Difference between revisions of "Chapter Ten: Pumping Machinery"

| Line 1,067: | Line 1,067: | ||

Table 10. 10: A Sample Repair Works Report Sheet | Table 10. 10: A Sample Repair Works Report Sheet | ||

| − | [[File:10. | + | [[File:10.10i.png|700px|center]] |

==== Variables Influencing Performance of Solar Water Pumping (SWP) ==== | ==== Variables Influencing Performance of Solar Water Pumping (SWP) ==== | ||

Latest revision as of 13:28, 20 July 2022

Contents

- 1 Chapter Ten: Pumping Machinery

1 Chapter Ten: Pumping Machinery

1.1 General

Pumping machinery and pumping stations are very important components in water supply and sanitation projects. Pumping machinery is subject to wear, tear, erosion and corrosion due to the nature of their functioning and therefore is vulnerable to failure. Generally, more numbers of failures or interruptions in water supply and sanitation projects are attributed to pumping machinery than any other component. Therefore, correct operation and timely maintenance and upkeep of pumping stations and pumping machinery are both of vital importance to ensure continued existence of uninterrupted water supply and sanitation services. Sudden failures can be avoided by timely inspection, follow up actions during observations of inspection and planned periodic maintenance. Downtime can be reduced by maintaining an inventory of the fast moving spare parts. Efficiency of pumping machinery decreases due to normal wear and tear. Timely action for restoration of efficiency can keep energy bills within a reasonable optimum limit. In case there is no standby pump provision, suitable water pumps with identical duty shall be provided as 100% standby in case of a single pump set and two or more pumps with a minimum of 50% standby along with all necessary accessories like cables, control panels, safety equipment, valves and fittings. Providing a minimum of 50% standby pump set will help in operating the schemes in initial stages until stabilization is achieved.

In case of depletion of sources during dry season or rains failure, the design engineer should ensure that schemes can be operated partially without throttling of pumps. While replacement of motors/ pumps is done, it must be insisted to provide star rated motors to have energy savings. Generally, as the pumps are scheme specific, (i.e. discharge & head fixed depending upon the requirements), the question of standardization with regard to minimizing the inventory does not arise. To ensure better performance/effective cost savings, energy audit and water and sanitation audit needs to be done for every project.

Annual monitoring of handed over projects must be done by the department that implemented the projects. Proper record keeping is also very important. A log book should be maintained covering the following items:

(a) Timings when the pumps are started, operated and stopped during 24 hours,

(b) Voltage in all three phases,

(c) Current drawn by each pump-motor set and total current drawn at the installation,

(d) Frequency,

(e) Readings of vacuum and pressure gauges,

(f) Motor winding temperature,

(g) Bearing temperature for pump and motor,

(h) Water level in intake/sump,

(i) Flow meter reading,

(j) Daily Power factor over 24 hours duration, and

(k) Any specific problem or event in the pumping installation or pumping system (e.g. burst in pipeline, tripping or fault, power failure).

1.2 Components of a Pumping Station

The components of a pumping station can be grouped into three groups as follows:

(a) Pumping machinery

Pumps and other mechanical equipment, i.e. valves, pipe works, vacuum pumps, motors, switchgears, cables, transformers and other electrical accessories.

(b) Ancillary Equipment

(i) Lifting equipment,

(ii) Water hammer control device,

(iii) Flow meters,

(iv) Diesel generating set.

(c) Pumping stations

(i) Sump/intake/well/tube well/borehole,

(ii) Pump house,

(iii) Screens,

(iv) Penstock/gate.

1.2.1 Type of Pumps

The following types of pumps are used in water supply and sanitation systems:

(a) Centrifugal pumps,

(b) Vertical turbine pumps,

(c) Oil lubricated,

(d) Self-water (pumped water) lubricated,

(e) Clear water lubricated,

(f) Submersible pumps,

(g) Vertical bore well type pump-motor set,

(h) Mono bloc open well type pump-motor set,

(i) Jet pumps,

(j) Reciprocating pumps.

1.2.2 Important Points for Operation of the Pumps

Various types of pumps are in use and the specification of O&M schedule provided by the manufacturers shall be followed. However, the following points shall be observed while operating the pumps:

(a) Dry running of the pumps should be avoided,

(b) Centrifugal pumps have to be primed before starting,

(c) Pumps should be operated only within the recommended range of the head-discharge (duty) characteristics of the pump,

(d) If a pump is operated at a point away from the designated duty point, the pump efficiency normally reduces,

(e) Operation near the shut off point should be avoided, as the operation near the shut off causes substantial recirculation within the pump, resulting in overheating of water in the casing and consequently, overheating of the pump,

(f) Voltage during operation of pump-motor set should be within ± 10% of the rated voltage. Similarly, current should be below the rated current as per specification of the name plate on the motor,

(g) Whether the delivery valve should be opened or closed at the time of starting should be decided by examining the shape of the power-discharge characteristics of the pump. Pumps of low and medium specific speeds draw lesser power at shut off head and power required increases from shut off to a normal operating point. Hence in order to reduce the starting load on the motor, a pump of low or medium specific speed is started against closed delivery valve. Normally the pumps used in water supply schemes are of low or medium specific speeds. Hence, such pumps need to be started against closed delivery valves. The pumps of high specific speed draw more power at shut off. Such pumps should be started with the delivery valves open,

(h) The delivery valve should be operated gradually to avoid sudden change in flow velocity which can cause water hammer pressures. It is also necessary to control the opening of the delivery valves during pipeline - filling period so that the head on the pump is within its operating range to avoid operation on low head and consequent overloading. This is particularly important during charging of the pumping mains initially or after shutdown. As the head increases, the valve shall be gradually opened,

(i) When the pumps are to be operated in parallel, the pumps should be started and stopped with a time lag between the two pumps to restrict change of flow velocity to a minimum and to restrict the dip in voltage in the incoming feeder. The time lag should be adequate to allow stabilizing the head on the pump, as indicated by a pressure gauge,

(j) When the pumps are to be operated in series, they should be started and stopped sequentially, but with minimum time lag. Any pump, next in sequence should be started immediately after the delivery valve of the previous pump is even partly opened. Due care should be taken to keep the air vent of the pump next in sequence open, before starting that pump,

(k) The stuffing box should let a drip of leakage to ensure that no air is passing into the pump and that the packing is getting adequate water for cooling and lubrication. When the stuffing box is grease sealed, adequate refill of the grease should be maintained,

(l) The running of the duty pumps and the standby one should be scheduled carefully so that no pump remains idle for a long period and all pumps are in ready-to run condition. Similarly, unequal running should be ensured so that all pumps do not wear equally and become due for overhaul simultaneously. If any undue vibration or noise is noticed, the pump should be stopped immediately and causes of the vibration or noise be checked and rectified,

(m) By-pass valves of all reflux valves, sluice valves and butterfly valves shall be kept in the closed position during normal operation of the pumps,

(n) Frequent starting and stopping should be avoided because, each start causes overloading of the motor, starter and contactors. Though overloading lasts for a few seconds, it reduces the lifetime of the equipment.

1.2.2.1 Undesirable Operations

The following undesirable operations should be avoided:

(a) Operation at Higher Head-The pump should never be operated at a head higher than the maximum recommended. Such operation results in excessive recirculation in the pump, overheating of the water and the pump. Another problem, which arises if a pump is operated at a head higher than the recommended maximum head, is that the radial reaction on the pump shaft than the recommended maximum head, is that the radial reaction on the pump shaft increases causing excessive unbalanced forces on the shaft which may cause failure of the pump shaft. As a useful guide, appropriate marking on pressure gauge be made. Such operation is also inefficient as pump efficiency at higher head is normally low,

(b) Operation at Lower Head-If pump is operated at lower head than recommended minimum head, radial reaction on the pump shaft increases causing excessive unbalanced forces on the shaft which may cause failure of the pump shaft. As a useful guide, appropriate markings on both the pressure gauge and the ammeter should be made. Such operation is also inefficient as efficiency at lower heads is normally low,

(c) Operation on higher suction lift. If a pump is operated on a higher suction lift than the permissible value, pressure at the eye of the impeller and the suction side falls below the vapour pressure. This results in convention of water into vapour. These vapour bubbles during passage collapse resulting in cavitation if the pump, pitting on the suction side of the impeller and casing as well as excessive vibrations. In addition to mechanical damage due to pitting, discharge of the pump also reduces drastically,

(d) Throttled operation-At times if the motor is continuously overloaded, the delivery valve is throttled to increase the head on the pump and to reduce power drawn from the motor. Such operation results in inefficient running as energy is wasted in throttling. In such cases, it is preferable to reduce the diameter of the impeller which will reduce the power drawn from the motor. Installation of variable voltage & variable frequency (VVVF) drive as a remedial measure is recommended,

(e) Operation with strainer/foot valve clogged-If the strainer or foot valve is clogged, the friction loss in the strainer increases to high magnitudes which may result in pressure at the eye of the impeller falling below water vapour pressure, causing cavitation and pitting similar to operation at a higher suction lift. The strainers and foot valves should be periodically cleaned, particularly during the rainy season,

(f) Operation with occurrence of Vortices-If vibration continues even after taking all precautions, vortex may be the cause. All parameters necessary for ensuring vortex-free operation should be checked.

