Difference between revisions of "Chapter Nine: Design of Water Structures"

| (5 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=Chapter Nine: Design of Water Structures = | =Chapter Nine: Design of Water Structures = | ||

| + | <div style="text-align: justify"> | ||

The main components of a water project include water intakes, break pressure tanks, water points, valve chambers and storage/sedimentation tanks. The following sections describe the design procedures for various water structures. | The main components of a water project include water intakes, break pressure tanks, water points, valve chambers and storage/sedimentation tanks. The following sections describe the design procedures for various water structures. | ||

| − | == | + | == Sizing And Locating Water Structures == |

=== Tanks === | === Tanks === | ||

==== Storage tanks ==== | ==== Storage tanks ==== | ||

| Line 507: | Line 508: | ||

[[Image:Figure9.9.JPG|650px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | [[Image:Figure9.9.JPG|650px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| − | + | ==== Groundwater Prospecting ==== | |

'''(a) Required data'''<br> | '''(a) Required data'''<br> | ||

Prior to carrying out hydrogeological and geophysical investigation a thorough | Prior to carrying out hydrogeological and geophysical investigation a thorough | ||

| Line 569: | Line 570: | ||

the groundwater controls. Recharge in this formation is by rain water infiltration | the groundwater controls. Recharge in this formation is by rain water infiltration | ||

through the superficial formation, shear or weathered rocks and fractures. | through the superficial formation, shear or weathered rocks and fractures. | ||

| + | Shear/ weathered or fractured zones are the expected aquifer points in the | ||

| + | surveyed area. | ||

| + | |||

| + | '''(c) Geophysical methods'''<br> | ||

| + | Geophysical surveys are a relatively cheaper and faster way in groundwater | ||

| + | investigation compared to drilling of exploratory wells. This is the reason why | ||

| + | geophysical surveys are applied in the preliminary stages of investigations. | ||

| + | However, geophysical surveys require specialized professionals (Geophysists | ||

| + | or Hydrogeologists) to execute the surveys and to interpret the results. Several | ||

| + | methods are used in hydrogeology depending on the geological formation as | ||

| + | described below: | ||

| + | |||

| + | '''(i) Geo-electrical resistivity soundings'''<br> | ||

| + | With the resistivity method normally an electrical current, generated by an artificial | ||

| + | source, is sent through the ground by means of two current electrodes at the land | ||

| + | surface. The resulting electrical potentials are measured with two other electrodes, | ||

| + | also at the land surface. Since rock types have different electrical properties | ||

| + | depending on their density, pore fluids, porosity etc., the strength of the current | ||

| + | applied gives a measure of the apparent resistivity of the rock. By varying the | ||

| + | distances between either the current electrodes (Schlumberger arrangement,), or | ||

| + | both types of electrodes (Wenner arrangement) apparent resistivity at different | ||

| + | depths and layer thicknesses are obtained. The wider the spacing distance, the | ||

| + | deeper the layers involved in transmitting the electrical current. | ||

| + | The major advantage with the resistivity method as far as ground water | ||

| + | investigations are concerned is that it gives direct indications of the presence of | ||

| + | water as resistivity is a function of water content of the rocks. Other geophysical | ||

| + | methods tend to provide indirect indications. | ||

| + | |||

| + | '''(ii) Electromagnetic (EM) methods'''<br> | ||

| + | This method is cheap and fast, as it does not involve extended walking with | ||

| + | electrodes as for the case of resistivity. The methods rely on the measurement of | ||

| + | secondary magnetic fields generated by conducting bodies in the ground when | ||

| + | subjected to primary signal. The principle is that a time varying low frequency | ||

| + | electromagnetic field is generated by a transmitter at the land surface, which | ||

| + | later is transformed by an electrical conductor underground. The method is | ||

| + | useful in detecting buried conducting bodies such as fractured fault zones, dikes | ||

| + | etc. This method may also be used in detecting polluted groundwater or, fresh | ||

| + | water/brackish water interface. | ||

| + | |||

| + | '''(iii) Magnetic method'''<br> | ||

| + | Magnetc profiling is used to measure the variation of the total magnetic field in | ||

| + | relation to geology along the profiles. The magnetic field of fractures/features, | ||

| + | dykes system and deeply weathered zone differs considerably from surrounding | ||

| + | rocks. The changes are increase or decrease in the normal field of the area. | ||

| + | |||

| + | '''(iv) Seismic methods'''<br> | ||

| + | The method has limited direct use in groundwater exploration. However, it is | ||

| + | useful in determining the depth to the bed rock. The methods makes use of the | ||

| + | elastic property of rocks. The seismic waves are generated on the ground by | ||

| + | explosion or any other instantaneous release of energy into the earth. | ||

| + | |||

| + | ===== Drilling ===== | ||

| + | After the survey, the drilling work in areas that look promising follows. It is the | ||

| + | duty of the hydrogeologist to supervise all drilling activities and provide technical | ||

| + | advice in the course of drilling. Another responsibility is the analysis of rock | ||

| + | cuttings, identification of the productive zones and recommending the borehole | ||

| + | depth. During drilling, drillers must keep a detailed log of the drill cuttings | ||

| + | obtained from the advancing borehole. In addition, after the drilling has been | ||

| + | completed but before the well is installed, it is often desirable to obtain more | ||

| + | detailed data on the subsurface geology by taking geophysical measurements in | ||

