Difference between revisions of "Chapter Five: Pipelines Design"

| (24 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | The quantity of water to be supplied to a particular community has to be conveyed from source to consumers. Normally, the medium through which water has to be conveyed in pipelines. This chapter describes the pipelines | + | =Chapter Five:Pipelines Design= |

| − | + | <div style="text-align: justify"> | |

| − | + | The quantity of water to be supplied to a particular community has to be | |

| + | conveyed from a source to consumers. Normally, the medium through which | ||

| + | water has to be conveyed is in pipelines. This chapter describes the design of | ||

| + | pipelines. It presents the calculation of pipelines hydraulics and associated | ||

| + | design approaches. | ||

| + | ==Design Requirements Of Pipelines == | ||

There are five principle operational requirements for a pipeline. The requirements are; | There are five principle operational requirements for a pipeline. The requirements are; | ||

*It must convey the quantity of water required, | *It must convey the quantity of water required, | ||

| Line 10: | Line 15: | ||

*The material from which it is made should not adversely affect the quality of the water being conveyed. | *The material from which it is made should not adversely affect the quality of the water being conveyed. | ||

| − | + | == Types Of Pipelines == | |

| − | |||

Broadly, there are two types of pipelines which should be considered for design. They are transmission and distribution systems. Transmission and distribution systems vary in size and complexity but they all have the same basic purpose, which is to deliver water from the source(s) to the consumer. | Broadly, there are two types of pipelines which should be considered for design. They are transmission and distribution systems. Transmission and distribution systems vary in size and complexity but they all have the same basic purpose, which is to deliver water from the source(s) to the consumer. | ||

| − | + | == Right Of Way for Water Pipelines == | |

| − | |||

When designing a water supply project, pipeline route should be located. It should be accomplished by ensuring to obtain pipeline way-leaves. For security reasons we propose marker posts to be provided for the boundaries of the way-leave. For all pipelines it is important to obtain and secure a way-leave so as to avoid problems later on. Even in road reserves the alignment should be agreed with the road authority in advance and officially recorded so that even many years later there can be no argument when it comes to any dispute or compensation claim. | When designing a water supply project, pipeline route should be located. It should be accomplished by ensuring to obtain pipeline way-leaves. For security reasons we propose marker posts to be provided for the boundaries of the way-leave. For all pipelines it is important to obtain and secure a way-leave so as to avoid problems later on. Even in road reserves the alignment should be agreed with the road authority in advance and officially recorded so that even many years later there can be no argument when it comes to any dispute or compensation claim. | ||

| − | + | ===Methods of Water Transmission and Distribution === | |

| − | + | There are three (3) methods that should be considered when transporting water from the source to the treatment plant, if any, and the distribution system, and eventually reach consumers. The methods are; | |

| − | There are three (3) methods | ||

* Through gravity flow | * Through gravity flow | ||

* Through pumping with storage | * Through pumping with storage | ||

* Through direct pumping to the distribution system | * Through direct pumping to the distribution system | ||

| − | + | === Gravity Flow === | |

| + | This is the ideal set-up when the location of the water source is at a considerably | ||

| + | higher elevation than the area to be served. The operation cost of a gravity system | ||

| + | is very low, as it does not require energy cost. | ||

| − | + | ===Pumping with Storage === | |

| + | Water is either (a) pumped to a distribution pipe network, then to consumers, | ||

| + | with excess water going to a storage tank, or (b) pumped to a storage tank first, | ||

| + | then distributed by gravity from the tank to the consumers. The maintenance | ||

| + | and operation cost of this system is higher than the gravity system. | ||

| − | + | ===Direct Pumping to the Distribution System === | |

| + | In this system, water is pumped directly from the source to the distribution | ||

| + | system to the consumers. Where capital cost for a reservoir is not affordable at | ||

| + | the initial stage of the water system, direct pumping to the distribution is usually | ||

| + | resorted to. Variable-speed or variable frequency drive pumps are most ideal for | ||

| + | direct pumping operations, but the capital costs for such equipment are higher | ||

| + | than for conventional water pumps. | ||

| − | + | == Pipeline Hydraulics Assessment == | |

| − | + | ===Pressure === | |

| + | Pressure is generally expressed in N/m2, also called Pascal. Because of the level or | ||

| + | amount of pressure in a water supply system, pressure is commonly expressed | ||

| + | in kilopascals (kPa) or simply in meters (m). | ||

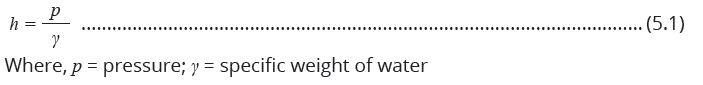

| − | + | Pressure increases linearly with the depth of water. For water at rest, the variation | |

| + | of pressure over depth is linear. The pressure exerted by a column of water is | ||

| + | called pressure head (h) and can be calculated using the formula below: | ||

| − | + | [[Image:Figure5.1.JPG|703px|link=DCOM_Volume_I]] <br> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | === Determination of Head Losses === | ||

The commonly used formulae for computation of head loss due to friction (also called friction loss) are: | The commonly used formulae for computation of head loss due to friction (also called friction loss) are: | ||

* Darcy-Weisbach formula | * Darcy-Weisbach formula | ||

| Line 58: | Line 66: | ||

* Combined Darcy-Weisbach and Colebrook-White equation | * Combined Darcy-Weisbach and Colebrook-White equation | ||

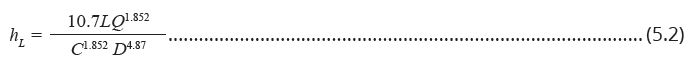

| − | This Manual recommends the use of Hazen Williams among the above | + | This Manual recommends the use of Hazen Williams among the above formulae. |

| + | The formula, which is the most widely used, relates the velocity of the flow, | ||

| + | hydraulic mean radius and hydraulic gradient. In terms of head loss due to | ||

| + | friction, the formula is: | ||

| − | + | [[Image:Figure5.2.JPG|698px|link=DCOM_Volume_I]] <br> | |

| − | |||

| − | |||

Where, | Where, | ||

| Line 70: | Line 79: | ||

Q = pipeline flow rate (m<sup>3</sup>/s) | Q = pipeline flow rate (m<sup>3</sup>/s) | ||

