- 1.2.3 3.2.3 Design Considerations for Capture and Containment

- 1.2.4 3.2.4 Design Considerations for Emptying/Desludging

- 1.2.5 3.2.5 Faecal Sludge Transport Technologies

- 1.2.6 3.2.6 Transfer Stations

- 1.2.7 3.2.7 Design Procedures for Faecal Sludge Treatment

1 Chapter Three: On-site Sanitation Systems

1.1 3.1 INTRODUCTION

Sanitation refers to the prevention of people from coming into contact with wastes generated in homes, workplaces and public buildings, by providing facilities and services for the safe management of human excreta to containment and storage and treatment on-site or conveyance, treatment and eventual safe end use or disposal (https://www.who.int/topics/sanitation/en/). On the basis of the transport and treatment mode, there are two main types of sanitation systems, namely; on-site sanitation (OSS) and off-site sanitation systems. Under the off-site system, there are two sub-categories of centralized and Decentralized Wastewater Treatment (DEWAT). This manual provides guidance for the design of both types of systems. This chapter focuses on OSS.

1.2 3.2 FAECAL SLUDGE MANAGEMENT (FSM)

In Tanzania, it is estimated that about 90% of the population is served by OSS and technologies which include pit latrines, septic tanks and soak-away pits (Brande et al, 2015). These systems end up generating huge volumes of faecal sludge (FS) which accumulates in on-site sanitation management technologies.

‘Faecal Sludge (FS) is defined as the raw or partially digested, a slurry or semisolid material resulting from the collection, storage or treatment of a combinations of excreta and black water, with or without grey water. Examples of on-site sanitation technologies include pit latrines, un-sewered public ablution blocks, septic tanks, aqua privies, and dry toilets. FSM includes the storage, collection, transport, treatment and safe end-use or disposal of FS. FS is highly variable in consistency, quantity, and concentration.

Recently, FS has presented itself to be one of the major sanitation management challenges in urban areas of Tanzania. This calls for adequate and appropriate FSM.

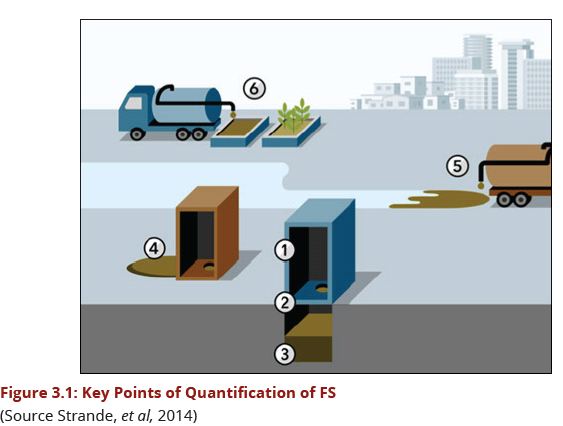

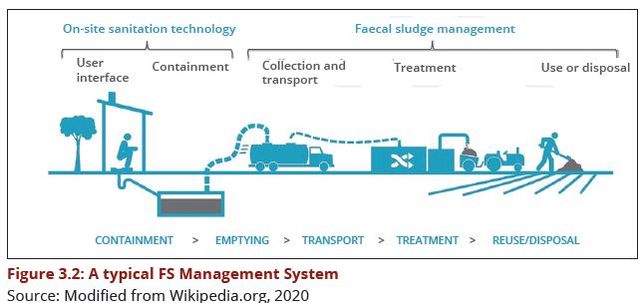

To better address FSM challenges, it is important to consider FSM as a sanitation service delivery chain. In a developing country settings FSM refers to organized programmes that provide safe and hygienic septic tank and pit latrine emptying services, along with the proper treatment of liquids and re-use of related bio-solids where possible. Adequate and proper FSM follows a ‘service chain’ approach. The service chain includes the collection, storage, transport, treatment and safe enduse or disposal of FS. FS quantity which is an important element in design of FS treatment facility is determined as depicted on Figure 3.1.

The complete sanitation service chain is shown in Figure 3.2. The FSM component is specifically the emptying, collection, transport, treatment and end-use or disposal of FS. This design manual provides a framework for the design of sanitation systems in all its components of sanitation service delivery chain.

1.2.1 3.2.1 Quantification of FS

Deriving accurate estimates for the volume of FS produced in an area is essential for the proper sizing of infrastructure required for the relevant collection and transport networks, discharge sites, treatment plants, and end-use or disposal options. The first step in designing FS (FS) treatment technologies that will meet defined treatment objectives. This will quantify and characterise the FS to be treated. Ideally, this should be carried out as part of the feasibility study.