1.2.2.2 Starting the Pumps

The following points should be checked before starting the pump:

(a) Power is available in all 3 phases,

(b) All connections are properly thimbled,

(c) Trip circuit for relays is in a healthy state,

(d) Check voltage in all 3 phases,

(e) The voltage in all phases should be almost the same and within ± 10% of the rated voltage, as per permissible voltage variation,

(f) Check functioning of the lubrication system specifically for oil lubricated and clear water lubricated vertical turbine pumps and oil lubricated bearings,

(g) Check stuffing box to ensure that it is packed properly,

(h) Check and ensure that the pump is free to rotate,

(i) Check over current setting if the pump is not operated for a week or longer periods,

(j) Before starting, it shall be ensured that the water level in the sump/intake is above the low water level and inflow from the source or preceding pumping station is adequate.

1.2.2.3 Stopping the Pump

(a) Stopping the Pump under Normal Condition

Steps to be followed for stopping a pump of low or medium specific speed are as follows:

(i) Close the delivery valve gradually (sudden or fast closing should not be resorted to which can give rise to water hammer pressures),

(ii) Switch off the motor,

(iii) Open the air vent in case of Vertical Turbine (VT) and submersible pump,

(iv) Stop lubricating oil or clear water supply in case of oil lubricated or clear water lubricated VT pump as applicable.

(b) Stopping after Power Failure/Tripping

If power supply to the pumping station fails or trips, actions stated below should be immediately taken to ensure that the pumps do not restart automatically on resumption of power supply. Though no-volt release or under volt relay is provided in the starter and the circuit breaker, possibility of its malfunctioning and failure to open the circuit cannot be ruled out. In such eventuality, if the pumps starts automatically on resumption of power supply, there will be sudden increase in flow velocity in the pumping main causing sudden rise in pressure due to the water hammer which may prove disastrous to the pumping main. Secondly, due to sudden acceleration of flow in the pumping main from no-flow situation, acceleration head will be very high and the pumps shall operate near the shut off region during the acceleration period which may last for a few minutes for long pumping mains and cause overheating of the pump. Restarting of all pumps simultaneously shall also cause overloading of the electrical system. Hence, precautions are necessary to prevent auto-restarting on resumption of power.

Following procedure should be followed:

(i) Close all delivery valves on delivery piping of the pumps if necessary, manually as actuators cannot be operated due to non-availability of power,

(ii) Check and ensure that all circuit breakers and starters are in the open condition i.e. off-position,

(iii) All switches and circuit breakers shall be operated to open i.e. off-position,

(iv) Open the air vent in case of a vertical turbine or submersible pump and close the lubricating oil or clear water supply in case of oil lubricated or clear water lubricated vertical turbine pump. Information about power failure should be given to all concerned, particularly to the upstream pumping stations to stop pumping so as to prevent overflow.

1.3 Pumping Machinery Maintenance

(a) Daily

• Clean the pump, motor and other accessories,

• Check coupling bushes/rubber spider,

• Check stuffing box, gland, etc.

(i) Routine observations of irregularities

The pump operator should be watchful and should take appropriate action on any irregularity noticed in the operation of the pumps. Particular attention should be paid to following irregularities:

• Changes in the sound of a running pump and motor,

• Abrupt changes in bearing temperature,

• Oil leakage from the bearings,

• Leakage from the stuffing box or mechanical seal,

• Changes in voltage,

• Changes in current,

• Changes in vacuum gauge and pressure gauge readings,

• Sparks or leakage current in motor, starter, switch-gears, cable, etc.,

• Overheating of the motor, starter, switch gear, cable, etc.

(ii) Record of operations and observations

A log book should be maintained to record the observations, which should cover the following items:

• Timings when the pumps are started, operated and stopped during 24 hours,

• Voltage in all three phases,

• Current drawn by each pump-motor set and total current drawn at the installation,

• Frequency,

• Readings of vacuum and pressure gauges,

• Motor winding temperature,

• Bearing temperature for the pump(s) and motors,

• Water level in the intake/sump,

• Flow meter reading,

• Daily Power Factor (PF) over 24 hour’s duration,

• Any specific problem or event in the pumping installation or pumping system (e.g. burst in pipeline, tripping or fault, power failure),

(b) Monthly Maintenance

(i) Check free movement of the gland of the stuffing box; check gland packing and replace if necessary. Clean and apply oil to the gland bolts.

(ii) Inspect the mechanical seal for wear and replacement if necessary. Check condition of bearing oil and replace or top up if necessary.

(c) Quarterly Maintenance

(i) Check alignment of the pump and the drive. The pump and motor shall be decoupled while correcting alignment, and both the pump and motor shafts shall be pushed to either side to eliminate effect of end play in bearings.

(ii) Clean oil lubricated bearings and replenish with fresh oil. If bearings are grease lubricated, the condition of the grease should be checked and replaced/replenished to the correct quantity. An anti-friction bearing should have its housing so packed with grease that the void space in the bearing housing should be between one third to half. A fully packed housing will overheat the bearings and will result in reduction of life of the bearings.

(iii) Tighten the foundation bolts and holding down bolts of the pump and motor mounting on the base plate or frame.

(iv) Check vibration level with instruments if available; otherwise by observation.

(v) Clean flow indicator, other instruments and appurtenances in the pump house.

(d) Annual Inspections and Maintenance

A very thorough, critical inspection and maintenance should be performed by trained operators/engineers once in a year. Following items should be specifically attended:

(i) Clean and flush bearings with kerosene and examine for flaws that may have developed if any, e.g. corrosion, wear and scratches. Check end play. Immediately after cleaning, the bearings should be coated with oil or grease to prevent ingress of dirt or moisture,

(ii) Clean bearing housing and examine for flaws, e.g. wear, grooving etc. Change oil or grease in the bearing housing,

(iii) Examine shaft sleeves for wear or scour and necessary rectifications. If shaft sleeves are not used, shaft at gland packing’s should be examined for wear,

(iv) Check stuffing box, glands, lantern ring, and mechanical seal and rectify if necessary,

(v) Check clearances in the wearing ring,

(vi) Check impeller hubs and vane tips for any pitting or erosion,

(vii) Check interior of volute, casing and diffuser for pitting, erosion, and rough surface,

(viii) All vital instruments i.e. pressure gauge, vacuum gauge, ammeter, voltmeter,

(ix) Undertake performance test of the pump for discharge, head efficiency.

1.3.1 Maintenance Schedule for Motors

(a) Daily

(i) Clean the external surface of the motor,

(ii) Examine earth connections and motor leads,

(iii) Check temperature of the motor and check whether overheated. The permissible maximum temperature is above the level which can be comfortably felt by hand. Hence, temperature observation should be taken with a Resistance Temperature Detector (RTD) or a thermometer. (Note: In order to avoid opening up motors, a good practice is to observe the stator temperature under normal working conditions. Any increase not accounted for, by seasonal increase in ambient temperature, should be suspected),

(iv) In case of oil ring lubricated bearings,

(v) Examine bearings to check whether oil rings are working,

(vi) Note bearing temperature,

(vii) Add oil if necessary,

(viii) Check for any abnormal bearing noise,

(ix) Note pump vibration if any.

(b) Monthly

(i) Check belt tension. In case where this is excessive it should immediately be reduced,

(ii) Blow dust from the motor,

(iii) Examine oil in oil lubricated bearings for contamination by dust, grit. (This can be judged from the colour of the oil),

(iv) Check functioning and connections of anti-condensation heater (space heater),

(v) Check insulation resistance.

(c) Quarterly

(i) Clean oil lubricated bearings and replenishes fresh oil. If bearings are grease lubricated, the condition of the grease should be checked and replaced/replenished to correct quantity,

(ii) Anti-friction bearings should have its housing so packed with grease that the void space in the bearing housing should be between one third to half. A fully packed housing will overheat the bearing and will result in reduction of life of the bearing,

(iii) Wipe brush holders and check contact faces of brushes of slip-ring motors. If contact face is not smooth or is irregular, file it for proper and full contact over slip rings,

(iv) Check the insulation resistance of the motor,

(v) Check tightness of the cable gland, lug and connecting bolts,

(vi) Check and tighten foundation bolts and holding down bolts between motor and the frame,

(vii) Check vibration level with instrument if available; otherwise by observation.