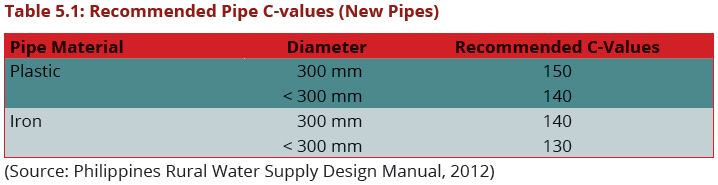

| − | The C-value is a carrying capacity factor that is sometimes referred to as the roughness coefficient, which varies depending on the pipe material being considered. Higher C-values represent smoother pipes and lower C-values are for rougher pipes. Higher C-values indicate higher carrying capacities. C-values increase with pipe size but decrease with pipe age. Although C-values are affected by changes in flow rates, the effect is negligible. Thus, network designers usually assume uniform C-value for different flow rates. Table 5.1 presents the recommended C-values for various pipe materials. | + | The C-value is a carrying capacity factor that is sometimes referred to as the |

| + | roughness coefficient, which varies depending on the pipe material being | ||

| + | considered. Higher C-values represent smoother pipes and lower C-values are | ||

| + | for rougher pipes. Higher C-values indicate higher carrying capacities. C-values | ||

| + | increase with pipe size but decrease with pipe age. Although C-values are | ||

| + | affected by changes in flow rates, the effect is negligible. Thus, network designers | ||

| + | usually assume uniform C-value for different flow rates. Table 5.1 presents the | ||

| + | recommended C-values for various pipe materials. | ||

| + | |||

| + | [[Image:Table5.1.JPG|718px|link=Chapter_Five:_Pipelines_Design]] <br> | ||

| + | |||

| + | Another contributing component of total head loss is the head loss from | ||

| + | turbulence due to pipe fittings and appurtenances. This category of losses is | ||

| + | sometimes called minor losses. The total minor losses in a distribution network | ||

| + | is usually insignificant compared to the total head loss of the system, thus, the | ||

| + | designer may ignore this component in network analysis computation. | ||

| + | |||

| + | == Water Supply Transmission System == | ||

| + | The transmission system’s function is to transport water from source to the | ||

| + | reservoir if any, and to the distribution point. Water conduits for the transmission | ||

| + | system may be canals, aqueducts or tunnels, free-flow pipelines, or pressure | ||

| + | pipelines. The transmission of water will either be by gravity or pumping. Pressure | ||

| + | pipeline is generally the type of water conduit used for water supply transmission | ||

| + | systems. | ||

| + | |||

| + | === Determination of Transmission Pipe Size === | ||

| + | Normally, the sizing of the transmission main is dependent on the total storage | ||

| + | capacity and the way the supply is transmitted to the distribution system. The | ||

| + | main should have at least the carrying capacity to supply water at a rate equivalent | ||

| + | to the maximum day demand of the system for a given design year. | ||

| + | |||

| + | ''As a rule of thumb, for transmission by pumping, it is advisable to assume a preliminary head loss (hL) of about 5.0 m/km of pipeline. (As much as possible, head loss should be limited to 10.0 m/km of pipeline for transmission by pumping).'' For a gravity system with a considerably elevated source (e.g. highland springs), the transmission line could afford to have higher head losses as long as the remaining pressure head at the downstream end is sufficient for the distribution system’s needs. For a gravity system with source elevation that is not much higher than the distribution system, the head losses are lowered to attain just sufficient pressure head in the distribution system. | ||

| + | |||

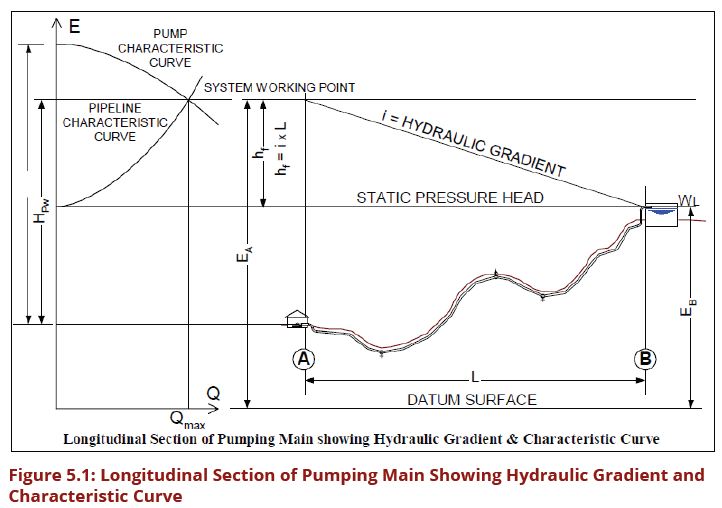

| + | ===Maximum Pressure === | ||

| + | The pipe material should be selected to withstand the highest possible pressure | ||

| + | that can occur in the pipeline. For a gravity system, the worst-case scenario is for | ||

| + | pressure to be at its maximum during shut-off at the downstream end when the | ||

| + | static pressure is too high. For the transmission line design, a maximum computed | ||

| + | HGL based on a minimum supply rate equivalent to 0.3 times the average day | ||

| + | demand should be examined. However, practical experience from the ground | ||

| + | suggests that there is no need to limit the maximum allowable pressure to 60m | ||

| + | head. Instead, considerations should be given on the basis of the economic | ||

| + | grounds. However, in any circumstances where the maximum allowable pressure | ||

| + | be exceeded, break pressure tanks should be installed along the main. The break | ||

| + | pressure tank will limit the static pressure by providing an open water surface at | ||

| + | certain points of the transmission line. Design of transmission line should be | ||

| + | undertaken with the use of hydraulic computer software, which is discussed | ||

| + | in the succeeding sections. Figure 5.1 below shows the longitudinal section of | ||

| + | pumping main showing hydraulic gradient and characteristic curve | ||

| + | |||

| + | [[Image:Figure5.1b.JPG|722px|link=Chapter_Five:_Pipelines_Design]] <br> | ||

| + | |||

| + | ==Distribution System == | ||

| + | For purposes of designing pipelines, the distribution systems are considered in | ||

| + | terms of the topology or layout that is used. There are two types:<br> | ||

| + | * Branched system and | ||

| + | * Looped System | ||

| + | |||

| + | ===Branched System === | ||

| + | Also referred to as a Dead-end System, the size of the main line in this distribution | ||

| + | system decreases as its distance from the source increases, in consideration that | ||

| + | the further pipes have to carry less water. The design of a branched system is | ||

| + | generally straightforward, where the direction of water flow in all pipes and the | ||

| + | flow rate can be readily determined. | ||

| + | |||

| + | One of the advantages of a branched system is generally lower costs.The | ||

| + | disadvantages are: | ||

| + | |||

| + | * A main break will cause all downstream consumers to be out of service. | ||

| + | * It results in poor chlorine residuals and aging of water in low-demand areas. | ||

| + | * During high demands, the velocities are faster, hence head losses are higher. | ||

| + | |||

| + | === Looped System === | ||

| + | A distribution network is looped when there are only a few or no pipe dead-ends, | ||

| + | such that water can move through the system freely. The advantages of a looped | ||

| + | system are: | ||

| + | |||

| + | * The lower water velocities in the main reduce head losses, resulting in greater capacity, | ||

| + | * Main breaks can be isolated, minimizing service interruptions to consumers, | ||

| + | * Usually better chlorine residual content is achieved. | ||

| + | |||

| + | The disadvantage is generally more costs because of the need for more pipes to | ||

| + | create the loops. | ||

| + | |||

| + | A major transmission design consideration is to ensure that if any section of | ||

| + | the distribution main fails or needs repair, that section can be isolated without | ||