Accurate estimate of FS volume is crucial for the appropriate sizing of collection

and transport systems, treatment facilities, discharging sites and disposal

options. While methods for quantification of FS are still being evaluated globally,

the following key points have been applied in the quantification of FS:

(a) The amount of excreta going into the toilet depending on how many people

eat and excrete in a location,

(b) How much FS is produced in addition to toilet paper and flush water to the

previous number,

(c) The amount of FS accumulated by balancing accumulation and degradation

(currently it is done empirically),

(d) The amount emptied from the containment,

(e) The amount that is illegally discharged,

(f) The actual amount delivered to the treatment plant

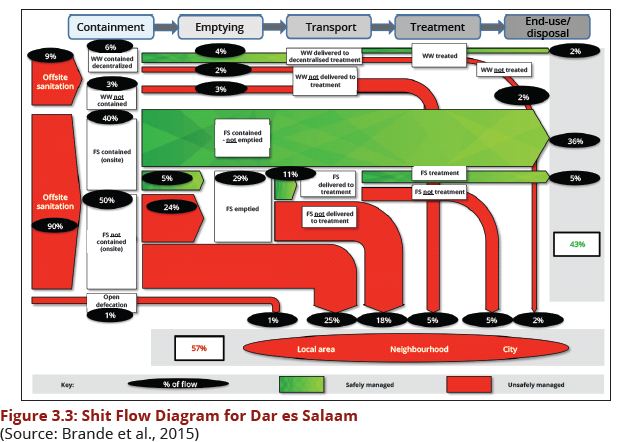

Additionally, Figure 3.1 should be used together with the shit flow diagram

presented in Figure 3.3 to estimate the quantity of FS.

Due to the variability of FS volumes generated, it is important to make estimates based on the requirements specifically for each location and not to estimate values based on literature. For example, from the FS quantification diagram, bullet six will be obtained from the number of trucks and their capacity. Then from the shit flow diagram, this amount is equal to 11%. So, the total quantity of FS generated is (quantity at point 6/0.11).

However, no proven methods exist for quantifying the production of FS in urban areas, and the data collection required in order to accurately quantify FS volumes would be too labour intensive, especially in areas where there is no existing information.

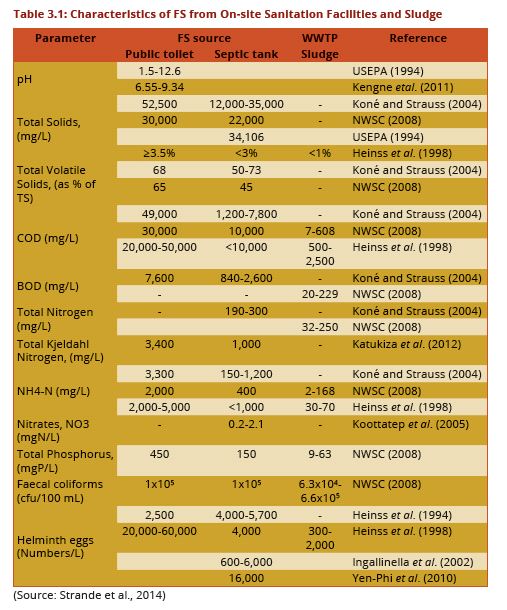

1.2.2 3.2.2 Characterization of FS

The parameters that should be considered for the characterisation of FS include Solids - Total Solids (TS), Total Volatile Solids (TVS) and Total Suspended Solids (TSS) concentration, Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), Nutrients, Pathogens and metals. These parameters are the same as those considered for domestic wastewater analysis. However, it needs to be emphasised that the characteristics of domestic wastewater and FS are very different. In the absence of the specific standards for FS analysis, the Standard

methods for the analysis of water and wastewater as provided for by APHA, 2012 should be used.

Table 3.1 presents examples from literature illustrating the high variability of FS characteristics and provide a comparison with sludge from a wastewater treatment plant.

The organic matter, total solids, ammonium, and helminth eggs concentrations in FS are typically higher by a factor of ten or a hundred compared to wastewater sludge (Montangero and Strauss, 2002).There is currently a lack of detailed information on the characteristics of FS. However, research continues to be actively conducted in this field. Research results, together with empirical observations, will continue to increase the knowledge of FS characteristics, and allow more accurate predictions of FS characteristics using less labour intensive methods.

1.2.3 3.2.3 Design Considerations for Capture and Containment

1.2.3.1 3.2.3.1 Pit latrines, Septic Tank-Soak-away Pit Systems

Containment for On-site systems can be Pit Latrines of different kinds (simple or traditional pit latrine, improved pit latrines, pour flush or eco-san. A pit latrines can be a stand-alone or combined with a septic tank, soak-away pit. For hygiene

reasons Tanzania encourages the use of improved pit latrines while recognising that many people in rural and peri-urban areas use traditional pit latrines. The most common type of on-site sanitation system in urban and peri-urban areas is flush toilet-septic tank-soak-away pit combination. The Ministry responsible for Health has prepared guidelines for the planning and implementation of improved pit latrines, septic tank and pit systems for individual households, community level, institutions and for disaster situations. This document titled “MWONGOZO WA UJENZI WA VYOO BORA NA USAFI WA MAZINGIRA” should be referred to for guidance whenever on-site sanitation composed of any of the aforementioned systems is concerned. The Ministry of Health Guidelines for Improved Latrines and Environmental Sanitation should be widely disseminated and used by LGAs in ensuring that the Guidelines are used. The link to the document can be found at http://www.moh.go.tz/en/enviromental-health.