(d) Half Yearly

(i) Clean winding of the motor, bake and varnish if necessary,

(ii) In case of slip ring motors, check slip-rings for grooving or unusual wear, and polish with smooth polish paper if necessary.

(e) Annual Inspections and Maintenance

(i) Clean and flush bearings with kerosene and examine for flaws that may have developed, if any, e.g. wear and scratches. Check end-play. Immediately after cleaning, the bearings should be coated with oil or grease to prevent ingress of dirt or moisture,

(ii) Clean bearing housing and examine for flaws, e.g. wear, grooving etc. Change oil or grease in bearing housing,

(iii) Blow out dust from the windings of motors thoroughly with clean dry air. Make sure that the pressure is not so high as to damage the insulation,

(iv) Clean and varnish dirty and oily windings. Re-varnish motors subjected to severe operating and environmental conditions e.g., operation in dust-laden environment, polluted atmosphere, etc.,

(v) Check condition of the stator, stamping, insulation, terminal box, fan, etc.,

(vi) Check insulation resistance to earth and between phases of motor windings, control gear and wiring,

(vii) Check air gaps,

(viii) Check resistance of earth connections.

1.3.2 History Sheet

Similar to the history sheet of the pump, history sheet of the motor should be maintained. The history sheet should contain all important particulars, records of periodic maintenance, repairs, inspections and tests. It shall generally include the following:

(a) Details of motor, rating, model, class of duty, class of insulation, efficiency curve, type test result and type test certificate, etc.,

(b) Date of installation and commissioning,

(c) Addresses of manufacturer & dealer with phone & fax number and e-mail addresses,

(d) Brief details of monthly, quarterly, half yearly and annual maintenance and observations of inspections about insulation level, air gap, etc.,

(e) Details of breakdown, repairs with fault diagnosis,

(f) Running hours at the time of any major repairs.

1.3.3 Low Voltage Starters, Circuit Breakers and Panel

Note: Circuit diagram of the starter/breaker should be pasted on the door of the switch gear and additional copy should be kept on record.

(a) Daily

(i) Clean the external surface,

(ii) Check for any spark or leakage current,

(iii) Check for overheating.

(b) Monthly

(i) Blow the dust and clean internal components in the panel, and breaker,

(ii) Check and tighten all connections of cables, wires, jumpers and bus-bars. All carbon deposits shall be cleaned,

(iii) Check relay setting.

(c) Quarterly

(i) Check all connections as per circuit diagram,

(ii) Check fixed and moving contacts and clean with smooth polish paper, if necessary,

(iii) Check oil level and condition of oil in the oil tank. Replace the oil if carbon deposit in suspension is observed or the colour is black,

(iv) Check insulation resistances,

(v) Check conditions of insulators.

(d) Yearly

(i) Check and carry out servicing of all components, thoroughly clean and reassemble, (ii) Calibrate voltmeter, ammeter, frequency meter, etc.

1.3.4 High voltage Breakers Contactors and Protection relays

Note: Circuit diagram of the breaker/relay circuit should be pasted on the door of switch gear and additional copy should be kept on record. Maintenance schedule specified for Low voltage breakers are also applicable to High voltage breakers and contactors. In addition, the following important points shall be attended for High voltage breakers and contactors.

(a) Monthly

(i) Check spring charging mechanism and manual cranking arrangement for operation,

(ii) Clean all exposed insulators,

(iii) Check trip circuit and alarm circuit,

(iv) Check opening & closing timing of the breaker.

(b) Quarterly

(i) Check control circuits including connections in marshalling boxes of breakers and the transformer,

(ii) Check oil level in Minimum/Low Oil Circuit Breaker (M/LOCB)/High Voltage Oil Circuit Breaker (HV.OCB) and top up with tested oil,

(iii) Yearly / Two yearly testing of protection relay with Direct Current (D.C) injection shall be carried out once in year,

(iv) Servicing of High voltage breaker and contactor shall be carried out once in 2-3 years,

(v) Check dielectric strength of oil in the breaker and replace if necessary,

(vi) Check male & female contacts for any pitting and measure contact resistance.

1.3.5 Transformer and Transformer Substation

Maintenance schedule as follows shall be applicable for transformer and sub-station equipment e.g. lightning arrestor, Air Break (AB) switch, Drop Off (DO) or horn gap fuse, sub-station earthing system. This section is particularly useful for the large schemes. Instructions of district/region/zone electricity department and chief electrical inspector shall be followed.

(a) Daily Observations and Maintenance

(i) Check winding temperature and oil temperature in the transformer and record. (For large transformers above 1000 kV, the temperature should be recorded hourly),

(ii) Check leakages through current/potential transformer unit, transformer tank and High/Low voltage bushings,

(iii) Check colour of silica gel. If silica gel is of pink colour, change the same by spare charge and reactivate old charge for re-use.

(b) Monthly

(i) Check oil level in the transformer tank and top up if required,

(ii) Check relay contacts, cable termination, connections in marshalling box,

(iii) Check operation of AB switch and DO fuse assembly,

(iv) Clean radiators free from dust and scales,

(v) Pour 3-4 buckets (6 to 8 buckets in hot season) of water in earth pit. Watering shall be increased to once in a week in hot seasons. Watering shall be increased to once in a week in hot seasons. Shall preferably contain small amounts of salt in solution,

(vi) Inspect lightning arrestor and High/Low voltage bushing for cracks and dirt.

(c) Quarterly

(i) Check dielectric strength of transformer oil and change or filter if necessary.

(ii) Check insulation resistance of all equipment in the sub-station, continuity of earthings and earth leads,

(iii) Check operation of tap changing switches.

1.3.6 Pre-rain and Post-rain Checks and Maintenance

- Check insulation resistance of the transformer,

- Test transformer oil for dielectric strength, sludge etc. If necessary, filtration of oil shall be carried out before the rainy season,

- Oil shall be tested for dielectric strength after rainy season.

(a) Half-Yearly

(i) Check dielectric strength of transformer oil in current/potential transformer and filter or change oil if necessary,

(ii) Check contact faces of Air Break (AB) switch and Drop Out/Horn Gap fuse; apply petroleum jelly or grease to moving components of AB switch.

(b) Annual

(i) Measure resistance of earth pit. Resistance shall not exceed 1 ohm,

(ii) Check bus bar connections, clean contact faces, change rusted nut bolts,

(iii) Calibrate the protection relay for functioning. Check relay setting and correct if necessary,

(iv) Ensure that the sub-station area is not water-logged. If required, necessary earth fillings with metal spreading at the top shall be carried out once in a year. Check drainage arrangement to prevent water logging in sub-station area and cable trenches,

(v) Test transformer oil for acidity test.

(c) Special Maintenance

(i) Painting of transformer tank and steel structure of the sub-station equipment shall be carried out after every two years,

(ii) The core of the transformer and winding shall be checked after 5 years for the transformer up to 3,000 kVA and after 7–10 years for transformers of higher capacity.

1.4 Operation and Maintenance Activities of Selected Pumps

1.4.1 Submersible Pumps

The operation and maintenance of submersible pumps are given below in Appendix 5 illustrates the details of troubleshooting for these pumps.

1.4.1.1 Operations

1.4.1.2 Inspection procedure for key Components

- Submersible pumps may be operated manually with a switch located above ground level or automatically with a pressure switch, electrodes or float control devices,

- Submersible pumps should always be operated below the water level,

- The pump should be installed higher than the well screen to prevent pump break suction which my lead to a burned pump motor.

Inspection procedure for key Components

The installation of a new pump brings with it the expectation that it will operate consistently. Most operators are content with starting a pump and observing it run, like that is enough to see that the pump is operational. It is very vital to inspect the pump immediately on start-up, and also to do frequent inspections on it. Inspections assist in picking up faults early, when they occur before they become catastrophic. Routine preventive maintenance inspections can help address possible issues before they become major (or even catastrophic) events.

In most cases, four major components should be inspected in submersible pumps:

• Alarm monitoring,

• Pressure flow checks,

• Visual Inspection:

o Inspect for clogging debris on suction inlet,

o Check pump exterior for dents, corrosion and abrasion,

o Clean off.

• Corrosion:

Inspect valve threads.