| + | disrupting service to all or a great number of users in the network. Figure 5.2 | ||

| + | illustrates the dead-end (A) and the looped system (B). | ||

| + | |||

| + | [[Image:Figure5.2c.JPG|717px|link=Chapter_Five:_Pipelines_Design]] <br> | ||

| + | |||

| + | == Pipe Network Analysis == | ||

| + | Pipe network analysis involves a detailed and careful scrutiny of the fluid flow | ||

| + | through a hydraulic network containing several interconnected branches and | ||

| + | loops. In the design of a distribution system, a pipe network analysis must be | ||

| + | done to determine the flow rates and pressure drops in the individual sections of | ||

| + | the network, thus giving a basis for selecting pipe diameters. | ||

| + | |||

| + | === Network Analysis by Conventional Method(Hardy Cross) === | ||

| + | The most common conventional method (not using computers) that is used in | ||

| + | designing hydraulic networks is the Hardy Cross algorithm method. This involves | ||

| + | iterative trial and error. One approach of Hardy Cross is the method of balancing | ||

| + | the heads on the nodes by adjusting assumed flows in the pipe network. | ||

| + | |||

| + | Nowadays, manual computation for hydraulic network analysis is only acceptable | ||

| + | when applied to systems with only a single pipeline or branched network with no | ||

| + | loop. For networks with loops, it is highly recommended to use one of the more | ||

| + | accurate, fast and convenient network modelling computer software, which are | ||

| + | discussed in the following section. | ||

| + | |||

| + | ===Network Analysis by Computer Software=== | ||

| + | There are several pipe network analysis software (also called network simulation | ||

| + | software, or hydraulic network modeling software) that mathematically solve | ||

| + | hydraulic equations for all interconnections, branches and loops of the pipe | ||

| + | network. With the advent of such powerful software, the conventional methods | ||

| + | of water distribution design have been mostly discarded. The computer software | ||

| + | requires the designer to create a water supply system model by inputting in | ||

| + | the computer program information that includes pipe lengths, junctions or | ||

| + | node elevations, connectivity of the pipes and nodes, demand in each node, | ||

| + | information on pumps, elevations of reservoirs, elevations, and yield of sources. | ||

| + | |||

| + | Among the current software available on the weband from proprietary sources, | ||

| + | the EPANET is highly recommended. EPANET is public domain software | ||

| + | developed by Water Supply and Water Resources Division (formerly the Drinking | ||

| + | Water Research Division) of the U.S. Environmental Protection Agency that can | ||

| + | be downloaded for free on the internet. The software tracks the flow of water in | ||

| + | each pipe, the pressure at each node, and the height of water in each tank. | ||

| + | |||

| + | The important features of EPANET for distribution network design is its ability to: | ||

| + | * Handle systems of any size; | ||

| + | * Compute friction head loss using the Hazen-Williams, the Darcy Weisback, or the Chezy-Manning head loss formula; | ||

| + | * Includes minor head losses for bends, fittings, etc.; | ||

| + | * Models constant or variable speed pumps; | ||

| + | * Allows storage tanks to have any shape. | ||

| + | |||

| + | The design process using EPANET usually involves the (a) layout of the system configuration including locations of sources and storage facilities, (b) determination of the distribution of demands to the nodes, input of network data, running hydraulic simulation, viewing results in any of the variety of formats, modifying the model by editing the network data, and modifying the model until the design criteria are met or results are acceptable. | ||

| + | |||

| + | '''(a) Steps in Distribution System Design Using Computer Software'''<br> | ||

| + | |||

| + | '''Step 1: Base Mapping'''<br> | ||

| + | Detailed maps of the project area should be gathered as a basis for pipeline | ||

| + | alignment, distance and elevations. These should be obtained from field | ||

| + | topographical surveys or certified suppliers of map products. For preliminary | ||

| + | analyses, the Google Earth (http://earth.google.com) internet site which makes it | ||

| + | possible to view and print aerial images of the area being designed may be used. | ||

| + | However, accuracy of elevations from open source products is discouraged. | ||

| + | |||

| + | The information in the maps should be correlated to produce a base map, on | ||

| + | which the proposed system layout will be drawn. The designer should conduct | ||

| + | an ocular inspection of the whole project area to verify, validate and update the | ||

| + | information on the source maps. The resulting base map must include positions | ||

| + | and information on roads, streets, rivers, creeks, elevations, topographic contours | ||

| + | and locations of built-up areas. It should also provide relevant information like | ||

| + | potential large consumers, e.g., piggeries and poultry farms. Ideally, the base | ||

| + | map should be scaled.. | ||

| + | |||

| + | '''Step 2: Water Demand Projection'''<br> | ||

| + | The average day demand for the design year will be the basis of the hydraulic | ||

| + | network analysis. The demand condition will be varied by adjusting the demand | ||

| + | factor; that is 1 for the average day demand condition, 1.3 for the maximum | ||

| + | day demand and 2.5 – 3 for the peak-hour demand. More details on demand | ||

| + | projections are given in Chapter Four. | ||

| + | |||

| + | '''Step 3: Tentative Layout'''<br> | ||

| + | Using the base map, the designer should next develop a tentative layout of the pipe network, which should also show the positions of the source facilities and reservoir(s). | ||

| + | Pipelines are to be laid on road right of way, and the network should cover the target consumers. Nodes are placed at locations for pipe junctions, street or road junctions and intersections, locations for water points, demand centres, and not more than 100 metres from the nearest node. In systems where it is expected that pressure will be generally low or fluctuating, nodes are placed at the highest points of the service area. | ||

| + | |||

| + | '''Step 4: Distribution of Demands'''<br> | ||

| + | It is important to plot the town or community boundaries and the service area delineation on the base map. Once the tentative layout (with nodes) is plotted on the base map, the service area should be sub-divided into node areas. This will give the designer a working idea of the respective number of houses within the area covered by each node. | ||

| + | |||

| + | The projected average day demand for the design year is distributed to all the nodes within its delineated service area. The distribution of demands should take into consideration the relative number of houses for the different node areas. | ||

| + | |||

| + | '''Step 5: Encoding of Input Data'''<br> | ||

| + | Most of the hydraulic analysis software have common input data requirements. These data are grouped into pipe data and node data. Pipe data are the assigned pipe number, pipe diameter (mm), C-value, the pipe nodes, and length (m). Node data are node number, elevation (m), and water demand (lps). Usually, the values of the design criteria are required by computer software. | ||

| + | |||

| + | '''Step 6: Hydraulic Network Simulation:'''<br> | ||

| + | This step is done by the computer software. If all the data required have been input by the designer, the software could proceed with its hydraulic run. The software computes the head losses (m) in each pipe, the rate of head loss (m/km) in each pipe, the flow velocities (m/s), and the pressure in each node (m). | ||

| + | |||

| + | The model is run for: (a) its peak-hour demand condition, to check for the possible value of the pressure of the minimum system; and (b) its minimum demand condition, to check for the value of the possible maximum pressure in the network. | ||

