Chapter Sixteen: Water Meters, Instrumentation Telemetry and Scada

Contents

1 CHAPTER SIXTEEN :WATER METERS, INSTRUMENTATION TELEMETRY AND SCADA

1.1 Water Meters

A water meter is a scientific instrument for measurement of the quantity of water distributed to the consumers or sewage pumped. In Tanzania, water meters are used to measure the volume of water used by residential, institutional, industrial, as well as commercial buildings and public water points/kiosks that are supplied with water by a public water supply system. Water meters can also be used at the water source, and throughout a water system to determine flow through that portion of the system. Water meters can be used to measure wastewater quantities. Water meters measure flow in cubic metres (m3) on a mechanical or electronic register. Some electronic meter registers can display rate-of-flow in addition to total usage. A water meter also fulfils the need to know accurately the water produced and distributed. Water meter is always specified in two accuracies i.e. lower range and upper range accuracies. The upper range and lower range accuracies are 2% and 5% of the actual quantity respectively for the water meter.

Water meters having sizes from 15 mm to 50 mm as per TBS standards are considered to be Domestic water meters and sizes from 50 mm and above as per TBS are considered to be Bulk water meters. There are different types of water meters such as mechanical water meter, electro-mechanical, ultra-sonic water meters. However, prepaid water meters are highly recommended nowadays for domestic as well as public water points that operate as kiosks. Public water points can have one or more taps.

1.1.1 Sizing of Water Meters

In general the sizing of water meters is done according to the guidelines given in TZS 782-5: 2015- ISO 4064-5: 2014, the main considerations on the characteristics of the water flow and quality have to be known, before a suitable meter type with the right specifications can be chosen to fulfil this task. These are as follows:

(a) Water meter has to be selected according to the flow to be measured and not necessarily to suit a certain size of water supply mains,

(b) The maximum flow shall not exceed the maximum flow rating,

(c) The nominal flow shall not be greater than the nominal flow rating,

(d) The minimum flow to be measured shall be within the minimum starting flow of the meter,

(e) Low head loss, long operating flow range, less bulky and robust meter shall be preferred.

1.1.2 Installation of Ordinary Water Meters

In order to ensure proper working of the meters, TBS has given guidelines in TZS 782-5: ISO: 4064-5:2015 for their installation as per the drawing given in it. The following guidelines should be borne in mind while installing the meters:

(a) Assure accuracy of water meter on a meter test bench at minimum and permanent flow rates before installation,

(b) The water meter being a delicate instrument shall be handled with great care. Rough handling including jerks or fall is likely to damage it and affects its accuracy,

(c) The meter shall be installed at a spot where it is readily accessible. To avoid damages and over run of the meter due to intermittent water supply system, it is always advisable to install the meter, so that the top of the meter is below the level of the communication pipes so that meters always contain water, when there is no supply in the line. Also, the minimum straight length condition as per the drawing shall be observed,

(d) The meter shall preferably be housed in a chamber with a lid for protection; it should never be buried underground nor installed in the open nor under a water tap so that water may not directly fall on the meter. It should be installed inside inspection pits, built out of bricks or concrete and covered with lid. It should not be suspended,

(e) The meter shall be so installed that the longitudinal axis is horizontal and the flow of water should be in the direction shown by the arrow cast on the body,

(f) Before connecting the meter to the water pipe, it should be thoroughly cleaned by installing in the place of the water meter a pipe of suitable length and diameter and letting the passage of a fair amount of water flow through the pipe work to avoid formation of air pockets. It is advisable that the level of the pipeline where the meter is proposed to be installed should be checked by a spirit level,

(g) Before fitting the meter to the pipeline, check the union’s nuts in the tail pieces and then insert the washers. Thereafter, screw the tail pieces on the pipes and install the meter in between the nuts by screwing. In order to avoid its rotation during the operation, the meter should be kept fixed with suitable non-metallic clamps. Care should be taken that the washer does not obstruct the inlet and outlet flow of water,

(h) The protective lid should normally be kept closed and should be opened only for reading the dial,

(i) The meter shall not run with free discharge to atmosphere. Some resistance should be given in the down side of the meter if static pressure on the main exceeds 10 m head,

(j) A meter shall be located where it is not liable to get severe shock of water hammer which might break the system of the meter,

(k) Owing to the fine clearance in the working parts of the meters they are not suitable for measuring water containing sand or similar foreign matter and in such cases a filter or dirt box of adequate effective area shall be fitted on the upstream side of the meter. It should be noted that the normal strainer fitted inside a meter is not a filter and does not prevent the entry of small particles, such as sand,

(l) In case of intermittent water supply to SR and schemes with storage at higher elevation, the bulk water meter may be provided with a suitable air valve before the meter in order to reduce inaccuracy and to protect it from being damaged.