Below is an inspection checklist for submersible borehole pumps:

• Check electrical condition of insulation on power cable(s) and on all phases of the motor,

• Check for any loose or faulty electrical connections within the control panel,

• Measure resistance between stator windings (in ohms),

• Check voltage supply between all phases of the electrical control panel,

• Check voltage balance (Vac) between all phases on the load side of the pump / mixer control panel with pump / mixer running,

• Check amperage draw on all phases of the motor (in amps),

• Check condition and operation of the motor thermal protection control system (if equipped),

• Remove pump / mixer from the lift station for physical inspection,

• Check condition of upper and lower shaft seals (inspect condition of motor / stator housing, if applicable),

• Check condition and operation of leakage and bearing sensors (if equipped),

• Check for worn out or loose impeller or propeller,

• Check impeller wear rings (rotating & stationary),

• Check for any unusual noise in the upper and lower bearings,

• Clean, reset and check operation of the level control system (if equipped),

• Check for physical damage of power and control cables,

• Check for correct shaft rotation,

• Check operation of valves and the associated equipment.

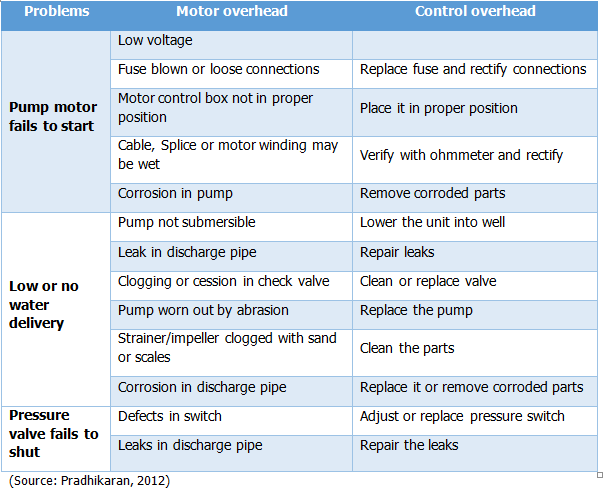

Table 10.1 summarizes the common problems of submersible pumps and their remedies.

Table 10. 1: Common Troubleshooting for Submersible Pumps

1.4.1.3 Maintenance and Repair

To begin a maintenance job analysis, the assigned person needs the following information:

(a) Pump motor unit size and type;

(b) Static and pumping water level of the well;

(c) Size of drop pipe and/or drop cable;

(d) Pump setting;

(e) Discharge pressure required;

(f) Capacity pumped;

(g) Line voltage; and

(h) Operating Manual.

1.4.2 Centrifugal Pumps

1.4.2.1 Operations

To operate a centrifugal pump, certain procedures need to be followed, which are found in the manual supplied by the manufacturer. They generally involve the steps outlined below:

1.4.2.2 Steps in Operating the Centrifugal Pumps

(a) Before starting the motor, make sure that the discharge gate valve is closed;

(b) If the pump is not self-priming or has defective suction line or foot valve, add priming water. Priming displaces the air in the suction line or drop pipe of the pump with water;

(c) Allow the pressure to build up, and then slowly open the discharge valve. Doing this slowly avoids water hammer, which could destroy the pipes and valves;

(d) Start the pump motor;

(e) After the pressure has built up, slowly open the discharge gate valve. In case the pump has been primed with water, waste the water pumped during the first 1-2 minutes by opening the drain valve;

(f) Make a routine check for faults in the operation of the system (abnormal noise, vibration, heat, and odour).

1.4.2.3 Maintenance and Repair

Bearings, gears and other pump moving parts should be lubricated on a regular schedule, using the lubricants recommended by the supplier. The following are specific actions to remedy centrifugal pump problems:

(a) Low Pump Efficiency

If the pump performance tests reveal that the pump is operating at significantly lowered efficiencies, the pump should be pulled out, inspected and repaired or reconditioned. This work is best referred for servicing to the manufacturer or a pump repair specialist.

(b) Packing Adjustment

The water flowing through the stuffing box should be maintained at a level just enough to prevent overheating. The gland nuts should be loosened or tightened one-quarter turn only to allow the packing to equalize against the pressure.

(c) Checking and Adjusting Misaligned Head Shaft

Pump vibrations could indicate a misalignment of the head shaft. This can be checked by the following procedure:

(i) Remove the motor dust cover, motor head nut and key, and take out the motor drive flange.

(ii) Check if the head shaft is concentric with the motor hollow shaft bore.

(iii) If needed, adjust by using shims.

Other common problems and their remedies are summarized in Appendix 6.

1.4.3 Jet pumps

1.4.3.1 Operations

Jet pumps can be operated manually or automatically with a pressure switch, electrodes or a float control switch.

1.4.3.2 Operating the Non-Self-Priming Jet Pump

(a) Initially inspect the assembly. Make sure that the power supply to the motor is off;

(b) Check lubrication. Make sure that the pump rotates fully by manually turning the shaft. (For more details, refer to the pump manual);

(c) Remove pressure gauge bushing and prime pump with clean water. Never start the motor until the pump has been filled with water;

(d) Replace pressure gauge bushing and close the discharge gate valve;

(e) Start the pump motor. Note build-up of pressure in the pressure gauge. Open the discharge valve slowly;

(f) If discharge pressure is lost and fails to build up again after a short time, the system still contains air. Stop the pump motor and repeat operating procedures starting from item #3. It may be necessary to repeat the procedure several times until the system is completely filled with water.

1.4.3.3 Operating the Self-Priming Pump

Routinely inspect the assembly. Make sure power supply to motor is off.

1.4.3.4 Maintenance of Jet Pumps

The manufacturer or equipment supplier always provides the client with the Operation and Maintenance manual upon purchase of their product. Refer to this manual for the proper operation and maintenance of the pump. The matrix for centrifugal pumps may be also used as a guide for troubleshooting operational problems of jet pumps. Additional troubleshooting information for jet pump problems is presented in Appendix 7.

1.4.4 Vertical Turbine Pumps

(a) Pumps should be properly primed before starting,

(b) Air vent to be fully opened before starting,

(c) Correct rotation of the pump,

(d) Pump should not be operated, if ratchet pins are missing,

(e) Bowl assembly is completely submerged.

1.4.4.1 Inventory of Materials for Submersible, Centrifugal and Vertical Turbine Pumps

The following is the list of fast moving materials for Submersible, Centrifugal, and Vertical Turbine Pumps:

(a) Submersible pumps: Impellers

(b) Centrifugal pumps: Impellers, diffusers, bearings, gland packing’s

(c) Vertical turbine pumps: thrust bearings, gland packing, head shaft, intermediate shaft, bearing spider, bowl assemble, impeller.

(d) Motors: Bearings

(e) Moulded Case Circuit Breaker (MCCB), Relay, tripping circuit, fuses.

(f) Transformer: Oil

1.4.5 Hand Pumps

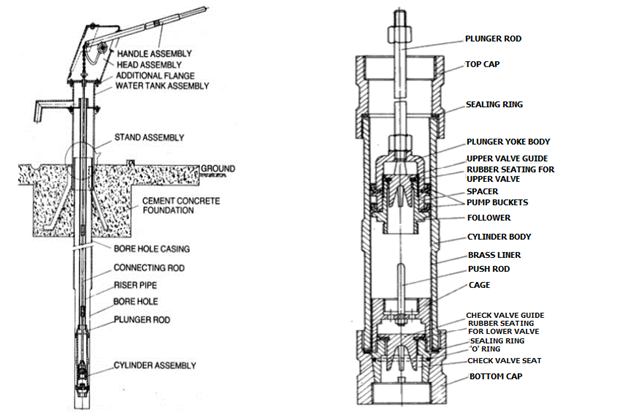

Figures 10.1 illustrate the typical types of hand pumps. The maintenance of a hand pump is identified in two categories.

1.4.5.1 Minor Repairs

The repairing of hand pump which does not require lifting of hand pump assembly is treated as minor repair. The minor repairs of a hand pump may be made by a semi-skilled care taker/CBWSOs). This type of repairing involves replacement of handle nut & bolts, repairing of chain, bearing. Appendix 8 illustrates the troubleshooting of Hand pumps.

1.4.5.2 Major Repair

The repairing of a hand pump which involves pulling out and cleaning of the hand pump assembly is treated as a major repair; this type of repairing can be carried out by hand pump specialist from RUWASA or the water supply and sanitation utility.

The daily, monthly and annual activities should include the following O&M activities:

(a) Weekly

(i) Check the fittings such as nuts, bolts and handle assembly and tighten them,

(ii) Check the axle bolt and tighten as needed,

(iii) Make sure the lock nut is tight,

(iv) Make sure the hand pump is firm on its base,

(v) Check the flange bolts fastening the water chamber to the pedestal are tight,

(vi) Testing water quality using a Field Test Kit.