| + | |||

| + | '''Step 7: Examination of Hydraulic Run Results'''<br> | ||

| + | Usually, all possible hydraulic parameters can be shown from the computer run results. Of these parameters, the designer must examine two important results very closely: (a) The low system pressure points that are below the 7 m pressure and the affected nodes, and (b) the pipes that have high head loss per km in excess of the 10 m/1,000 m pipeline criteria. | ||

| + | |||

| + | The designer must also examine the balancing flows of the reservoir and analyze if the reservoir discharge or inflow is reasonable for its storage size. | ||

| + | |||

| + | '''Step 8: Adjusting Assumed Parameters of the Elements:'''<br> | ||

| + | Based on the results of the computer simulation, the designer will improve | ||

| + | the network model by adjusting the pipe and node data for specific elements, | ||

| + | particularly for those that did not meet the design criteria. For example, for pipes | ||

| + | that have high resulting head losses, the designer will have to increase the pipe | ||

| + | size to the next larger diameter. If there is a system pressure that is below 7 m, | ||

| + | the designer could replace some of the pipes leading to the affected node with | ||

| + | a larger diameter. The height of the reservoir could be adjusted if needed to | ||

| + | achieve a good system pressure. | ||

| + | |||

| + | The adjusted model is run again in the software. After the run, the results | ||

| + | are examined and the model readjusted. The above cycle is repeated until an | ||

| + | acceptable hydraulic model is achieved. | ||

| + | |||

| + | '''Step 9: Finalizing the Network Configuration'''<br> | ||

| + | The model is subjected to repeated simulation and data adjustments until an | ||

| + | acceptable network configuration is reached. | ||

| + | |||

| + | === Pipeline Design Criteria === | ||

| + | The pipeline should be designed to withstand the following; | ||

| + | * Internal test pressure of water, | ||

| + | * Water hammer (positive surge), | ||

| + | * Vacuum and negative surge, | ||

| + | * External pressures when laid below ground (overburden and surcharge), | ||

| + | * Conveyance water temperature (thermoplastic pipes), | ||

| + | * Maximum working temperature (ferrous pipe coatings), | ||

| + | * Temperature stresses when laid above ground, | ||

| + | * Flexural stresses when laid over supports, constructed at intervals or on bridges, | ||

| + | * Longitudinal stresses due to flow at tees, tapers and bends, | ||

| + | * Foundation reaction depending upon the nature of support, | ||

| + | * Handling stresses, | ||

| + | |||

| + | For flexible pipes (thermoplastic and steel) the following criteria should be met; | ||

| + | |||

| + | * The pipe deflection (out-or-roundness) must not exceed the allowable limit; | ||

| + | * The combined stress or stain in the pipe wall must not exceed the allowable limit, and | ||

| + | * The factor of safety against buckling must be adequate; | ||

| + | |||

| + | For semi-rigid pipes (ductile iron) the following criteria should be met: | ||

| + | |||

| + | * The pipe deflection (out-or-roundness) should not exceed the allowable limit; | ||

| + | * The pipe wall bending stress should not exceed the allowable limit. | ||

| + | |||

| + | The distribution pipelines should be designed to handle the peak hour demand of the system under the following criteria; | ||

| + | |||

| + | [[Image:Table5.2.JPG|720px|link=Chapter_Five:_Pipelines_Design]] <br> | ||

| + | |||

| + | [[Image:Table5.2b.JPG|720px|link=Chapter_Five:_Pipelines_Design]] <br> | ||

| + | |||

| + | ==Pipeline Materials Selection == | ||

| + | === Considerations in Selecting Pipeline Materials === | ||

| + | |||

| + | ==== Flow Characteristics ==== | ||

| + | The friction head loss is dependent on the flow characteristics of pipes. Friction | ||

| + | loss is a power loss and thus may affect the operating costs of the system if a | ||

| + | pump is used. | ||

| + | |||

| + | ==== Pipe Strength==== | ||

| + | Select the pipe with a working pressure and bursting pressure rating adequate to meet the operating conditions of the system. Standard water pipes are satisfactory usually only in low pressure water supply systems. | ||

| + | |||

| + | ==== Durability ==== | ||

| + | Select the type of pipe with good life expectancy given the operating conditions and the soil conditions of the system. It should have an expected life of 30 years or more. | ||

| + | |||

| + | ==== Type of Soil ==== | ||

| + | Select the type of pipe that is suited to the type of soil in the area under consideration. For instance, acidic soil can easily corrode G.I. pipes and very rocky soil can damage plastic pipes unless they are properly bedded in sand or other type of material. | ||

| + | |||

| + | ==== Availability ==== | ||

| + | Select locally manufactured and/or fabricated pipes whenever available. | ||

| + | |||

| + | ====Cost of Pipes ==== | ||

| + | Aside from the initial cost of pipes, the cost of installation should be considered. This is affected by the type of joint (such as screwed, solvent weld, slip joint, fussion welding etc.), weight of pipe (for ease of handling), depth of bury required, and width of trench and depth of cover required. | ||

| + | |||

| + | === Types of Pipe Materials Available === | ||

| + | |||

| + | ==== Galvanized Iron (GI) Pipes ==== | ||

| + | GI pipes are available in sizes of 13, 19, 25, 31, 38, 50, 63 and 75 mm and in lengths of 6 m. They are joined by means of threaded couplings. | ||

| + | |||

| + | Advantages | ||

| + | * Strong against internal and external pressure. | ||

| + | * Can be laid below or above ground. | ||

| + | * People in rural areas know how to install these kind of pipes. | ||

| + | |||

| + | Disadvantages | ||

| + | * GI Pipes can easily be corroded, thus the service life is short. | ||

| + | * These have rougher internal surface compared to plastic pipes, hence, have higher friction head losses. | ||

| + | |||

| + | ==== Plastic Pipes ==== | ||

| + | Polyvinyl Chloride (PVC) and Polyethylene (PE) are commercial plastic pipes. They are available in different pressure ratings and sizes of 13, 19, 25, 31, 38, 50, 63, 75, 100 up to 200 mm. PVC is supplied in lengths of 3 m and 6 m while PE is available in rolls and, for diameters greater than 100 mm, in straight lengths. Suppliers have to be consulted with respect to the pressure ratings to be used. PE pipes are joined by butt-welding. PVC pipes can be joined either through solvent cement welding or through the use of special sockets with rubber rings. | ||

| + | |||

| + | Advantages | ||

| + | * Smooth internal surface. | ||

| + | * Resistant to corrosion. | ||

| + | * Extremely light and easy to handle. | ||

| + | * Do not form encrustation | ||

| + | |||

| + | Disadvantages<br> | ||

| + | * Lose strength at high temperatures (500° C+), | ||

| + | * Not suitable for laying above the ground, | ||

| + | * Can deform during storage, | ||

| + | * Require good and carefully prepared bedding materials, | ||

| + | * Rubber rings can be eaten by some termites if appropriate pipes lubricant is not used in jointing. Thus, the use of edible oil should be avoided. | ||