1.2.3.2 3.2.3.2 On-site Systems for Areas of High Water Table and Soils of Low Permeability (e.g. Clay Soils)

Pit latrines and septic tank, soak-away pit systems described in 3.2.3.1 can be implemented in areas of low water table and soils of moderate to high permeability in order to allow for the necessary treatment to occur. In areas of high water table, latrines and soak-away pits tend to overflow during rainy seasons and may require frequent emptying which can be very expensive. There is also concern over public health regarding sewage running freely in the environment. It is recommended that for such areas septic tanks or latrines should be combined with technologies such as constructed wetlands (CW) or subsurface drains. For areas of low permeability it is recommended to use lateral subsurface drain connected to the soak-away pit.

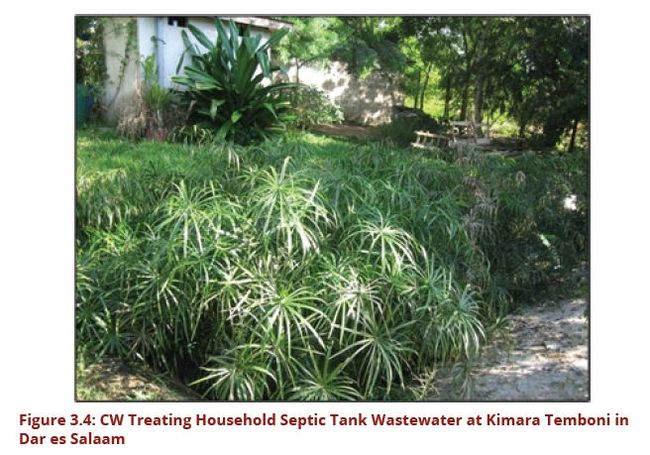

Combined Septic Tank and Constructed Wetland system Figure 3.4 and Figure 3.5 show household and institutional systems of septic tank-constructed wetland (CW) combination applied to an area of clay soil and high water table, respectively. The design of CW is explained in section 4.2.4.4.1 of this manual.

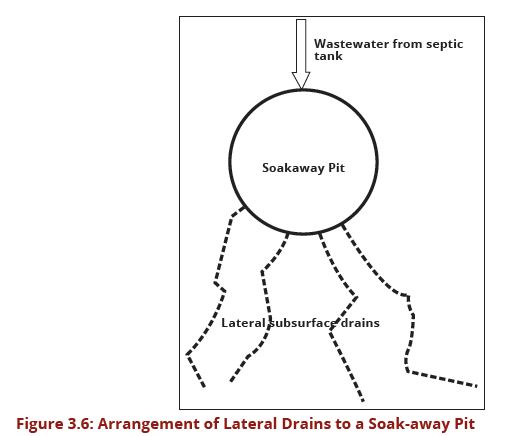

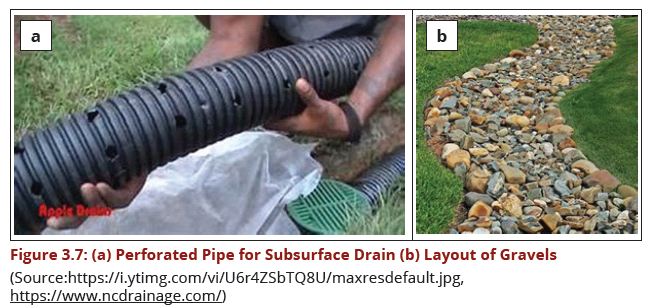

When infiltration from a soak-away pit is a problem due to low permeability of the soils, increasing the area of infiltration by introducing lateral subsurface drains also commonly known as French drains to the soak-away pit can be applied (Figure 3.6). Subsurface drains involve excavating a trench and placing a perforated pipe and coarse material such as gravel in the trench (Figure 3.7). The lateral drains should follow the sloping of the land for easy draining.

1.2.4 3.2.4 Design Considerations for Emptying/Desludging

Wastewater collection technologies can in general, be categorized into either manually operated or mechanical collection technologies. Emptying services in low and middle-income countries are frequently a mix of mechanical tools and manual workforce.