1.1.3 Installation of Prepaid Water Meter

The following guidelines should be used while installing the prepaid water meters:

(a) Before installing the prepaid meter first check its accuracy on a meter test bench at minimum and permanent flow rates. It will be costly to install a water meter that might underperform from the day of installation,

(b) The installation has to strictly follow the manufacturer’s instructions,

(c) Unless the instructions allow for downpipes or an installation at an angle, most water meters require a horizontal installation. A water meter mounting position different to the instructions given by the manufacturer increases the friction of moving parts,

(d) Install the meter at pipe level. The location of the meter should be such that it is not possible for air pockets to develop in the meter, for instance the meter should not be located at high points in the pipeline or operated under half full pipe conditions. The installation on top of a standpipe could lead to the meters reading air flow,

(e) Fix the meter between two straight un-obstructed pipes: the upstream pipe’s length should equal to 10 times the pipe diameter and the downstream pipe’s length should be equal 5 times the pipe diameter,

(f) The pipe diameter should not be reduced directly in front and behind the prepaid water meter,

(g) All regulations of the flow (e.g. operation of gate valve) should be realized after the meter.

1.1.4 Operation and Maintenance of Ordinary Water Meters

Regular maintenance of water meters include cleaning of dirt box or strainer time to time, replacement of gaskets upon its wear and tear, cleaning of chamber where meter is installed and preventing water seepage in it, verifying whether it is indicating correct reading cleaning of spare parts when disassembled for any repairs or verification with detergents solution in warm water. Normally, general maintenance and repairs recommendations are given by the manufacturer.

1.1.4.1 Functional Principles of Water Meters

Water meters are divided into two classes:

- Volumetric water meters, when the volume is mechanically measured through a known volume of a measuring chamber, and

- Inferential water meters, when the meter determines the velocity from variables such as pressure differences across a devices like and orifice plate, transit time of sound waves, changes in magnetic field.

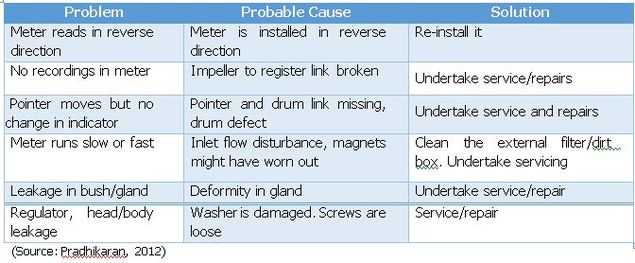

In general, domestic meters should be taken out of service every 5 to 7 years and completely overhauled. The systematic inspection and replacement of consumption meters is an important aspect of routine maintenance. Records should be kept on the condition of meters to guide future procurement and enable the Utility to take measures against water loss. Representative pothole checking of service connections within 5 years of service (avoid leaks due to deterioration) should also be done. Normally, general maintenance and repairs recommendations are given by the manufacturer. Table 16.1 illustrates the troubleshooting of water meters.

Table 16. 1: Typical Troubleshooting of Water Meters

1.1.4.2 Inspection of Water Meters

(a) Clean all water meter parts thoroughly;

(b) Make sure the gear train runs freely;

(c) Check the action of the disc in the chamber;

(d) Remember that friction is just as detrimental to correct registration (reading) as slippage;

(e) Store meters away from heat;

(f) Use a calibrated meter as a standard of comparison for tolerances and clearances;

(g) After every repair, retest the meter for accuracy;

(h) If necessary, call the manufacturer for advice

1.1.4.3 Types of Water Meter Testing

(a) Meter Shop Test – pull out meter and send it to testing laboratories/shops for testing /recalibration (equipment and service available usually at large utilities).