Figure 10. 1: India Mark II (left) and Cylinder Assembly of India Mark III Hand Pump (Right)

(Source: India Operational and Maintenance Manual 2013).

(b) Monthly Activities

(i) Tighten the handle axle nut and lock nut,

(ii) Check for loose or missing flange bolts and nuts and tighten as needed,

(iii) Open the cover and clean inside the pump,

(iv) Check the chain anchor bolt for proper position and tighten if needed,

(v) Verify whether hand pump is firm on its base and fix it if needed,

(vi) Open the cover and clean inside the pump,

(vii) Verify rusty patches, clean with a wire brush and apply anticorrosive paint,

(viii) Check for loose or missing flange bolts and nuts and tighten as needed,

(ix) Check the chain anchor bolt for proper position and tighten if needed,

(x) Look for rusty patches, clean with a wire brush and apply anticorrosive paint,

(xi) Find out whether the hand pump base is loose and arrange for repair of the foundation as needed,

(xii) Measure the static water level,

(xiii) Grease all components.

(c) Annual Activities

(i) Verify the discharge of water,

(ii) Verify the handle position and repair if needed,

(iii) Verify whether guide bush, roller chain is not excessively worn out and replace if needed,

(iv) Verify whether Discharge is satisfactory,

(v) Verify whether Handle is shaky,

(vi) Verify whether Guide bush is excessively worn out,

(vii) Verify whether Chain is worn out,

(viii) Verify whether Roller chain guide is excessively worn out,

(ix) Discharge is satisfactory,

(x) Check all parts of the hand pump for wear and tear / damages, replace damaged parts and reassemble the hand pump,

(xi) Measure the well depth,

(xii) All the components of the hand pump to be checked for wear and tear/damages and damaged parts replaced and hand pump re-assembled,

(xiii) Washing and cleaning of the components of the hand pumps should be done with water and bleaching powder, if required instead of mixture of water and kerosene,

(xiv) The repairs to the hand pump platforms to be done as and when needed and need not be on daily basis.

1.4.5.3 Disassembly, Inspection and Reassembly of Hand Pump

1.4.5.3.1 Disassembly

Disassembly of the hand pump may be required from time to time if major problems are faced as follows:

(a) Loose pump head cover bolt,

(b) Remove inspection cover from head assembly,

(c) Insert chain coupling supporting tool,

(d) Lift the handle to the top position and disconnect chain from handle by removing the “nylon” nut and bolt (i.e., nylon insert lock nut),

(e) Take out handle axle; while removing use the handle axle punch to protect the axle thread and remove the handle from the head assembly,

(f) Remove flange bolts from the head assembly,

(g) Remove head assembly from the water tank,

(h) Place the connecting rod vice on to the water chamber top flange and tighten vice against connecting rod and allow the head assembly to sit on the connecting rod vice,

(i) Disconnect the chain assembly from connecting rod,

(j) Support connecting rod with connecting rod lifter, loosen connecting rod vice and remove; gently lower connecting rod to sit on check valve; remove connecting rod lifter,

(k) Loose water tank nuts and bolts and remove water tank bottom flange bolts,

(l) Lift water tank by using tank pipe lifter and lifting spanners,

(m) Fit self-locking clamp and remove water tank,

(n) Join plunger assembly to check valve by turning the rod lifter in clock wise direction,

(o) To take out water from the pipe, remove the rod lifter; join the rod lifting adaptor to the connecting rod; place head assembly over water tank and fix handle to the lifter

(p) Remove water from riser pipe by pushing down handle suddenly,

(q) Lift handle upwards slowly and disconnect connecting rod lifting adapter and take out head assembly,

(r) Tighten the connecting rod lifter to the connecting rod and lift the connecting rod and fix the connecting rod vice,

(s) Hold the connecting rod, slowly loosen the rod vice and lift the connecting rod; tighten the vice and repeat the process until it is possible to remove the connecting rod; repeat the process until the last connecting rod with plunger and check valve is pulled out,

(t) Separate the check valve from the plunger,

(u) Unscrew the plunger from the check valve,

(v) Remove all the parts of the check valves and clean them.

1.4.5.3.2 Inspection

Inspection for reassembly covers the following:

(a) Check the water tank for leakage or damage,

(b) Wash and clean all parts with a mixture of water and bleaching powder,

(c) The stand assembly should be on a perfect level – check with a spirit level,

(d) Check the coupler for broken threads,

(e) Check flanges and spout pipe for cracks and leakage,

(f) Check the handle axle, bearings and chain; apply grease to the bearings and chain.

1.4.5.3.3 Reassembling

Reassembling involves the following:

(a) Ensure parts are clean and dry, and moving parts are lubricated with oil and grease,

(b) Check ‘O’ ring and cup seal and replace as needed,

(c) Remove cover of casing pipe for fixing stand assembly,

(d) Place stand assembly over casing pipe and make sure that it is vertical and check level of flange by spirit level,

(e) Fix water tank assembly on the stand flange by tightening the nuts and bolts,

(f) Join the check valve and plunger,

(g) Connect the plunger to the connecting rod,

(h) Insert the plunger assembly connected with the check valve in the riser pipe and connect the riser coupler to the water tank,

(i) Insert the lower end of the connecting rod in the riser pipe, and place the connecting rod over the water tank and fix it to the vice,

(j) Join the connecting rod pieces as per the requirement and insert in the riser pipe,

(k) Remove the connecting rod vice from the water tank by holding the top end of the connecting rod,

(l) Fix the connecting rod lifter to the top end of the connecting rod and rotate in the direction of the arrow so as to separate the check valve from the plunger and ensure that it reaches the bottom plate,

(m) Make a mark by hack saw on the connecting rod at the level of the water tank,

(n) Lift the connecting rod assembly, fix the connecting rod vice and tighten the connecting rod,

(o) Cut the connecting rod as per the marking after removing the connecting rod lifter,

(p) Smoothen with the help of a file the cut surface of the connecting rod,

(q) Make necessary threads on the top most end of the connecting rod,

(r) Fix the middle flange on the top of the water tank and ensure that all four corners coincide,

(s) Tighten the check nut at the top of the connecting rod,

(t) Screw the chain on to the connecting rod,

(u) Place the chain coupling supporting tool on the middle flange and remove the rod vice,

(v) Place the middle flange and set flanges with water tank,

(w) Place head assembly over the middle flange and tighten by spanner,

(x) Place handle assembly and insert the handle axle by handle axle punch,

(y) Lift the handle for fixing chain and tighten chain anchor bolt and nylon nut fully (i.e., nylon insert lock nut); remove chain coupler supporting tool by lowering the handle,

(z) Lift handle up and apply grease on the chain,

(aa) Lower down the handle and fix inspection cover and tighten the cover bolt fully by the crank spanner.

1.5 Operation and Maintenance of Solar Systems

1.5.1 Solar system

General

After the system has been installed and commissioned, focus shifts to O&M throughout its lifetime. System operation can be optimized by closely monitoring and recording key system parameters (data logging), enabling operators to assess system performance or demand changes.

One crucial aspect of maintenance is warranties, usually against defective components or poor workman-ship. Under the defects liability period of 1 to 2 years, any items that fail, are not installed to standard, or are damaged by natural calamities must be corrected on site at cost to the contractor/supplier/ installer.

Component usual warranty period

Solar panels 25 years,

Pump/motor 2-5 years,

Inverter 5-10 years,

Remaining components 1-2 years.

During the warranty period, the supplier is also expected to check system components and perform preventive maintenance at least quarterly (in any case, neither pumps nor panels require heavy maintenance, with panels only needing periodic cleaning) to attend to user complaints within a reasonable period of time, and to resolve any system breakdowns within 3 days. In addition to component warranties, the supplier may also provide a performance warranty on the system as a whole, ensuring that it will meet or exceed the design performance for a number of years.

Sustainability of Solar Water Pumping (SWP) has been a challenge in many countries and especially in rural areas, with systems failing often within a short time after commissioning due to lack of proper O&M. It is therefore increasingly common for communities to establish comprehensive maintenance contracts with suppliers during warranty periods, and it is a good practice to extend such contracts beyond the warranty period. Suppliers should further secure system sustainability by training system operators, namely on basic plumbing skills useful for repairing leakages in the pipe network and in handling the advanced inverters and sensors common in modern solar pumping systems. The rural water supplies audit (URT, 2018b) recommended introduction of such capacity building programme in identified zonal centres of RUWASA.

Since solar panels have no moving parts that could be affected by rust or break down, solar power requires very limited maintenance, other than regular dusting. Cleaning the solar panels with water is recommended to remove any dirt or dust.