| + | * When joints of fusion welding is opted for, local expertise is scarce. | ||

| + | |||

| + | [[Image:Table5.3.JPG|722px|link=DCOM_Volume_I]] <br> | ||

| + | |||

| + | == Appurtenances For Transmission And Distribution Mains == | ||

| + | Pipe fittings are those specially manufactured fittings used to facilitate changes | ||

| + | in direction, changes in diameter, the making of branches etc. to the pipeline. | ||

| + | Further, fittings are needed to install valves, meters and other mechanical devices | ||

| + | and to allow for the change from one pipe material to another or diameter | ||

| + | changes. | ||

| + | |||

| + | ===Valves === | ||

| + | One of the most important types of appurtenances is the valve. A valve is a device that can be opened and closed to different extents (called throttling) to vary its resistance to flow, thereby controlling the movement of water through a pipeline. Valves can be classified into five general categories as follows: | ||

| + | |||

| + | ==== Isolation Valves ==== | ||

| + | Perhaps the most common valve in the water distribution system is the isolation valve, which can be manually closed to block the flow of water. Isolation valves include gate valves (the most popular type), butterfly valves, globe valves, and plug valves. | ||

| + | |||

| + | ==== Check Valves ==== | ||

| + | Check valves, also called directional valves, are used to ensure that water can flow only in one direction through a pipeline. | ||

| + | |||

| + | ==== Float Valves ==== | ||

| + | Many water utilities employ devices called float valves at the point where a pipeline enters a tank. When tank level rises to a specified upper limit, the valve closes to prevent any further flow from entering, thus eliminating overflow. | ||

| + | |||

| + | ==== Air Release Valves ==== | ||

| + | These valves are provided in system high points, where trapped air settles, and at changes in grade, where pressures are most likely to drop below ambient or atmospheric conditions. | ||

| + | |||

| + | ==== Pressure Reducing Valves ==== | ||

| + | Pressure reducing valves (PRVs) throttle automatically to prevent the downstream hydraulic grade from exceeding a set value and are used in situations where high downstream pressures could cause damage. | ||

| + | |||

| + | ====Washout valves ==== | ||

| + | To be provided at the lowest points for the purpose of flushing the pipeline. | ||

| + | |||

| + | ===Fittings === | ||

| + | Fittings are installed in the pipelines for the following purposes; | ||

| + | * To connect the same type and size of pipe - Union: Unions are provided in the pipeline for ease of repair. Unions are usually installed at 60-meters intervals on straight pipelines. Coupling: Used in joining 2 pipes of the same diameter. It is cheaper than unions. | ||

| + | * To connect two pipes of different sizes- Reducers are used when there is a reduction of pipe size and include bushes and elbows for galvanized iron pipes. Also available are reducing elbows, tees and crosses. | ||

| + | * To change the direction of flow - Elbow; to divide the flow into two - Tee; to divide the flow into three - Cross. | ||

| + | * To stop the flow - caps, plugs and blind flanges. | ||

| − | + | '''REFERENCES'''<br> | |

| − | + | MoW 3<sup>rd</sup> Edition Design Manual, 2009<br> | |

| − | + | Philipines Rural Water Supply Design Manual, 2012 | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Previous Page: [[Chapter_Four:_Water_Demand_Assessment|Chapter_Four:_Water_Demand_Assessment]] << >> Next Page: [[Chapter_Six:_Pumping_Systems|Chapter_Six:_Pumping_Systems]] | |

| + | </div> | ||

Latest revision as of 16:17, 20 July 2022

Contents

- 1 Chapter Five:Pipelines Design

- 1.1 Design Requirements Of Pipelines

- 1.2 Types Of Pipelines

- 1.3 Right Of Way for Water Pipelines

- 1.4 Pipeline Hydraulics Assessment

- 1.5 Water Supply Transmission System

- 1.6 Distribution System

- 1.7 Pipe Network Analysis

- 1.8 Pipeline Materials Selection

- 1.9 Appurtenances For Transmission And Distribution Mains

1 Chapter Five:Pipelines Design

The quantity of water to be supplied to a particular community has to be conveyed from a source to consumers. Normally, the medium through which water has to be conveyed is in pipelines. This chapter describes the design of pipelines. It presents the calculation of pipelines hydraulics and associated design approaches.

1.1 Design Requirements Of Pipelines

There are five principle operational requirements for a pipeline. The requirements are;

- It must convey the quantity of water required,

- It must be capable of resisting all external and internal forces,

- It must be durable and meet the design working life,

- It must be properly laid and embedded,

- The material from which it is made should not adversely affect the quality of the water being conveyed.

1.2 Types Of Pipelines

Broadly, there are two types of pipelines which should be considered for design. They are transmission and distribution systems. Transmission and distribution systems vary in size and complexity but they all have the same basic purpose, which is to deliver water from the source(s) to the consumer.

1.3 Right Of Way for Water Pipelines

When designing a water supply project, pipeline route should be located. It should be accomplished by ensuring to obtain pipeline way-leaves. For security reasons we propose marker posts to be provided for the boundaries of the way-leave. For all pipelines it is important to obtain and secure a way-leave so as to avoid problems later on. Even in road reserves the alignment should be agreed with the road authority in advance and officially recorded so that even many years later there can be no argument when it comes to any dispute or compensation claim.

1.3.1 Methods of Water Transmission and Distribution

There are three (3) methods that should be considered when transporting water from the source to the treatment plant, if any, and the distribution system, and eventually reach consumers. The methods are;

- Through gravity flow

- Through pumping with storage

- Through direct pumping to the distribution system

1.3.2 Gravity Flow

This is the ideal set-up when the location of the water source is at a considerably higher elevation than the area to be served. The operation cost of a gravity system is very low, as it does not require energy cost.

1.3.3 Pumping with Storage

Water is either (a) pumped to a distribution pipe network, then to consumers, with excess water going to a storage tank, or (b) pumped to a storage tank first, then distributed by gravity from the tank to the consumers. The maintenance and operation cost of this system is higher than the gravity system.

1.3.4 Direct Pumping to the Distribution System

In this system, water is pumped directly from the source to the distribution system to the consumers. Where capital cost for a reservoir is not affordable at the initial stage of the water system, direct pumping to the distribution is usually resorted to. Variable-speed or variable frequency drive pumps are most ideal for direct pumping operations, but the capital costs for such equipment are higher than for conventional water pumps.

1.4 Pipeline Hydraulics Assessment

1.4.1 Pressure

Pressure is generally expressed in N/m2, also called Pascal. Because of the level or amount of pressure in a water supply system, pressure is commonly expressed in kilopascals (kPa) or simply in meters (m).