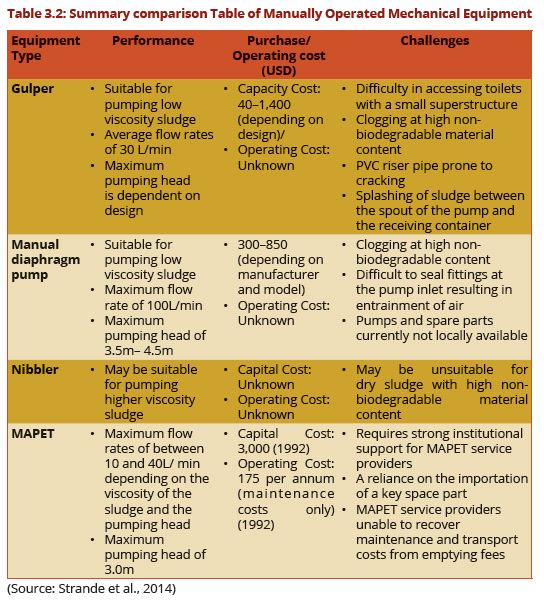

1.2.4.1 3.2.4.1 Manually Operated Mechanical Emptying/Desludging

Recent innovations in human powered mechanical devices are assisting service providers in servicing septic tanks and pit latrines more quickly, safely and efficiently. There are four (4) common types of mechanical pumping equipment that have been developed and tried; namely, the Sludge Gulper, the diaphragm pump, the Nibbler, and the Manual Pit Emptying Technology (MAPET).A designer of manually operated mechanical collection is advised to refer to Table 3.2, taking into consideration the characteristics of FS presented in Table 3.1.

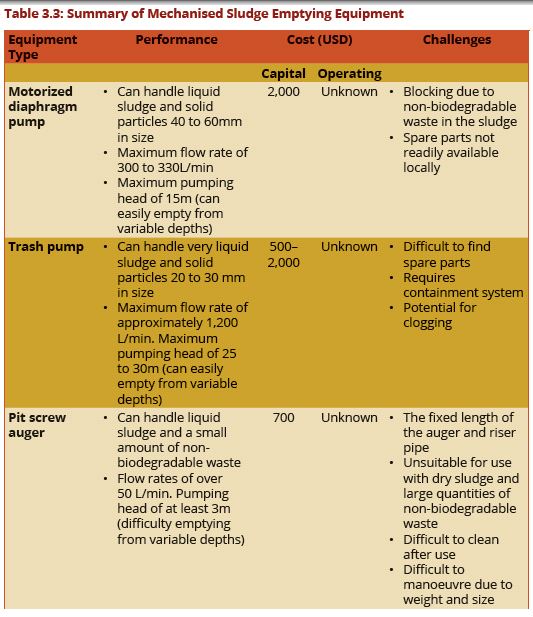

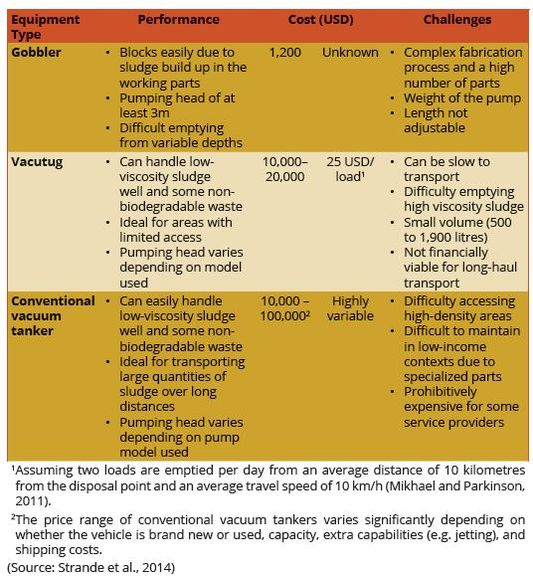

1.2.4.2 3.2.4.2 Fully Mechanized Emptying/Desludging

Fully mechanized technologies are powered by electricity, fuel or pneumatic systems. They can be mounted on a frame or trolley for increased mobility, or mounted on vehicles for emptying and transporting large quantities of sludge over longer distances. A designer is guided to choose any the presented methods in the Table 3.3.

1.2.5 3.2.5 Faecal Sludge Transport Technologies

There are two types of FS transport technologies, namely manual and mechanical

transport. The type of transport technology to be opted may be guided by a

number of aspects including:

(a) the type of vehicle to be used including its road worthiness, maintenance

condition, licenses and permits, and where it is kept when it is not in service;

(b) the type of sludge removal equipment, including hoses, pumps, augers, and

other tools of the trade;

(c) the spill management equipment to be used including shovels, disinfectants,

sorbents, and collection bags;

(d) the skills of the operator including training and certifications that might be

required to perform the work;

(e) procedures that need to be followed including rules of the road and activities

at the treatment plant and

(f) other aspects such as the use of transfer stations, worker’s health and safety,

and emerging technologies.