Operation and Maintenance Guidelines

Solar PV pumping systems are characterized by their simplicity, unattended operation, and low maintenance requirements compared to conventional systems. Except for the pump itself, there are no moving parts that would require periodic maintenance and incur additional costs every time maintenance is performed.

In the case of battery usage for energy storage, which is not recommended, maintenance and battery replacement would be required every three to four years on average. There are some modern batteries that can live up to 8 years but are still considered expensive and would require very delicate preventive maintenance that might not be present in typical solar PV pumping applications (mainly in rural and remote regions).

For the other components, the PV modules are considered sturdy and strong enough to withstand harsh environmental conditions coming with a warranty of 10 years, an expected lifetime of more than 25 years, and normally an efficiency maintenance guarantee that ensures efficiency drop doesn’t exceed 20% over the period of 25 years. The pump normally lives for more than 8 years and can reach 14 years if well maintained. Usually it is sold with a 2 year-warranty and spare part availability. Other than that, only occasional inspection and regular maintenance is required, at no cost, to make sure the system is doing fine and avoid losses due to dust or other residues sticking to the panel. It is essential to properly operate and maintain the pumping system to achieve high efficiency and reliable operations.

Operation Guidelines

(a) The pump should be switched off when not in operation;

(b) The pump should never run dry. It is critical to make sure the suction is primed before turning on the surface pump;

(c) The pump should be properly mounted and fixed on the base-plate to withstand vibrations and avoid unwanted noise that could also reduce the lifetime of the pump;

(d) The pump should be used daily for at least 15 minutes to avoid problems;

(e) Pump should be covered adequately for weather protection. In a pump pit adequate air venting system (passive or active) should be in place;

(f) The surface pump should be kept away from water at all times;

(g) The pump should not be switched on and off too often. There should be at least 15 seconds between a switch off and a switch on;

(h) Foot-valve should be of minimum 2” (50 mm) size so as to minimize suction losses;

(i) Sharp bends should be avoided in the pipelines to avoid unnecessary pressure drops;

(j) Delivery and suction pipelines should be air-tight;

(k) In case of thunders and strong wind, panels should be kept in the zero-tilt position (applicable only for tracking systems);

(l) The cover of the main junction box should not be left open;

(m) No loose wires should be un-insulated.

Regular Maintenance

Monthly

• Panel Cleaning: Clean the panels regularly to avoid particles, leaves, and other residues from blocking the sun. Panels can be cleaned with a plain piece of cloth with some water when available;

• Panel Inspection: Inspect the PV panels to make sure there are no cracks or damages.

Biannual

• Shadow Prevention: Check the panels for any shadow and perform necessary trimming of trees if necessary;

• Wiring inspection: Check wires regularly for fraying, splitting, or damage.

Annual

• Valves Inspection: Check and clean the foot-valve,

• Electrical Components Check: Check switches, fuse, wiring, junction box and connections.

Biennial

• Pump Inspection: For surface pumps, carbon brushes need to be checked and replaced every two years.

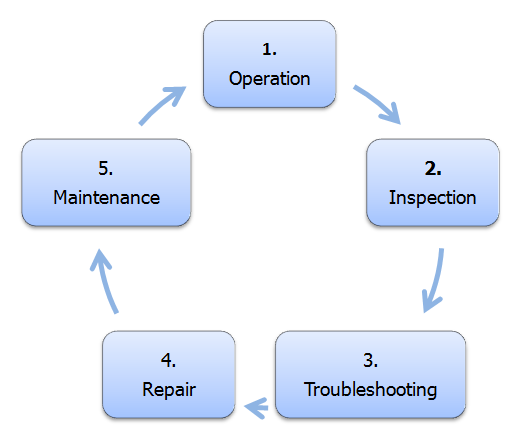

Figure 10. 2: Operation and Maintenance Cycle for Solar Water Pumping

1.5.2 Inspection

Every system regardless of the type, must be inspected periodically. It is an important aspect for good operation of the system. System inspection should be conducted at least once a year depending on the size and intricacies of the system. Planned inspection, prompt timely maintenance and in some cases inspection and maintenance can be carried simultaneously especially when the inspectors also double up as maintainers. It is also highly recommended that the inspectors also triple as repair experts of the system.

Inspection procedure for key Components:

Solar panels

(a) Check the solar panels for dirt and cracks,

(i) Dirt accumulates on the solar panels over time, as they are exposed to the environment. Cracks may be due to vandalism or heavy hailstorms.

(ii) If there are cracks on the panels, one should consider replacing those panels

(iii) Dirt can be cleaned off the surface using clean water and a cloth. Soap should not be applied.

(b) Electrical cables

(i) Check to see if all electrical cables are still intact, loose cables should be tightened up.

(c) Tilt Angle

(i) In fixed solar arrays this may not be necessary, unless there is suspicion of tilt on angle if inclined. This should be corrected, to avoid dust accumulation on flatter inclines, and reduced solar absorption on steeper inclines.

1.5.3 Inspection Checklist

Inspection checklist gives guidance and easiness to the operator to do inspection. It saves times and increases accuracy as it includes all important elements to be checked. Appendix 9 presents the solar arrays and accessories inspection checklist.

1.5.4 Paperwork

In all inspections the importance of paperwork and record keeping cannot be over emphasized. It is prudent upon every inspector to keep and maintain a good record of the system, as this will form a major part of maintenance decision making.

Table 10. 2: A Sample Record Status of the System

| Item Description | Available | Not Available | Comments |

|---|---|---|---|

| Operation and maintenance manual for system on site or available | |||

| Service record for system on site or available | |||

| Flow diagram and sequence of operation on site or available | |||

| Photographs taken and placed in service record | |||

| This inspection record filed in service record |

1.5.5 Troubleshooting a Solar Powered Water Supply System

This section of the manual contains information that may be used to determine what is wrong with a solar powered water supply system. Troubleshooting techniques have also been explored. Troubleshooting a Solar Powered Water Supply System should involve more than looking for an obvious problem, or replacing components at random in an attempt to get the system working again. This is particularly true of Solar Powered Water Supply Systems. What is required is a systematic procedure that carefully “troubleshoots” the system until the problem is located and remedied.

Cause or Symptom What may appear to be the cause of a problem may actually be a symptom of another problem. For example, if a pump is not pumping water, you can replace a pump while the problem is the electric cable that supplies current and voltage to the pump. Replacing the pump, will not solve the problem but result in wasting money and time for a simple problem. Never assume that a system is completely without faults after correcting a problem. Spend a few more minutes observing and inspecting the system. This will save time doing a return job. Or even a bigger job caused by an escalated problem which could have been spotted during the first visit.

Recommended troubleshooting

Good troubleshooters follow the below listed steps or a variation of them. The steps include:

(a) Planning:

(i) Planning takes off with brainstorming the possible causes of the problem,

(ii) This includes the tools and materials used to diagnose the fault,

(iii) It also includes the resources to be allocated for finding and fixing the fault, such as money, time and labour.

(b) Cause /Source finding:

(i) This is the investigation /diagnosis phase,

(ii) Start with checks that will have low impact on the system,

(iii) Proceed in a systematic, organized and logical manner,

(iv) Isolate the results of testing to the component being tested,

(v) Sometimes the only way to determine if a component is working properly or not is to replace it and see what happens. Remember that this may fix the symptom but it can fail to turn up the real cause of a problem.

(c) Repairing:

(i) Repairs can be made on a “quick fix/temporary repair” basis, doing as little as possible to get the system running again,

(ii) Another approach is to replace major portions of the system to be absolutely certain the problem is gone,

(iii) The correct approach is to determine what is the real cause of the problem is, and make repairs that solve that problem so that it does not happen again. Whether to repair or replace defective components depends on the cost and availability of the component,

(iv) Generally, the more expensive and difficult it is to obtain something, the more appropriate the repair of the component,

(v) If the part is cheap and readily available, it generally will be replaced,

(vi) If repairs can be made to the defective component, it can become the new replacement the next time this same component fails in this or other systems.

(d) Testing:

(i) After the cause of the problem has been identified and corrected, inspect and test the entire system,

(ii) This confirms that the new components are working, and that no other problems exist,

(iii) The defective components should be tested as well. The best time is usually before rebuilding. As an example, if a control works fine on a test bench, but not at all at the site, a problem exists at the site that will not let the new control work there either,

(iv) If the part is truly defective, look for the reason it failed. For example, did the pump control unit get wet? Will the new control unit also get wet and fail?

(e) Recording:

(i) The last part of troubleshooting is record-keeping,

(ii) Maintenance and repair records are kept to maintain a history of each system.

Troubleshooting records should be part of that written history. In addition, writing down the troubleshooting process preserves that information for the person who found the problem.