Pressure increases linearly with the depth of water. For water at rest, the variation of pressure over depth is linear. The pressure exerted by a column of water is called pressure head (h) and can be calculated using the formula below:

1.4.2 Determination of Head Losses

The commonly used formulae for computation of head loss due to friction (also called friction loss) are:

- Darcy-Weisbach formula

- Hazen-Williams formula

- Manning's formula

- Combined Darcy-Weisbach and Colebrook-White equation

This Manual recommends the use of Hazen Williams among the above formulae. The formula, which is the most widely used, relates the velocity of the flow, hydraulic mean radius and hydraulic gradient. In terms of head loss due to friction, the formula is:

Where, hL = head loss due to friction; L = distance between sections or length of pipeline (m); C = Hazen – Williams C-Value; D = internal diameter (m); Q = pipeline flow rate (m3/s)

The C-value is a carrying capacity factor that is sometimes referred to as the roughness coefficient, which varies depending on the pipe material being considered. Higher C-values represent smoother pipes and lower C-values are for rougher pipes. Higher C-values indicate higher carrying capacities. C-values increase with pipe size but decrease with pipe age. Although C-values are affected by changes in flow rates, the effect is negligible. Thus, network designers usually assume uniform C-value for different flow rates. Table 5.1 presents the recommended C-values for various pipe materials.

Another contributing component of total head loss is the head loss from turbulence due to pipe fittings and appurtenances. This category of losses is sometimes called minor losses. The total minor losses in a distribution network is usually insignificant compared to the total head loss of the system, thus, the designer may ignore this component in network analysis computation.

1.5 Water Supply Transmission System

The transmission system’s function is to transport water from source to the reservoir if any, and to the distribution point. Water conduits for the transmission system may be canals, aqueducts or tunnels, free-flow pipelines, or pressure pipelines. The transmission of water will either be by gravity or pumping. Pressure pipeline is generally the type of water conduit used for water supply transmission systems.

1.5.1 Determination of Transmission Pipe Size

Normally, the sizing of the transmission main is dependent on the total storage capacity and the way the supply is transmitted to the distribution system. The main should have at least the carrying capacity to supply water at a rate equivalent to the maximum day demand of the system for a given design year.

As a rule of thumb, for transmission by pumping, it is advisable to assume a preliminary head loss (hL) of about 5.0 m/km of pipeline. (As much as possible, head loss should be limited to 10.0 m/km of pipeline for transmission by pumping). For a gravity system with a considerably elevated source (e.g. highland springs), the transmission line could afford to have higher head losses as long as the remaining pressure head at the downstream end is sufficient for the distribution system’s needs. For a gravity system with source elevation that is not much higher than the distribution system, the head losses are lowered to attain just sufficient pressure head in the distribution system.

1.5.2 Maximum Pressure

The pipe material should be selected to withstand the highest possible pressure that can occur in the pipeline. For a gravity system, the worst-case scenario is for pressure to be at its maximum during shut-off at the downstream end when the static pressure is too high. For the transmission line design, a maximum computed HGL based on a minimum supply rate equivalent to 0.3 times the average day demand should be examined. However, practical experience from the ground suggests that there is no need to limit the maximum allowable pressure to 60m head. Instead, considerations should be given on the basis of the economic grounds. However, in any circumstances where the maximum allowable pressure be exceeded, break pressure tanks should be installed along the main. The break pressure tank will limit the static pressure by providing an open water surface at certain points of the transmission line. Design of transmission line should be undertaken with the use of hydraulic computer software, which is discussed in the succeeding sections. Figure 5.1 below shows the longitudinal section of pumping main showing hydraulic gradient and characteristic curve

1.6 Distribution System

For purposes of designing pipelines, the distribution systems are considered in

terms of the topology or layout that is used. There are two types:

- Branched system and

- Looped System

1.6.1 Branched System

Also referred to as a Dead-end System, the size of the main line in this distribution system decreases as its distance from the source increases, in consideration that the further pipes have to carry less water. The design of a branched system is generally straightforward, where the direction of water flow in all pipes and the flow rate can be readily determined.

One of the advantages of a branched system is generally lower costs.The disadvantages are:

- A main break will cause all downstream consumers to be out of service.

- It results in poor chlorine residuals and aging of water in low-demand areas.

- During high demands, the velocities are faster, hence head losses are higher.

1.6.2 Looped System

A distribution network is looped when there are only a few or no pipe dead-ends, such that water can move through the system freely. The advantages of a looped system are:

- The lower water velocities in the main reduce head losses, resulting in greater capacity,

- Main breaks can be isolated, minimizing service interruptions to consumers,

- Usually better chlorine residual content is achieved.

The disadvantage is generally more costs because of the need for more pipes to create the loops.

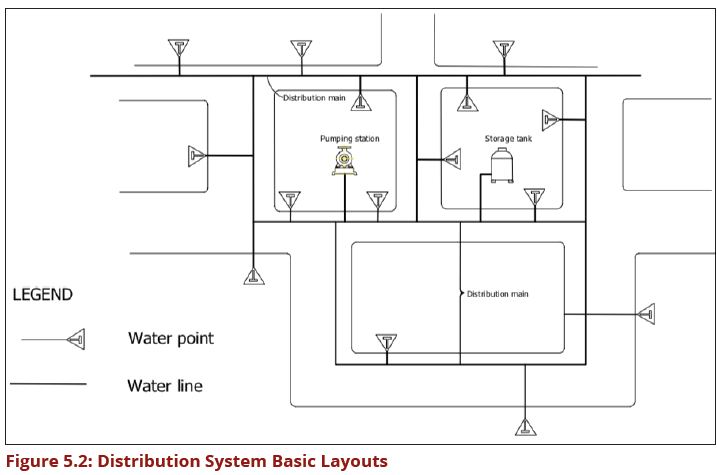

A major transmission design consideration is to ensure that if any section of the distribution main fails or needs repair, that section can be isolated without disrupting service to all or a great number of users in the network. Figure 5.2 illustrates the dead-end (A) and the looped system (B).

1.7 Pipe Network Analysis

Pipe network analysis involves a detailed and careful scrutiny of the fluid flow through a hydraulic network containing several interconnected branches and loops. In the design of a distribution system, a pipe network analysis must be done to determine the flow rates and pressure drops in the individual sections of the network, thus giving a basis for selecting pipe diameters.

1.7.1 Network Analysis by Conventional Method(Hardy Cross)

The most common conventional method (not using computers) that is used in designing hydraulic networks is the Hardy Cross algorithm method. This involves iterative trial and error. One approach of Hardy Cross is the method of balancing the heads on the nodes by adjusting assumed flows in the pipe network.

Nowadays, manual computation for hydraulic network analysis is only acceptable when applied to systems with only a single pipeline or branched network with no loop. For networks with loops, it is highly recommended to use one of the more accurate, fast and convenient network modelling computer software, which are discussed in the following section.

1.7.2 Network Analysis by Computer Software

There are several pipe network analysis software (also called network simulation software, or hydraulic network modeling software) that mathematically solve hydraulic equations for all interconnections, branches and loops of the pipe network. With the advent of such powerful software, the conventional methods of water distribution design have been mostly discarded. The computer software requires the designer to create a water supply system model by inputting in the computer program information that includes pipe lengths, junctions or node elevations, connectivity of the pipes and nodes, demand in each node, information on pumps, elevations of reservoirs, elevations, and yield of sources.