(b) Volumetric Method (no dismantling) – using a container with known volume, a variance of +/- 4% should be pulled out for recalibration)

(c) Using a Calibrated Test Meter – the meter should be put in series with a calibrated meter. In principle, readings should be the same. Record the difference; +/- 4% off should be re-calibrated.

1.1.4.4 Water Meter Testing (If a Test Bench is Available)

(a) Install/fix water meter on Test bench;

(b) Open supply valve, close end valve and inspect for leaks;

(c) Record the initial reading;

(d) Open end valve, run the test and close end valve at desired volume.

(e) Record the final reading;

(f) Compute meter accuracy;

(g) Identify Over/Under registering meters;

(h) Calibrate by adjusting regulator or rheostat (+/-);

(i) Re-test the water meter;

(j) Seal the water meter cover and regulator plug.

1.1.5 Metering Accuracy

For accurate water flow measurements, various characteristics of the meter have to be known, before a suitable meter type with the right specifications can be chosen to fulfil this task. The characteristics are as follows:

- Metering accuracy according to Water quality: Metering accuracy is significantly affected by suspended solids and depositions. Dirty water will cause under-registration e.g. with Positive Displacement Meters as well as with Velocity Meters. The Positive displacement meters may stop when a particle bigger than the spare space between the piston/disc and the chamber passes through the strainers of the meter. For Velocity meters, the depositions may cause over registration at medium-high flows and under registration at low flows. However, on the long term, deposits from suspended particle can grow so large that they can prevent the impeller from rotating, temporarily or permanently, causing a severe under registration of the meter

• Metering accuracy according to Flow range/Rangeability (consumption pattern): Water meter measure accurately only flow rates that lie within its rangeability (Meter accuracy according to (TZS 782-5: 2015- ISO 4064-5: 2014). Flow rates beneath the specified minimal flow will be registered inaccurately or not at all. Operating a meter at either minimal or maximum flow rate, will reduce the life span of the meter and change its accuracy curve. While in the later case impact is seen sooner • Metering accuracy according to Oversized Meter– results in High non-revenue water. If the water meter is too large, the flow rates might be lower than the minimum flow rate and cause under-registration will be significant even from the first day of installation. Also oversized meters are more costly than rightly sized meter. • Metering accuracy according to Undersized Meter –results in accuracy and high pressure loss. If the meter is too small, the degradation of the accuracy will be accelerated. While the meter might be accurate at the beginning, in the short period of time, the pieces in contact with them, will break down leading to significant metering errors. Undersized water meters can cause excessive pressure loss. • Metering accuracy according to Metrological Class The Metrological class defines the accuracy of a water meter. There are old and new standard norms of the Metrological classes. Until 2003-2004, the metrological classes of meters were defined by the Standard (TZS 782-5: 2015- ISO 4064-5: 2014). This Standard, defines a meter by its Nominal Flow (Qn), called Qn, and Accuracy Class. There are 4 accuracy classes A, B, C, D. Each class sets a range of flow rates on which the meter must maintain its accuracy. A is the narrowest, D is the widest. Each meter operates accurately for its designed flow ranges, e.g. a Class A meter can be absolutely suitable if the consumptions are done according to a very narrow range of flow rates, which is often the case for irrigation.

Requirement for accuracy: The Norm is demanding compliance of meters with the following accuracy limits for different flow rates: (a) +- 5% accuracy between Minimum and Transitional Flow (b) 2 % between Transitional and Maximum Flow

Table 16.2: Definition of Flow Rates Flow rates Description

Minimum Flow (Qmin) Minimum flow that can be registered by the meter within 5% accuracy Transitional Flow (Qt) Flow at which the meter inaccuracy is not more than 2% Nominal Flow (Qn) depends on meter size (refer to table underneath) Maximum Flow (Qmax) 2 x Qn Note: Qn is the nominal flow rate as half the maximum flow rate

Pressure drops: The meters must not have a pressure drop higher than 1 bar at the maximum flow and 0.25 bar at the nominal flow.

Please note: If the regular water flow rate is around or above the Maximum flow rate for which the meter has been designed, the measuring unit of the meter will be damaged progressively till it stops to work.

16.1.5 Operation and Maintenance of Flow Meters

Flow meters were described in Volume I. Regular monitoring of flow meters include periodic checking of range and zero setting, bearing wear out checking, deposits in flow meter, corrosion of attached pipes etc. Some of the general troubleshooting is listed in the Table.16.2.