1.2.5.1 3.2.5.1 Manual Transport

Today, both standard carts used for general transport of materials, as well as customized carts designed specifically for transport of FS, can be found in many low-income countries, an example of which is shown in Figure 3.8.

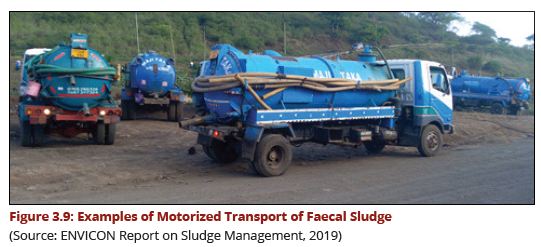

1.2.5.2 3.2.5.2 Motorized Transport

Motorized transport equipment (Figure 3.9) offers the potential for larger load capacities and increased speed, leading to reduced travel times and a greater range compared to manual transport. The operation and maintenance of motorized transport is generally more complex than that of manual transport. However many variations are widely used in low-income countries. Before selecting the type of transport system to use, it is important to verify that the knowledge and skills to carry out repairs are locally available.

1.2.6 3.2.6 Transfer Stations

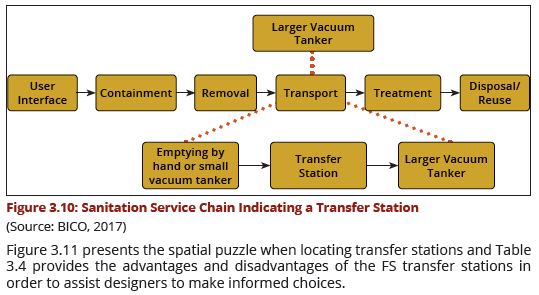

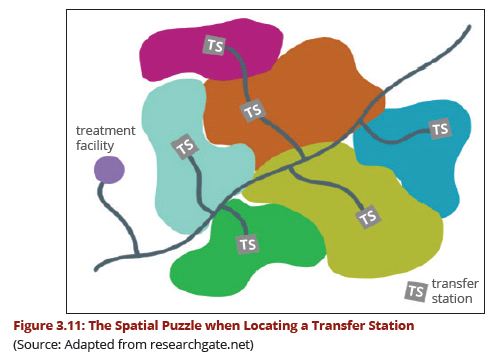

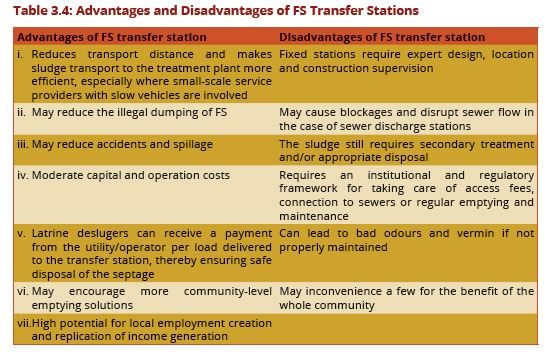

It has been observed that distances from the emptied OSS to a regulated disposal facility of greater than 5km often result in illegal dumping of sewage in creeks and rivers (Kone & Peter 2014). This illegal practice has obvious health and environmental hazards resulting from contamination of water and attraction of vermin and flies. In order for operators to get enough trips done in a day, while keeping the service affordable, installation of FS transfer stations at a close proximity to densely populated areas is essential. This approach creates a twostep process for handling the waste matter (SSWM, 2014). Figure 3.10 indicates a sanitation service chain of a transfer station Sanitation.

1.2.6.1 3.2.6.1 Fixed Transfer Stations

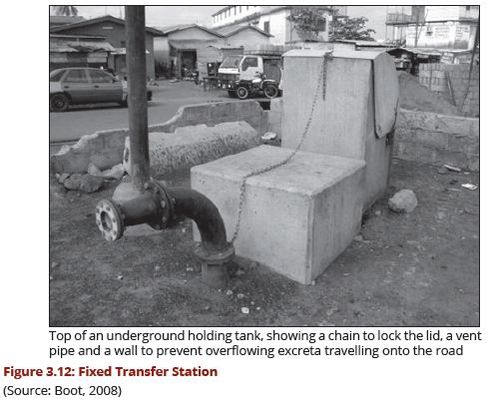

Fixed transfer stations can be divided into four main categories, the first of which include ‘permanent storage tanks constructed as vault-like concrete structures. These tanks are designed to provide storage capacity for FS over a short period of time when there is no capacity for treatment. An example of such tanks are the underground holding tank (UHT) reported by Boot (2007) in Accra, Ghana. With capacities of approximately 23 m3, the UHTs were designed to provide access to pan latrine collectors (primary transport) and vacuum trucks (secondary transport). Care must be taken to ensure that FS is NOT stored over long periods as it may cause transport operational challenges due to settling of sludge.