Among the current software available on the weband from proprietary sources, the EPANET is highly recommended. EPANET is public domain software developed by Water Supply and Water Resources Division (formerly the Drinking Water Research Division) of the U.S. Environmental Protection Agency that can be downloaded for free on the internet. The software tracks the flow of water in each pipe, the pressure at each node, and the height of water in each tank.

The important features of EPANET for distribution network design is its ability to:

- Handle systems of any size;

- Compute friction head loss using the Hazen-Williams, the Darcy Weisback, or the Chezy-Manning head loss formula;

- Includes minor head losses for bends, fittings, etc.;

- Models constant or variable speed pumps;

- Allows storage tanks to have any shape.

The design process using EPANET usually involves the (a) layout of the system configuration including locations of sources and storage facilities, (b) determination of the distribution of demands to the nodes, input of network data, running hydraulic simulation, viewing results in any of the variety of formats, modifying the model by editing the network data, and modifying the model until the design criteria are met or results are acceptable.

(a) Steps in Distribution System Design Using Computer Software

Step 1: Base Mapping

Detailed maps of the project area should be gathered as a basis for pipeline

alignment, distance and elevations. These should be obtained from field

topographical surveys or certified suppliers of map products. For preliminary

analyses, the Google Earth (http://earth.google.com) internet site which makes it

possible to view and print aerial images of the area being designed may be used.

However, accuracy of elevations from open source products is discouraged.

The information in the maps should be correlated to produce a base map, on which the proposed system layout will be drawn. The designer should conduct an ocular inspection of the whole project area to verify, validate and update the information on the source maps. The resulting base map must include positions and information on roads, streets, rivers, creeks, elevations, topographic contours and locations of built-up areas. It should also provide relevant information like potential large consumers, e.g., piggeries and poultry farms. Ideally, the base map should be scaled..

Step 2: Water Demand Projection

The average day demand for the design year will be the basis of the hydraulic

network analysis. The demand condition will be varied by adjusting the demand

factor; that is 1 for the average day demand condition, 1.3 for the maximum

day demand and 2.5 – 3 for the peak-hour demand. More details on demand

projections are given in Chapter Four.

Step 3: Tentative Layout

Using the base map, the designer should next develop a tentative layout of the pipe network, which should also show the positions of the source facilities and reservoir(s).

Pipelines are to be laid on road right of way, and the network should cover the target consumers. Nodes are placed at locations for pipe junctions, street or road junctions and intersections, locations for water points, demand centres, and not more than 100 metres from the nearest node. In systems where it is expected that pressure will be generally low or fluctuating, nodes are placed at the highest points of the service area.

Step 4: Distribution of Demands

It is important to plot the town or community boundaries and the service area delineation on the base map. Once the tentative layout (with nodes) is plotted on the base map, the service area should be sub-divided into node areas. This will give the designer a working idea of the respective number of houses within the area covered by each node.

The projected average day demand for the design year is distributed to all the nodes within its delineated service area. The distribution of demands should take into consideration the relative number of houses for the different node areas.

Step 5: Encoding of Input Data

Most of the hydraulic analysis software have common input data requirements. These data are grouped into pipe data and node data. Pipe data are the assigned pipe number, pipe diameter (mm), C-value, the pipe nodes, and length (m). Node data are node number, elevation (m), and water demand (lps). Usually, the values of the design criteria are required by computer software.

Step 6: Hydraulic Network Simulation:

This step is done by the computer software. If all the data required have been input by the designer, the software could proceed with its hydraulic run. The software computes the head losses (m) in each pipe, the rate of head loss (m/km) in each pipe, the flow velocities (m/s), and the pressure in each node (m).

The model is run for: (a) its peak-hour demand condition, to check for the possible value of the pressure of the minimum system; and (b) its minimum demand condition, to check for the value of the possible maximum pressure in the network.

Step 7: Examination of Hydraulic Run Results

Usually, all possible hydraulic parameters can be shown from the computer run results. Of these parameters, the designer must examine two important results very closely: (a) The low system pressure points that are below the 7 m pressure and the affected nodes, and (b) the pipes that have high head loss per km in excess of the 10 m/1,000 m pipeline criteria.

The designer must also examine the balancing flows of the reservoir and analyze if the reservoir discharge or inflow is reasonable for its storage size.

Step 8: Adjusting Assumed Parameters of the Elements:

Based on the results of the computer simulation, the designer will improve

the network model by adjusting the pipe and node data for specific elements,

particularly for those that did not meet the design criteria. For example, for pipes

that have high resulting head losses, the designer will have to increase the pipe

size to the next larger diameter. If there is a system pressure that is below 7 m,

the designer could replace some of the pipes leading to the affected node with

a larger diameter. The height of the reservoir could be adjusted if needed to

achieve a good system pressure.

The adjusted model is run again in the software. After the run, the results are examined and the model readjusted. The above cycle is repeated until an acceptable hydraulic model is achieved.

Step 9: Finalizing the Network Configuration

The model is subjected to repeated simulation and data adjustments until an

acceptable network configuration is reached.

1.7.3 Pipeline Design Criteria

The pipeline should be designed to withstand the following;

- Internal test pressure of water,

- Water hammer (positive surge),

- Vacuum and negative surge,

- External pressures when laid below ground (overburden and surcharge),

- Conveyance water temperature (thermoplastic pipes),

- Maximum working temperature (ferrous pipe coatings),

- Temperature stresses when laid above ground,

- Flexural stresses when laid over supports, constructed at intervals or on bridges,

- Longitudinal stresses due to flow at tees, tapers and bends,

- Foundation reaction depending upon the nature of support,

- Handling stresses,

For flexible pipes (thermoplastic and steel) the following criteria should be met;

- The pipe deflection (out-or-roundness) must not exceed the allowable limit;

- The combined stress or stain in the pipe wall must not exceed the allowable limit, and

- The factor of safety against buckling must be adequate;

For semi-rigid pipes (ductile iron) the following criteria should be met:

- The pipe deflection (out-or-roundness) should not exceed the allowable limit;

- The pipe wall bending stress should not exceed the allowable limit.