Table 16. 2: General Troubleshooting of Flow Meters Probable Cause Solution Problem: Erratic Reading Operating below lower ranges Replacement of meter, change range setting Lower static pressure Remove air trap Clogged impulse piping Clear choke up Air trap in impulse piping Remove air trap Frequent air trap in impulse piping Change piping slope/change meter Problem: Inaccurate Reading Pipeline internally encrusted Clean internal surface of pipeline/replace Scaling at tapping points Clean the tapping points Orifice edge blunt Replace orifice plate Mismatch of flow meter and pipeline Remove the mismatch Gathering of concrete piece, bricks, debris etc at orifice Remove the external particles

Leakage in flanged coupling Rectify the leakage

(Source: Pradhikaran, 2012)

16.1.6 Operation and Maintenance of Ordinary Bulk Water Meters

Ordinary bulk flow meters are used at intakes, treatment works and in the distribution systems at reservoirs and bulk supply. They are installed for purposes of monitoring large flows of water for water system management and commercial billing purposes. They are normally equipped with helical vanes with pulse outputs for operation with various auxiliary equipment. Different body length sand material types are available to meet all requirements.

Combination meters are manufactured for installations where wide variation in flow can be expected, such as in multi-story buildings, hospitals, schools, offices and other places where both low and high flows can occur due to several consumptions users. These wide flow ranges are measured by using a built-in changeover valve together with small residential meters and large bulk meter.

Large commercial single jet meters are also available which have a low flow capability, which makes them ideal for revenue collection. Electromagnetic water meters are also available which are designed for measuring bulk flows in a wide range of applications including irrigation management of agricultural land. All bulk meters should be tested to ensure that they meet approved standards.

16.1.7 Operation and Maintenance of Prepaid Water Meters

Prepaid water systems are an effective and efficient way of collecting water tariffs and offer a high level of convenience to both the users and local water supply authorities. They save time and do not require unnecessary paperwork. Moreover, the systems minimize cash transactions and, therefore, contribute to the transparency of the tariff collection. In rural areas in Tanzania, the management of these prepaid systems has been strengthened with the formation of Community-Based Water Supply Organisations (CBWSOs). Prepaid meters have been operating successfully in the Districts of Kishapu, Karatu and Babati.

Most prepaid water meters use a mechanical water meter, coupled to an electronics module with a credit meter and a water control valve. When water flows, pulses are generated by a probe connected to the mechanical meter. The pulses are converted into credits that are subtracted from the total credits loaded by the customer. The valve closes when credit is exhausted or if there is tampering with the components. Prepaid systems use rotating piston and multijet water meters. The accuracy of these meters can be easily affected by grit, sand, and air; and frequent supply interruptions raise the risk of malfunction. This is a significant vulnerability for prepaid metering systems especially in urban areas, where there are ageing networks, discontinuous supply, and low pressure fluctuations. Electromagnetic and ultrasonic prepaid meters are technically better suited to networks with supply interruptions. These models are also highly accurate, resilient to pressure changes, air, and grit have no moving parts.

(a) Prepaid Public Standpipes

A customer using a standpipe, kiosk or water point loads credit bought from designated vendors using a programmed metal key, a smartcard, or a keypad. Dallas keys, or Buttons, are currently the most widely used, and consist of a computer chip mounted in a stainless steel container that looks like a large watch battery. Programmed keys and smartcards allow for a two-way exchange of data. A credit vendor loads credit onto the customer’s Dallas key using a point-of-sale device, and uploads consumption data from the customer’s prepaid meter for analysis later. This data can be used to track consumption trends and flag exceptions (unusually high or low consumption) or for follow-up. Numerical tokens and keypads are one-way only, and require separate data collection to track consumption.

(b) Individual Domestic Connections

The customers use their own prepaid meters, and load credit using a tag, smartcard, or keypad. The tag, card, or code can only be used on the specific meter for which it is programmed. Once the credit is loaded into the meter’s memory, customers do not have to use the key each time they draw water. A growing number of utilities acknowledge that regular monthly meter reading is essential to collect consumption data to calculate their water balance, reconcile sales, and monitor Non Revenue Water (NRW). Some utilities now insist that each prepaid device includes a conventional/post-paid mechanical meter, if necessary, in addition to an electronic meter. If the prepaid unit fails for any reason, the mechanical meter can still be read and supports conventional billing and payment.