The fixed transfer station essentially serves the role of a secure, safe, storage facility and can be designed according to the type of containers used. For example, in one project in Ghana a concrete-lined pit within a fenced compound was used to store the containers in order to avoid tampering, flooding or spillage. Once full the IBCs are emptied with a vacuum truck. Figure 3.12 presents an example of a fixed transfer station showing the top of an underground holding tank, a chain to lock the lid, a vent pipe and a wall to prevent overflowing of excreta travelling onto the road.

1.2.6.2 3.2.6.2 Mobile Transfer Stations

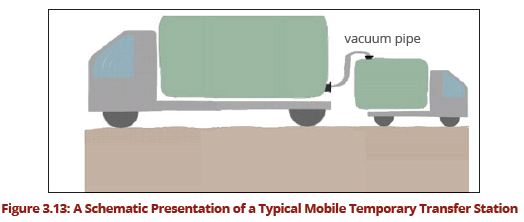

Mobile transfer stations consist of easily transportable containers providing temporary storage capacity at any point near the structure being emptiedessentially a tank fitted on a wheeled chassis. Examples of such transfer stations include motorised collection vehicles, or tanker trailers pulled via a truck or tractor. Figure 3.13indicates a schematic presentation of a typical mobile transfer station.

1.2.7 3.2.7 Design Procedures for Faecal Sludge Treatment

The engineering design approach provides a systematic way of setting appropriate treatment objectives in the absence of a clear regulatory framework. The three steps of the engineering design approach for FST plants that are briefly introduced in this chapter are:

- Setting treatment objectives based on the final end-use or disposal option,

- Estimating quantities and qualities (Q&Q) of incoming FS,

- Evaluating selection of management solutions and treatment technologies.

The engineering design approach is an iterative process that needs to take into account the dynamics of the full FSM chain and an enabling environment.

Step 1

First, options for the final end-use or disposal of treated FS should be evaluated.

Based on the end-use, treatment objectives and corresponding performance goals

have to be defined such as can be used to work backwards and to inform design

variables for the treatment technology that can achieve these goals. Examples are

pathogen inactivation for a certain treatment product and an acceptable level of

pathogen reduction that can be measured to ensure the treatment objective. It is

important to keep in mind that over-designing treatment systems wastes money

and resources, while under-designing does not provide adequate protection of

human and environmental health.

Step 2 Second is developing an understanding of the FS quantity and quality (Q&Q) that will be arriving at the treatment facility. Based on these estimates, technologies can be selected and sized appropriately. For more information on methods to determine Q&Q of FS at community to city-wide scales relevant for the design of treatment and management solution the designer is referred to latest research findings from the area or similar neighbourhood.

Step 3

Based on the defined treatment objectives and the estimated incoming Q&Q

of FS, appropriate and feasible technology and management options can be

selected. To select the most appropriate options, the following factors will have

to be considered;

(a) existing infrastructure and services,

(b) available skills and capacities,

(c) legal requirements and regulations,

(d) social acceptance and norms,

(e) operation and maintenance and

(f) financial viability.

Various trade-offs exist among all these factors. It is important to find an acceptable balance from all stakeholders.

When selecting an appropriate technology for FST, it is very important to consider

whether technologies are established, being transferred from other sectors, or

are still at the innovation phase of development. Technologies are classified

based on

(a) the level of adaption,

(b) research,

(c) innovation and

(d) expert knowledge that is required for successful implementation.

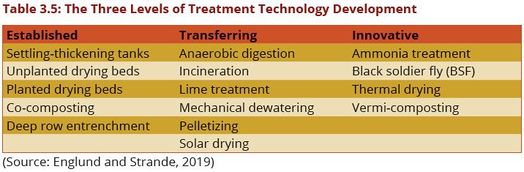

Technologies are considered established if their design and operational and maintenance guidelines can be readily recommended. Transferring technologies is still in the process of being adapted for FSM from other sectors such as wastewater treatment or solid waste management. Innovative technologies are promising and potentially ready to be scaled up, but are currently still at the pilot stage of development.

Table 3.5 summarizes FST technologies and their level of development. The implementation of transferring and innovative technologies has an increased risk due to there being no or less operating experience. Hence, technology development needs to be managed during every operation. This could be done through, for example, public or public-private partnerships or research collaboration with research entities or universities.

The first step in the engineering design approach is defining the treatment objectives based on the effluent and treated sludge required standards, resource recovery and/or disposal options. Selecting technologies is also based on factors such as cost, operational and maintenance requirements, and FS quantities and qualities (Q&Q) that need to be treated.