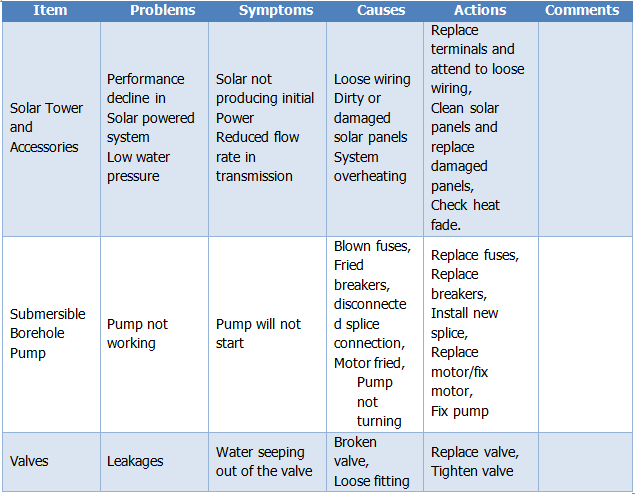

Table 10. 3: Troubleshooting Chart

1.5.6 Repair Works

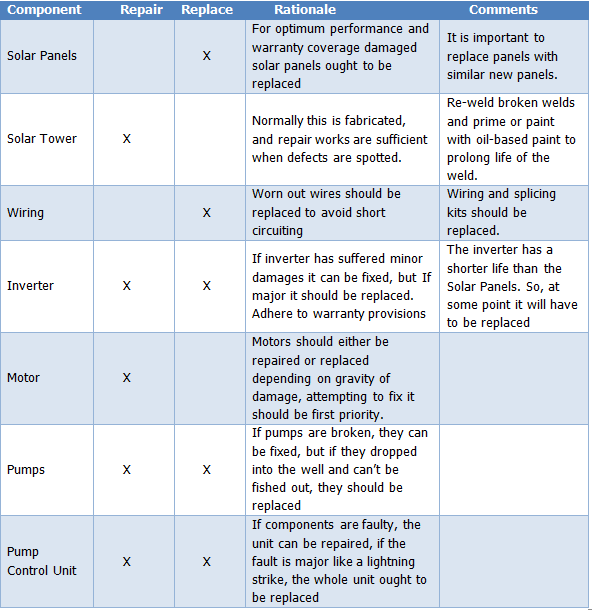

This section includes information on the repair or replacement of solar powered potable water supply system components. The first section lists common components and whether to repair or replace them. Then, specific procedures for particular components are described. The section ends with a sample repair record sheet. During repair works, one normally asks questions of whether to repair or replace. Some components, such as Solar Panels, can never be repaired, and must be replaced. Others, such as mounting racks and supporting steels, are usually repaired rather than replaced. However, most components can be repaired/replaced. In general, the decision to repair or replace is based on:

• Availability of replacement parts,

• Lead time for replacement parts,

• Cost of replacement parts,

• difficulty of repair.

Table 10. 4: Repair or Replace Choice Table

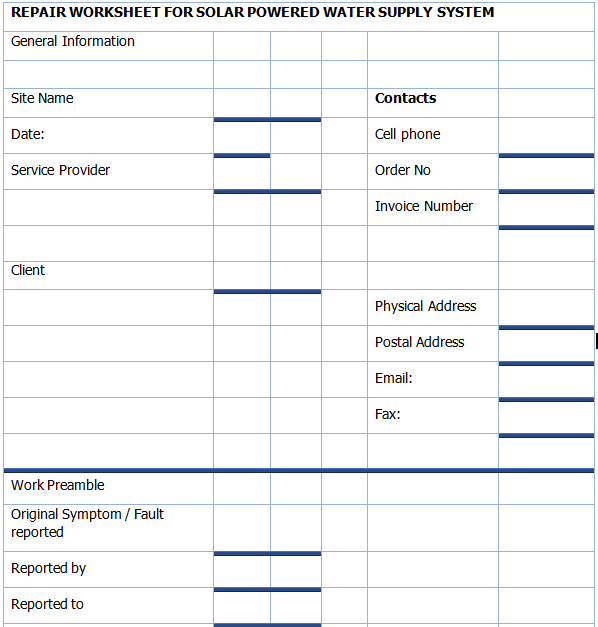

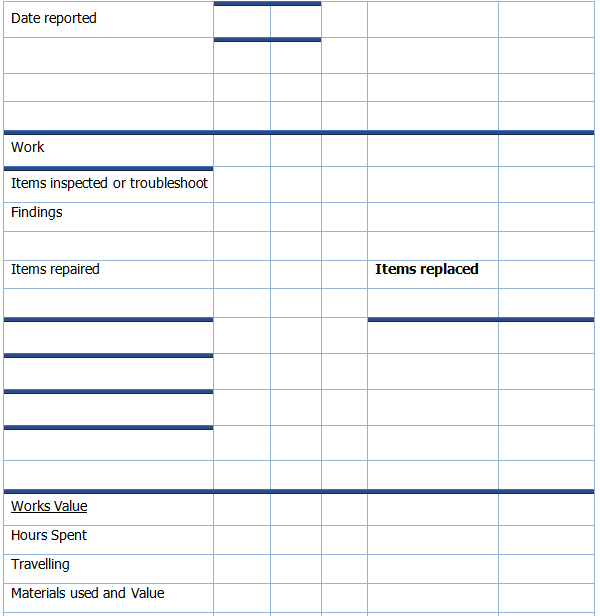

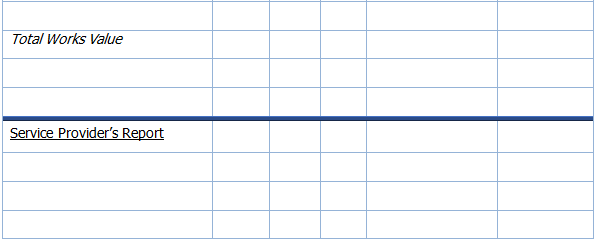

Table 10.5 presents a typical repair worksheet.

Table 10. 5: Repair Worksheet

1.5.7 Maintenance

This is the most important section; it answers the question of how can the system be kept working. To the layman, it is perceived as the only section that ought to be given attention and disregard all the other sections. It cannot be over-emphasized how important preventive maintenance can be. It involves a great deal of pro-activeness. Every system ought to have a regular maintenance schedule that is appraisable. Some information on minor repairs is given; however, if major repairs are necessary, use repair information in Section 10.5.6. If a system has not been maintained, or has not been operational for some time, it is suggested to perform a system inspection, using Section 10.5.2, and to make necessary repairs before starting a regular schedule of maintenance.

Maintenance procedures

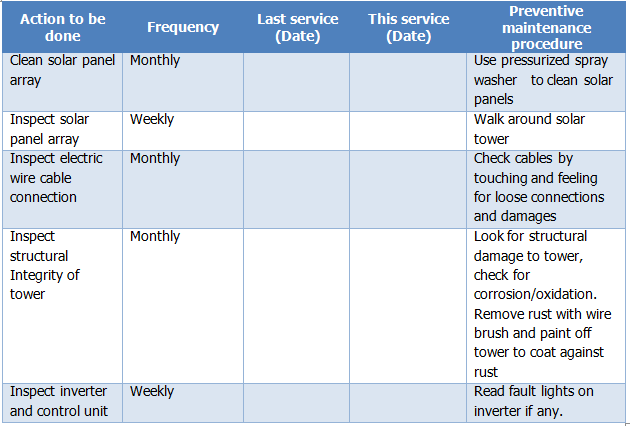

Preventive Maintenance activities are the core element of the maintenance services to a reticulated solar powered potable water supply system. It comprises regular visual and physical inspections, as well as verification activities with a specific task periodicity of all key components which are necessary to comply with the operating manuals and recommendations issued by the Original Equipment Manufacturers (OEMs). It must also maintain the equipment and component warranties in place and reduce the probability of failure or degradation. This maintenance will be carried out at predetermined intervals or according to the prescribed OEM manuals. These are included in a detailed Annual Maintenance Plan (AMP) which provides an established time schedule with a specific number of iterations for carrying out the maintenance. Tables 10.6 - 10.10 gives some of the tools that can be used.

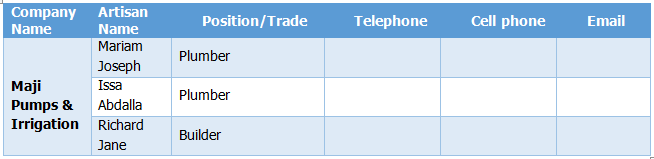

Table 10. 6: Example of Maintenance Contact List

The maintenance contact list (Table 10.6) is easy to use at local level as it only outlines contacts of responsible maintenance team. As such it can be used by the water system users committee for further details of maintenance.