(c) Prepaid Bulk Meters for Commercial and Institutional Customers

The Prepaid Bulk flow meters are used where wide variation in flows can be expected, such as in multi-story business buildings, hospitals, schools, offices and other places where both low and high flows can occur due to several consumptions users. These wide flow ranges are measured by using a built-in changeover valve together with small residential meters and large bulk meter. All bulk flow prepaid meters should be tested to ensure that they meet approved standards. A representative of the customer loads credit using a tag, smartcard, or keypad. The meter needs to be designed for far higher volumes than domestic meters and far greater accuracy, given the volumes. The large volumes of water sold to commercial and institutional customers comprise a significant source of income for water supply service providers in most urban towns.

Figure 16. 1 (a) & (b): E-Water Point in Sangara Village, Babati. A token used by E-Water Users to Get Water

16.1.8 Testing and Calibration of Water Meters

The testing & calibration of a water meter is essential before putting it into use as it is a statutory requirement and may be done periodically in order to ascertain its performance. It is likely that its accuracy of measurement may deteriorate beyond acceptable limits in the course of its use.

A meter suspected to be malfunctioning is also tested for its accuracy of measurement. The testing is done as per TZS 782-2: ISO 4064-2:2014. A faulty meter if found to be repairable, is repaired and tested and calibrated for its accuracy before installation .The metering accuracy testing is carried out at Qmin, Qt & Qmax, separately where: (a) Qmin: Lowest flow rate at which the meter is required to give indication within the maximum permissible error tolerance. It is determined in terms of numerical value of meter designation in case of ISO 4064. (b) Qt: The flow rate at which the maximum permissible error of the water meter changes in value. (c) Qn: Half the maximum flow rate Qmax. (d) Qmax: The higher flow rate at which the meter is required to operate in a satisfactory manner for short periods of time without deterioration. (e) The accuracy of water meters is divided into two zones i.e.

(i) Lower measurable limit in which ±5% accuracy from minimum flow to transitional flow (exclusive), and (ii) Upper measurable limit in which ±2% accuracy from transitional flow (inclusive) to maximum flow.

The procedure for conducting the above test is as follows: Water meter is fixed on a test bench horizontally or vertically or in any other position for which it is designed and with the direction of flow as indicated by arrow on its body. By adjusting the position of regulating valve on the upstream side, the rate of flow is adjusted. At the desired rate of flow, the difference in pressure gauge readings fitted on upstream and downstream side of the water meter is noted. The flow is now stopped with regulating valve and measuring chamber is emptied and zero water levels on manometer attached to measuring chamber is correctly adjusted. Initial reading of the water meter from its recording dial is noted. Now the flow at the set rate is passed through the water meter and the discharge is collected in the measuring chamber. After passing the desired quantity of water through the meter, the flow is once again stopped. The discharge as recorded by measuring chamber is noted. The final reading of the water meter is noted. The difference between the initial and final readings of the water meter gives the discharge figure recorded by water meter. Now the discharge recorded by measuring tank is treated as ideal. The discharge recorded by water meter is compared with this ideal discharge. If the quantity recorded by water meter is more than the ideal, the meter is called running fast or vice versa.

The difference in the quantity recorded by the meter from the ideal quantity is considered as the error. This error is expressed in percentage. If the limits of error for the meter exceed that specified in the TZS/ISO standards concerned the meter is readjusted by the regulator if it is available in the meter. A change in position of the regulating screw will displace the error curve (calibration curve) in parallel to former the position. With the closing of the regulating orifice the curve will shift upward while opening the same will lower the curve. If the curve does not get into acceptable limit the meter is not used. Some of the organizations are accepting accuracy limit for repaired water meter double the value of new water meters at respective zones i.e. for upper zone accuracy is ±4% & for lower zone accuracy is ±10%. In Tanzania, the Agency for Weights and Measures as per relevant Law.