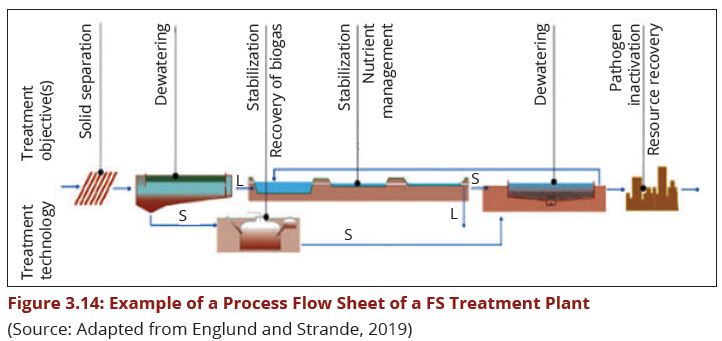

Figure 3.14 presents an example of a treatment plant process flow sheet, and the treatment objectives achieved with each technology.

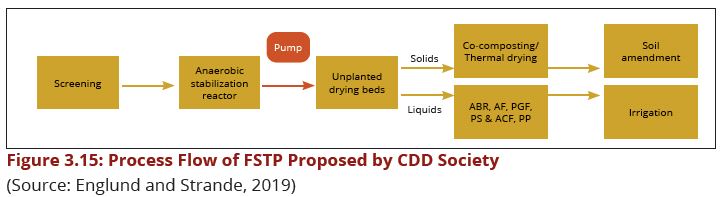

The treatment process includes screening to remove solid waste, Anaerobic Stabilization Reactor (ASR) for stabilization, unplanted sludge drying beds for dewatering. The dewatered solids from the unplanted drying beds are either co-composted or thermally dried in a solar heated greenhouse to inactivate pathogens prior end-use. The liquid stream from dewatering unit is treated by Anaerobic Baffled Reactor (ABR), Anaerobic Filter (AF), Planted Gravel Filter (PGF), Pressure Sand and Activated Carbon Filter (PS &ACF) and finally disinfected in polishing ponds (PP). Figure 3.15 indicates FS Treatment Plant (FSTP) flow sheet as proposed by CDD society.

1.2.7.1 3.2.7.1 Settling-thickening Tanks

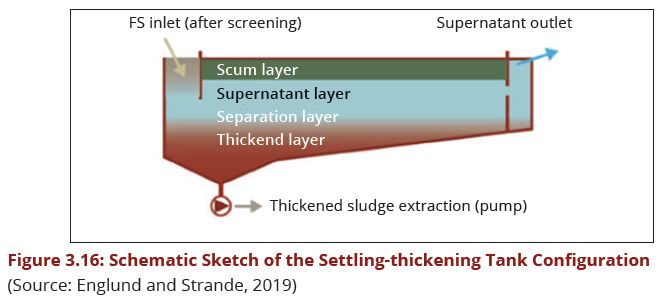

The main treatment objective of settling-thickening tanks is solid-liquid separation. Pathogen inactivation does not occur, and both liquid effluent and settled sludge require further treatment. Thickened sludge is normally removed after 5 to 30 days by a combination of pumps, front-loaders, and/or manually with shovels. The loading period should be adjusted with the TSS in the supernatant layer. If the outlet’s TSS concentration is too high, adjustments are required. There are normally two parallel tanks to allow for sludge removal and maintenance. Settling-thickening tanks have an inlet with a baffle to ensure quiescent flow, and an outlet with a baffle to allow only the supernatant to pass through the outlet. Figure 3.16 presents a schematic sketch of a typical settling-thickening tank. The floor is commonly either sloped so sludge can be pumped out, or else flat with access for removal by a front loader. Total suspended solids settle out into the thickened layer, and fats, oils and grease float in the scum layer.

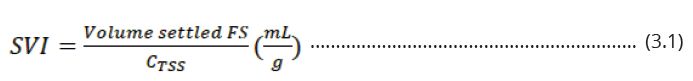

Prior to designing a settling-thickening tank, tests should be conducted with Imhoff cones to determine the settleability of the specific sludge. Settleability (recommended to be <100 mL/g TSS for settling) is determined by the Sludge Volume Index (SVI) and is estimated by settling of 1 litre of FS in Imhoff cones or columns for 30 to 60 minutes. The SVI is then calculated from the volume that settles at the bottom of these Imhoff cones divided by the initial total suspended solids concentration, CTSS.

In general, it has been observed that sludge that is more stable, settles better than sludge that has been stored in the containment for shorter periods of time. Treatment performance can be measured by TSS concentrations in the effluent/ supernatant.

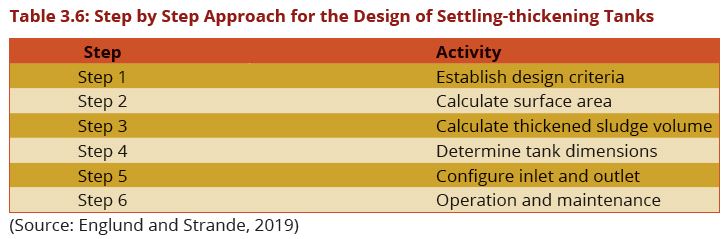

Sizing settling-thickening tanks

The approach taken for the sizing of settling-thickening tanks is summarized in

Table 3.6.