Equipment manufacturer's manuals

The equipment manufacturer’s manuals shall and will be attached in this section. The manuals should be used by the operations/maintenance team as reference. Preventive maintenance can be scheduled periodically from weekly to monthly and annually. Tables 10.7 - 10.10 outline the steps to be taken and tools used in performing preventive maintenance exercises.

Wire control kit

Recommended daily operational duties/preventive maintenance Based on the layout and operation of the system, several parameters for inspection and action were developed and set to respond to routine challenges of the system. Some of these actions to be performed can be categorized as daily, weekly, monthly and annually:

The weekly preventive maintenance has been skipped because it is similar to the daily tasks.

Preventive maintenance logbook

All maintenance activities should be written down on a maintenance log book or log sheet. The logbook as Table 10.7 should be used to keep records of the maintenance on the system.

Table 10. 7: Preventive Maintenance Logbook

Ensuring security of the system may require conducting an assessment of the security within the system. Table 10.8 can be used to do such an assessment check.

Table 10. 8: Security Assessment

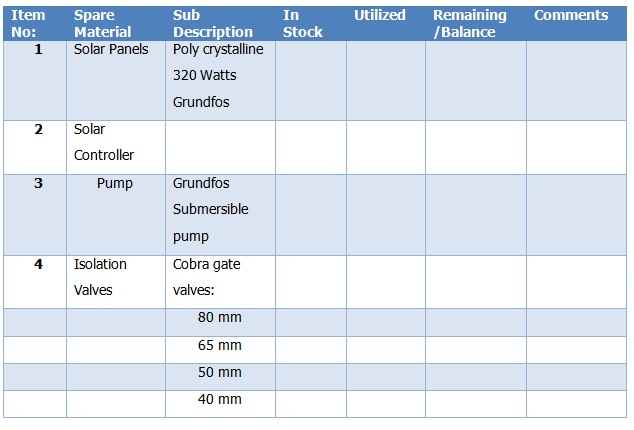

Spare Parts Management

Spare Parts Management is an inherent and substantial part of O&M. it shall be used throughout the lifespan of the system. Table 10.9 is the tool that will be used to record available spares for the system by the maintenance team. From the water sales, 10 percent of the revenue generated from the system shall be kept as a reserve to purchase the spare parts. The major components like pumps, solar panel array, solar controller, water meter can be insured for damage and vandalism and this is elaborated in the risk management section of volume III of the DCOM Manual.

Table 10. 9: Spare Material Management List

Operators notes

This section of the manual is intended for the use of the project (Water System Operator) who is in charge of operating the potable water supply project to guide them through the tasks of the Operator. It gives explanations of the facility structure and then explains the tasks of the operators, and things to bear in mind when operating facilities. It also provides in part, troubleshooting information.

Operator’s duties

The operator is the key person in the operation of the system. He has important roles that he/she has to execute on a daily basis. The roles encompass the following:

• Operate the system properly or as designed,

• Patrol and inspect the system daily and weekly,

• To write the operation records, this consists of operational data,

• To correspond with the Maintenance In-charge/Project Coordinator,

• Be a link between the customers and the Maintenance In-charge/Project Coordinator,

• Collect and collate issues from the customers.

The sustainability of the system hinges mainly on the management aptitude of the operator. The operator is expected to safeguard the system and keep all records of the system operation.

Detailed regular operational duties for the water operator:

Solar Panel Array

• Inspect cable wiring interconnecting solar panels,

• Inspect inverter,

• Inspect dirt /dust accumulation on solar panels,

• Inspect structural integrity of solar panels tower.

Water Control Unit and pump

• Check control unit for fault reporting,

• Observe sound and performance of submersible pump,

• Inspect pump for leaks,

• Observe water meter and record readings off it.

Maintenance tools

Maintenance tools should be kept inside the kiosk house and locked. A tool inventory should be conducted every month to establish the condition of the tools and also establish any lost tools. The plumbers should pay for lost tools. The tools should be used in maintaining the water project and should not be used for any other work outside the project. This practice prolongs the tool lifespan. Generally, tools should be used for the job they were designed for, wrong tools should not be used for any job.

Reporting and communication

Reports are major sources of the information. In implementing the projects, reports are a pre-requisite in order to know the implementation status and make a rational decision timely if the need arises. Operator needs to record the operational status of the system daily. The data will form a part of the project O&M monthly report. When faults are detected, it should be communicated to the Maintenance In-charge immediately. The Maintenance In-charge then coordinates repair work, depending on the type of repair required.

The steps below outline the communication chronology in the project:

• The water customers or water operator discover or notice a breakdown in the water supply system,

• They notify the Maintenance In-charge/Project Coordinator swiftly,

• The water operator requests for repair of the system,

• The water operator notifies the Maintenance In-charge/Project Coordinator of the parts that are required to repair the breakdown,

• The Maintenance In-charge/Project Coordinator avails funds for fixing the breakdown,

• The Maintenance In-charge/Project Coordinator procures the materials needed to attend to the breakdown,

• The Maintenance In-charge/Project Coordinator provides spare parts to the plumber to expedite repairs,

• The plumber then expedites works on the repairs,

• The plumber then prepares and submits a repair report to the Maintenance In-charge/Project Coordinator,

• The Maintenance In-charge/Project Coordinator avails money and pays the plumber for the repairs,

• The system is back to operation again.

Repair manual

In this section of the O&M manual, discussion will be based on repair procedures for certain components of the water system.

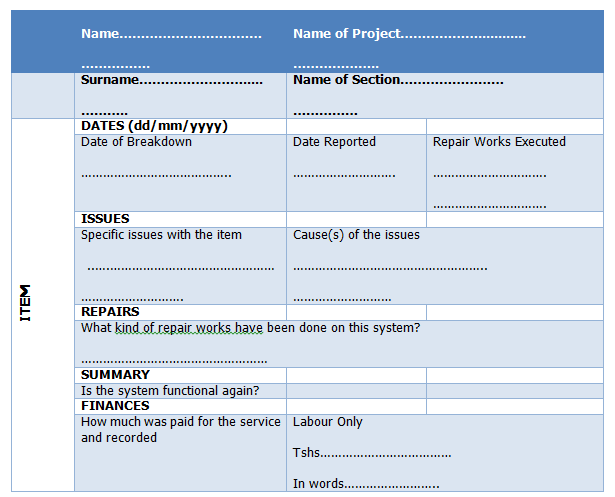

Sample repair works record or report sheet

Table 10.10 is a sample of a record sheet on any repair works that ought to be done on the system. It is very important to know the name of the technical person who attended to the fault. Date on which the fault was attended. The location of the repair is also important in order for the operators to pick up trends if any, on fault re occurrences.

Table 10. 10: A Sample Repair Works Report Sheet

1.5.8 Variables Influencing Performance of Solar Water Pumping (SWP)

The simplified SWP algorithm presented for understanding the sizing dynamics is good for static design conditions. In reality, there are several input variables that are not constant and thus affect SWP performance over the number of the years. To be rigorous, sizing algorithms must evaluate the conditions over the course of a whole year to determine when the limiting design conditions occur. Below are some of the key variables:

(a) Seasonal changes in solar radiation. Essentially, SWP water output is more or less proportional to the irradiation. First-pass sizing is usually based on average insolation for the year, or perhaps the worst month of the year. It is necessary to assess the output for days when radiation will be less than the annual average, and less than the monthly average. Tilt angle optimization is required;

(b) Seasonal changes in pumping head. Similarly, drops in water levels will affect pump output. Water output is more or less indirectly proportionate to the pumping head. Too conservative an estimation of water level will result in system over-sizing;

(c) Sunny versus cloudy days. Average insolation is insufficient. A key variable is the amount of cloud cover and intermittency of the sunshine. Especially, variable speed drives coupled with AC pumps tend to suffer degraded performance under stop-start solar conditions, since they require minimum power conditions start-up, and take considerable time to spool up once threshold levels are reached. So while 2 days might have the same amount of cumulative insolation, a clear morning with zero sun in the afternoon is likely to yield far higher water output than an intermittently cloudy day. Derating for this kind of local variability is important for certain motor pump types in particular;

(d) Seasonal changes in water demand. Experience shows that demand is not constant throughout the year. For human consumption, the variations are low (25%), but for livestock and irrigation the variations can be significant, up to 80%, with zero demand in very wet seasons. The analysis of these variables can be cumbersome.

Previous Page: Chapter Nine: Distribution System << >> Next Page: Chapter Eleven: Audit and Conservation of Energy