16.1.9 Repairs, Maintenance and Troubleshooting of Water Meters

The water meters are mechanical devices, which normally deteriorate in performance over time. Water meters in good working conditions are the basis to determine the water network efficiency and for accurate billing. The fact that a meter does not show outward signs of any damage and has a register that appears to be turning, does not mean that the meter is performing in a satisfactory manner. It is necessary to ascertain the following preventive cares for water meters after proper installation:

(a) Preventive maintenance: (i) Proper handling, storage and transportation of water meters, (ii) To clean the dirt box or strainer wherever installed, (iii) To replace the gaskets, if any; (iv) To clean the chamber in which the meter is installed and keep free from flooding, & seepage, (v) To remove the meter for further internal repair/replacement if it does not show correct reading pattern.

(b) Breakdown maintenance: Replacement of broken glass, lid and fallen wiper wherever provided: These are the only basic breakdowns observed during periodical inspection. If a meter found not working, then it shall be removed immediately and sent to the meter service workshop. In meter workshops normally following steps are performed to carry out the repairs: (i) Disassembling of water meters including strainer, measuring unit, regulator, registering device, (ii) Clean all disassembled spare parts in detergent solution in warm water, (iii) Inspect the cleaned parts and replace worn parts and gaskets, if any, (iv) Inspect the meter body spur threads and cover threads, (v) Inspect the sealing surface on meter body and paint the meter body, if necessary, (vi) Inspect the vane wheel shaft pinion, bearing & pivot, (vii) Inspect the vane wheel chamber, (viii) Reassemble the water meter properly after reconditioning, (ix) Calibrate & test the repaired water meter for leakage & accuracy as per ISO:4064-2:2014,TZS 782-2:2018, (x) Make entry in the life register of that water meter for keeping history record.

16.1.10 Prevention of Tampering of Water Meters

In order to prevent tampering, following precautions should be taken: (a) The water meters, shall be installed properly in the chamber with lock and key or in the cast iron covers with lock and key in order to avoid tampering, (b) The water meters must be sealed properly, (c) The water meters shall not allow reversible flow; it should register flow in forward directions only, (d) The water meter dials should be easily readable without confusions, (e) The lid, glass of water meters must be made up of tough materials as per ISO: 4064-4:2014, TZS 782-4:2018 and shall be replaced timely, (f) The wiper or dial as far as possible is avoided, (g) In case of magnetically coupled meters, the proper material to shield magnets must be provided in order to avoid the tampering of such meter by outside magnets in the vicinity of the meter, (h) Periodic inspection/checking at site is essential to ensure the proper working of the meter, (i) Special sealing arrangements may be necessary and provided for bulk meters where by unauthorized removal of the meter from the connection can be detected.

In addition to the above, to tackle the problems of tampering, suitable penalty provisions/clauses shall be there in the rules or the water supply agreement with the consumer. This will also discourage the consumer tendencies of neglecting water meter safety.

16.1.11 Automatic Water Metering Systems

Water meter is a cash register of a water supply agency/authority/utility. Consumption based water rates require periodic reading of meters except in remote or automated meter reading of meters. Except in remote or automated meter reading these readings are usually done by meter readers visiting consumers premises one by one and noting down the indicator reading by the meter. These readings are recorded manually in books or on cards and later keyed in manually to a customer accounting or billing system. In some cases, meter readers use Hand held Data Entry Terminals to record meter readings. Data from these devices are transferred electronically to a billing system. In other cases, key entry has been replaced by mark-sense card readers or optical scanners.

In case the environment of meter reading is not favourable to the meter reader as the water meters are at times installed in underground chambers; these chambers are filled in many cases with water, reptiles or insects. In some consumers connect their electrical earth terminal to water supply utility/authority/agency pipe which endangers the safety of the meter reader or premises are not accessible to the meter reader. The solution to the above difficulties is to install automatic system to read meters and process the results by computer.

The data can be captured by the meter readers from the meter in one of the following ways: (a) Manual entry into meter books, (b) Manual entry into portable hand held entry terminals or recorders, (c) Direct electronic entry from meter registers either into portable data terminals or display units from which readings are transcribed in the field, (d) Telemetry link through radio, telephone.

16.2 Instrumentation

Some instrumentation is expected to be applied in the following areas:

16.2.1 Level Measurement

Instrumentation facilitates coordination of various water parameters, which are essential for optimization of water supply & treatment plant. One of the important parameters amongst them is water level measurement, which is carried out at various locations viz. water reservoir, inlet chamber, open channel, alum feeding tank, lime tank, filter beds, air vessel, sump well, etc. This measurement is accomplished in water works by two following ways: (a) Direct Method, (b) Inferential Method.