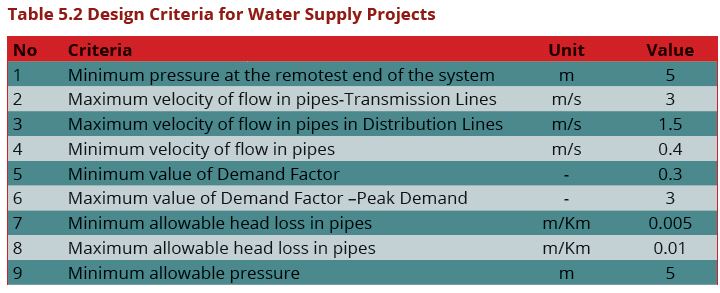

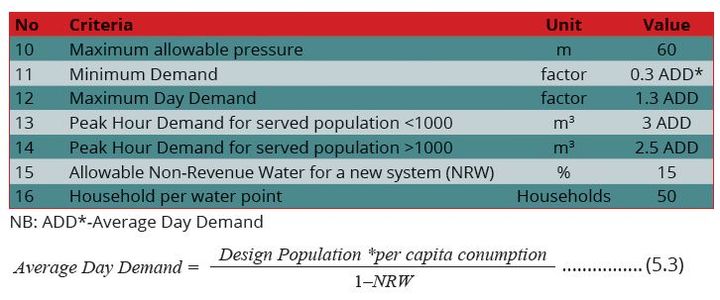

The distribution pipelines should be designed to handle the peak hour demand of the system under the following criteria;

1.8 Pipeline Materials Selection

1.8.1 Considerations in Selecting Pipeline Materials

1.8.1.1 Flow Characteristics

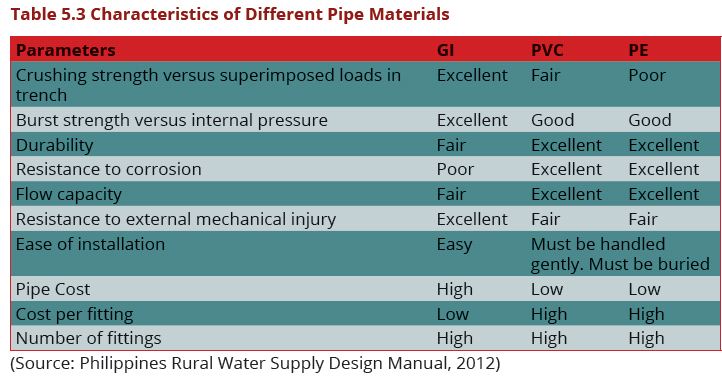

The friction head loss is dependent on the flow characteristics of pipes. Friction loss is a power loss and thus may affect the operating costs of the system if a pump is used.

1.8.1.2 Pipe Strength

Select the pipe with a working pressure and bursting pressure rating adequate to meet the operating conditions of the system. Standard water pipes are satisfactory usually only in low pressure water supply systems.

1.8.1.3 Durability

Select the type of pipe with good life expectancy given the operating conditions and the soil conditions of the system. It should have an expected life of 30 years or more.

1.8.1.4 Type of Soil

Select the type of pipe that is suited to the type of soil in the area under consideration. For instance, acidic soil can easily corrode G.I. pipes and very rocky soil can damage plastic pipes unless they are properly bedded in sand or other type of material.

1.8.1.5 Availability

Select locally manufactured and/or fabricated pipes whenever available.

1.8.1.6 Cost of Pipes

Aside from the initial cost of pipes, the cost of installation should be considered. This is affected by the type of joint (such as screwed, solvent weld, slip joint, fussion welding etc.), weight of pipe (for ease of handling), depth of bury required, and width of trench and depth of cover required.

1.8.2 Types of Pipe Materials Available

1.8.2.1 Galvanized Iron (GI) Pipes

GI pipes are available in sizes of 13, 19, 25, 31, 38, 50, 63 and 75 mm and in lengths of 6 m. They are joined by means of threaded couplings.

Advantages

- Strong against internal and external pressure.

- Can be laid below or above ground.

- People in rural areas know how to install these kind of pipes.

Disadvantages

- GI Pipes can easily be corroded, thus the service life is short.

- These have rougher internal surface compared to plastic pipes, hence, have higher friction head losses.

1.8.2.2 Plastic Pipes

Polyvinyl Chloride (PVC) and Polyethylene (PE) are commercial plastic pipes. They are available in different pressure ratings and sizes of 13, 19, 25, 31, 38, 50, 63, 75, 100 up to 200 mm. PVC is supplied in lengths of 3 m and 6 m while PE is available in rolls and, for diameters greater than 100 mm, in straight lengths. Suppliers have to be consulted with respect to the pressure ratings to be used. PE pipes are joined by butt-welding. PVC pipes can be joined either through solvent cement welding or through the use of special sockets with rubber rings.

Advantages

- Smooth internal surface.

- Resistant to corrosion.

- Extremely light and easy to handle.

- Do not form encrustation

Disadvantages

- Lose strength at high temperatures (500° C+),

- Not suitable for laying above the ground,

- Can deform during storage,

- Require good and carefully prepared bedding materials,

- Rubber rings can be eaten by some termites if appropriate pipes lubricant is not used in jointing. Thus, the use of edible oil should be avoided.

- When joints of fusion welding is opted for, local expertise is scarce.

1.9 Appurtenances For Transmission And Distribution Mains

Pipe fittings are those specially manufactured fittings used to facilitate changes in direction, changes in diameter, the making of branches etc. to the pipeline. Further, fittings are needed to install valves, meters and other mechanical devices and to allow for the change from one pipe material to another or diameter changes.

1.9.1 Valves

One of the most important types of appurtenances is the valve. A valve is a device that can be opened and closed to different extents (called throttling) to vary its resistance to flow, thereby controlling the movement of water through a pipeline. Valves can be classified into five general categories as follows:

1.9.1.1 Isolation Valves

Perhaps the most common valve in the water distribution system is the isolation valve, which can be manually closed to block the flow of water. Isolation valves include gate valves (the most popular type), butterfly valves, globe valves, and plug valves.

1.9.1.2 Check Valves

Check valves, also called directional valves, are used to ensure that water can flow only in one direction through a pipeline.

1.9.1.3 Float Valves

Many water utilities employ devices called float valves at the point where a pipeline enters a tank. When tank level rises to a specified upper limit, the valve closes to prevent any further flow from entering, thus eliminating overflow.

1.9.1.4 Air Release Valves

These valves are provided in system high points, where trapped air settles, and at changes in grade, where pressures are most likely to drop below ambient or atmospheric conditions.

1.9.1.5 Pressure Reducing Valves

Pressure reducing valves (PRVs) throttle automatically to prevent the downstream hydraulic grade from exceeding a set value and are used in situations where high downstream pressures could cause damage.

1.9.1.6 Washout valves

To be provided at the lowest points for the purpose of flushing the pipeline.

1.9.2 Fittings

Fittings are installed in the pipelines for the following purposes;

- To connect the same type and size of pipe - Union: Unions are provided in the pipeline for ease of repair. Unions are usually installed at 60-meters intervals on straight pipelines. Coupling: Used in joining 2 pipes of the same diameter. It is cheaper than unions.

- To connect two pipes of different sizes- Reducers are used when there is a reduction of pipe size and include bushes and elbows for galvanized iron pipes. Also available are reducing elbows, tees and crosses.

- To change the direction of flow - Elbow; to divide the flow into two - Tee; to divide the flow into three - Cross.

- To stop the flow - caps, plugs and blind flanges.

REFERENCES

MoW 3rd Edition Design Manual, 2009

Philipines Rural Water Supply Design Manual, 2012

Previous Page: Chapter_Four:_Water_Demand_Assessment << >> Next Page: Chapter_Six:_Pumping_Systems