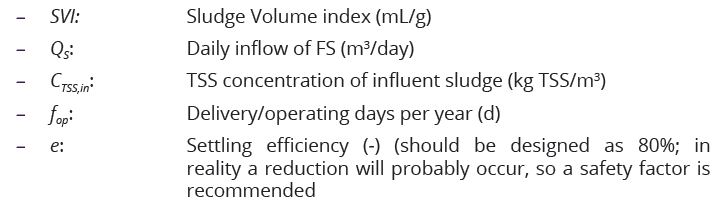

Step 1: Establish design criteria

The design of settling-thickening tanks is based on the TSS concentration of the

incoming sludge and its settleability. FS can either be discharged directly to the

settling thickening tanks, in which case following the Q&Q method to determine

quantities and qualities and quantities would be most appropriate, or can be

loaded using other technologies. The following parameters are important:

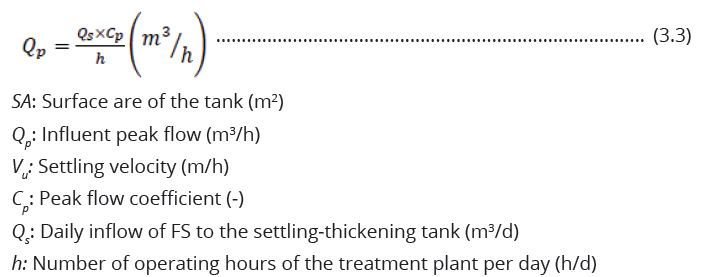

Step 2: Calculate surface area

The surface area is calculated based on the peak flow to ensure enough time for

the particles to settle.

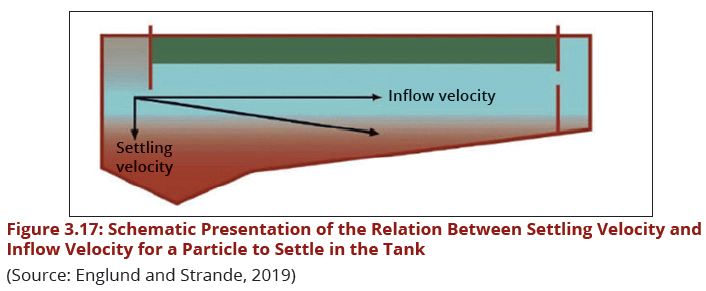

Based on existing experience, the settling velocity can be estimated as 0.5 m/h in rectangular settling-thickening tanks to treat FS with a SVI of less than 100 mL/g TSS. The tank is designed based on the desired removal of particles from the supernatant to the solids layer. In order for the particles to settle in the tank, a settling velocity greater than the inflow velocity is required, as shown in Figure 3.17. The recommended ratio between width and length is between 1:10 and 1:5. Lower settling velocities require longer tanks for particles to settle and remain in the tank. Depending on the planned operation of the tank, the design will vary. Manual emptying, either by truck or pump, of solids will result in different layouts and loading and discharge cycles. The calculated area should be doubled so that two parallel-operated settling-thickening tanks can receive discharged FS.

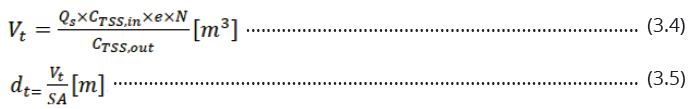

Step 3: Sizing of thickened sludge layer

The thickened sludge layer depth will vary with TSS concentration and will govern

the design of the settling-thickening tank.

Vt: Volume of thickened sludge storage zone (m3)

Qs: Daily inflow of FS to the settling-thickening tank (m3/d)

CTSS,in: TSS concentration of incoming FS (kg TSS/m3)

CTSS,out: TSS concentration of thickened FS (kg TSS/m3)

e: Settling efficiency

N: FS loading time (d)

dt: Thickened FS depth (m)

To find out how much sludge has accumulated in the thickened sludge layer, the average daily inflow is used. However, in reality the FS loading period (N) is also determined by a trade off or consideration of the treatment technologies that then follow, although it should not exceed four weeks. As a principle, the more time the thickened FS has to compact, the more challenging the removal with pumps will be. Expected TSS concentrations in the solids and supernatant layers can be estimated by using Imhoff cones or column testing prior to designing the system.

Step 4: Determine tank depth

The total depth is established by assumptions of the scum, supernatant and

separation layer depth. Nevertheless, excavation costs for building tanks are

commonly high and are a limiting factor in the maximum depth. Preliminary

guidelines based on studies in Accra are presented in Table 3.7.

Previous Page: Chapter_Two:_Planning_for_Sanitation_Projects << >> Next Page: Chapter_Four:_Off-Site_Sanitation_Systems