16.2.2 Pressure Measurement

In water supply networks, pressure parameter plays a very important role in order to get sufficient water to the consumers. Similarly in flow measurement by differential pressure type flow meter, differential pressure measurement across the primary element is the main physical parameter to inter-link with the flowing fluid. This pressure or differential pressure measurement is accomplished with the help of the following methods in water works: (a) Manometers, (b) Elastic Pressure Transducers, (c) Electrical Pressure Transducer.

16.2.3 Capacitors

Capacitors are needed to be provided invariably in all the pumping stations for maintaining required power factor thereby saving of energy. Pre-requisites for satisfactory functioning of capacitors ensure the following points: (a) A capacitor should be firmly fixed to a base, (b) Cable lugs of appropriate size should be used, (c) Two spanners should be used to tighten or loosen capacitor terminals. The lower nut should be held by one spanner and the upper nut should be held by the spanner to avoid damage to or breakage of terminal bushings and leakage of oil, (d) To avoid damage to the bushing, a cable gland should always be used and it should be firmly fixed to the cable-entry hole, (e) There should be a clearance of at least 75 mm on all sides for every capacitor unit to enable cooler running and maximum thermal stability. Ensure good ventilation and avoid proximity to any heat source, (f) While making a bank, the bus bar connecting the capacitors should never be mounted directly on the capacitor terminals. It should be indirectly connected through flexible leads so that the capacitor bushings do not get unduly stressed, (g) Ensure that the cables, fuses and switchgear are of adequate ratings.

16.2.3.1 Operation and Maintenance of Capacitors

(a) The supply voltage at the capacitor bus should always be near about the rated voltage. The fluctuations should not exceed ±10% of the rated voltage of the capacitor, (b) Frequent switching of the capacitor should be avoided. There should always be an interval of about 60 seconds between any two switching operations, (c) The discharge resistance efficiency should be assessed periodically by sensing, if shorting is required to discharge the capacitor even after one minute of switching off. If the discharge resistance fails to bring down the voltage to 50 V in one minute, it needs to be replaced, (d) Leakage or breakage should be rectified immediately. Care should be taken that no appreciable quantity of imp- regnant has leaked out, (e) Before physically handling the capacitor, the capacitor terminals shall be shorted one minute after disconnection from the supply to ensure total discharging of the capacitor, (f) Replace capacitor if bulging is observed.

16.2.4 Water Hammer Control Devices

Maintenance requirements of water hammer devices depend on type of water hammer control device, nature of its functioning, water quality, etc. Type of water hammer control devices used in water pumping installations is as follows: • Surge tank and/One-way surge tank, • Air vessels (air chamber), • Zero velocity valve and air cushion valve, • Surge anticipation valve (surge suppressor), • Pressure relief valve.

General guidelines for maintenance of different types of water hammer control devices as follows:

(a) Surge Tank and One-Way Surge Tank Quarterly: (i) Water level gauge or sight tube provided shall be inspected, any jam rectified, (ii) All cocks and sight tube flushed and cleaned.

Yearly: The tank shall be drained and cleaned once in a year or earlier if frequency of ingress of foreign matter is high.

(b) Valve maintenance: (i) Maintenance of butterfly valve, sluice valve and reflux valve shall be attended, (ii) Painting: Painting of surge tanks shall be carried out once in 2 years.

Air-Vessel Daily: (i) Check air-water interface level in sight glass tube, (ii) The air water level should be within range marked by upper and lower levels and shall be preferably at middle, (iii) Check pressure in air receiver at interval of every 2 hours.

Quarterly: (i) Sight glass tube and cock shall be flushed, (ii) All wiring connections shall be checked and properly reconnected, (iii) Contacts of level control system and pressure switches in air supply system shall be cleaned.

Yearly: (i) The air vessel and air receiver shall be drained, cleaned and dried, (ii) Internal surface shall be examined for any corrosion etc. and any such spot cleaned by rough polish paper and spot-painted, (iii) Probe heads of level control system shall be thoroughly checked and cleaned accessories: Maintenance of panel, valves and air compressor etc. shall be carried out as specified for respective appurtenances.

Zero-Velocity Valves and Air Cushion Valve Foreign matters entangled in valve shall be removed by opening all hand holes and internal components of the valves including ports, disk, stem, springs, passages, seat faces etc. should be thoroughly cleaned and checked once in 6 months for raw water and once in a year for clear water application.

16.3 Telemetry and SCADA Systems

16.3.1 Manual Monitoring

Normally the managers of O&M of water supply scheme monitor levels in service reservoirs, pressures and flows in a distribution system, and on operation of pumps such as hours of pumping and failure of pumps and monitor water quality by measuring residual chlorine. The line department/unit usually uses the telephone line or wireless system to gather the data, uses his discretion gained with experience and takes decisions to ensure that the system is operating with required efficiency. Manual collection of data and analysis may not be helpful in large undertakings if water supply utilities have to aim at enhanced customer service by improving water quality and service level with reduced costs. This is possible if the management acquires operational data at a very high cost.

16.3.2 Telemetry

The inspection, monitoring and control of O&M of a water supply utility/authority/agency can be automated partially through telemetry. Telemetry enables regular monitoring of the above data on real time basis and the data is provided to anyone in the organization who can review the data and take decision. In Telemetry system, probes/sensors are used and sense, generate signals for the level, pressure and flow in a given unit and transmits the signals by radio/by Telephone. Normally radio link is used and telephone line with a modem is used as spare communication. Microwave satellite or fiber-optic transmission systems are also used for data transmission. The water pumping stations may communicate via a cable buried with the pipe. However there may be locations where the main power may not be available and hence solar panels with a battery charger are used to power the remote terminal unit (RTU) and the radio. In urban areas RTU s can communicate on cell phones and or packed radio networks. For remote locations satellite technology is also available.

(a) Data for Collection by Telemetry The data includes levels in service reservoirs, pressures and flows in a distribution system, flows/quantity of delivered into a SR and data on operation of pumps such as voltage, amperes, energy consumed, operating times and down times of pumps and chlorine residuals. In a telemetry system up-to the minute real time information is gathered from remote terminal unit located at the water treatment plant, reservoir, flow meter, pumping station etc. and transmitted to a central control station where the information is updated, displayed and stored manually or automatically.

(b) Processing Data from Telemetry The meter readings from reservoirs are useful information for managing the distribution system and helps in preventing overflow from reservoirs. However, the effectiveness of telemetry in pumping operations is dependent on reliability of instrumentation for measuring flows, pressures, KWh meters. Standard practice is to calculate pump efficiency and water audit calculations on a monthly basis. Telemetry can also be used to supervise water hammer protection system wherein the pump failures are linked to initiate measures to prevent occurrence of water hammer.

(c) SCADA Systems (Supervisory Control and Data Acquisition) Supervisory Control and Data Acquisition (SCADA) systems provide control functionality and alarms at water supply scheme sites which in many cases are very remote. These systems were often used to solve single problems such as reducing power cost, or improving control of a particularly complex operation. The installation of SCADA has subsequently been seen as a means to satisfy a variety of increasing pressures such as consumer demands, regulatory requirements, and to also satisfy the need to reduce operational costs. The deployment of SCADA systems has been extended to cover large water supply schemes and has been found very effective.

An important challenge to the commercial success of the organization is to harness the data collection power of the SCADA systems to provide a wealth of operational information to all levels of the organization. Past systems that have been installed in some of the water treatment plants have failed to meet expectations regarding data availability. This has primarily been attributed to difficulties associated with merging traditional engineering and new IT methodology, and a lack of system openness in data interconnectivity and communications.

(d) Remote Terminal Units (RTU) A Remote Terminal Unit (RTU) is a microprocessor-controlled electronic device that interfaces objects in the physical world to a SCADA by transmitting telemetry data to the system and/or altering the state of connected objects based on control messages received from the system. Modern RTUs are usually capable of executing simple programmes autonomously without involving the host computers of SCADA system to simplify deployment, and to provide redundancy for safety reasons. An RTU in a modern water management system will typically have code to modify its behaviour when physical override switches on the RTU are toggled during maintenance by maintenance personnel. This is done for safety reasons; a miscommunication between the system operators and the maintenance personnel could cause system operators to mistakenly enable power to a water pump when it is being replaced, for example.