| + | the borehole. | ||

| + | |||

| + | '''(a) Drilling Methods'''<br> | ||

| + | There are several different types of rigs available for drilling water boreholes. | ||

| + | They vary in size, capacity and capability depending on the type of formation | ||

| + | expected and the depth required. There are rigs which do not perform well in | ||

| + | hard rock formations and there are those that are multipurpose. Percussion and | ||

| + | rotary-percussion drilling methods are generally the most applicable techniques | ||

| + | for drilling in igneous and metamorphic rocks. If a significant thickness of granular | ||

| + | or other overburden materials is present, a combination of methods can be | ||

| + | effective, although not very practical. Cable-tool, hydraulic-rotary percussion and | ||

| + | air-rotary percussion (down-the-hole air hammer) and foam drilling modifications | ||

| + | are the most common types of equipment in use today for such rock types | ||

| + | (Referred to web: resvol.design). | ||

| + | |||

| + | '''(b) Borehole Logging'''<br> | ||

| + | '''(i) Rock sampling'''<br> | ||

| + | Rock cuttings are collected, normally at a 2 meters interval while drilling is in | ||

| + | progress and a proper borehole log is kept. The samples are analysed to identify | ||

| + | the water bearing zones, and the driller keeps a record of penetration rate to | ||

| + | assist in identifying the hard formations and their thickness as well as recording | ||

| + | the water struck levels. | ||

| + | |||

| + | '''(ii) Down-hole logging'''<br> | ||

| + | For accurate description of the penetrated strata, application of geophysical | ||

| + | logging methods assist in the determination of thickness of formations, the zones | ||

| + | of highest porosity and water quality. | ||

| + | |||

| + | ===== Siting of Well/Borehole ===== | ||

| + | The borehole siting methodology should be adjusted to the hydrogeological | ||

| + | conditions and the local experience and should be done by an experienced | ||

| + | hydrogeologist. It should include the following steps: | ||

| + | * Identification of fracture zone on aerial photographs, satellite images and maps; | ||

| + | * Identification of fracture zones in the field using resistivity profiling, Electrical profiling, and | ||

| + | * Vertical Electrical Sounding (VES). | ||

| + | |||

| + | ===== Well Design ===== | ||

| + | Well design is done in two stages, the preliminary design and the final well design. | ||

| + | Designing consists primarily of deciding the well depth, casing diameter, screen | ||

| + | type and slot size and its position in the well. Once the well site is determined, | ||

| + | a preliminary well design is prepared by an experienced hydrogeologist or | ||

| + | driller based on hydro-geologic information gathered before the drilling. This | ||

| + | preliminary design is the basis of the well drilling contract and the cost estimates. | ||

| + | During the drilling period, the preliminary well design will be adjusted based on | ||

| + | actual observations and findings on the specific site. This adjusted design will | ||

| + | then become the final well design. During this stage, the design assumptions | ||

| + | used are verified and become actual design parameters, such as water table | ||

| + | level, drawdown, depth and thickness of the geologic layers, types of material of | ||

| + | each geologic layer encountered, and other relevant information. | ||

| + | The main objective of the design is to construct a well that: | ||

| + | (a) Is structurally stable;<br> | ||

| + | (b) Is able to extract groundwater at the desired volume and quality;<br> | ||

| + | (c) Has the proper and correctly placed screens or slots to tap the productive | ||

| + | aquifers as well as to allow effortless flow of ground water into the well;<br> | ||

| + | (d) Has enough space to house pumps;<br> | ||

| + | (e) Has appropriate gravel packing that minimizes entry of sediments and sand | ||

| + | particles.<br> | ||

| + | |||

| + | ==== Structures for Rainwater Harvesting ==== | ||

| + | ===== Roof Catchment ===== | ||

| + | Following details are available:<br> | ||

| + | Catchment: Rooftop<br> | ||

| + | Area of the catchment (A) = 100 sq. m.<br> | ||

| + | Average annual rainfall (R) = 611 mm (0.61 m)<br> | ||

| + | Runoff coefficient (K) = 0.85<br> | ||

| + | |||

| + | Family size = 5<br> | ||

| + | Per capita household water requirement = 25 litre/person/day<br> | ||

| + | a) Calculate the maximum amount of rainfall that can be harvested from the | ||

| + | rooftop:<br> | ||

| + | Annual water harvesting potential, S = 0.85 x 100 x 0.61 = 51 cu. m (51,000 litres)<br> | ||

| + | b) Determine the tank capacity: This is based on the dry period, i.e., the period | ||

| + | between the two consecutive rainy seasons. For example, with a rain period | ||

| + | extending over four months, the dry season is of 245 days.<br> | ||

| + | c) Calculate drinking water requirement for the family for the dry season, | ||

| + | C = 5 x 25 x 245 = 30,625 litres <br> | ||

| + | As a safety factor, the tank should be built 20 per cent larger than required, | ||

| + | i.e., 36,750 litres. This tank can meet the basic drinking water requirement of a | ||

| + | 5-member family for the dry period. A typical size of a rectangular tank constructed | ||

| + | in the basement will be about 5.0 m x 5.0 m x 1.5 m.<br> | ||

| + | Note that in this case the analysis of the water availability/harvested against | ||

| + | satisfaction of the demand need to be done. Alternatively, other detailed analysis | ||

| + | such as the cumulative mass curve should be carried out for storage determination.<br> | ||

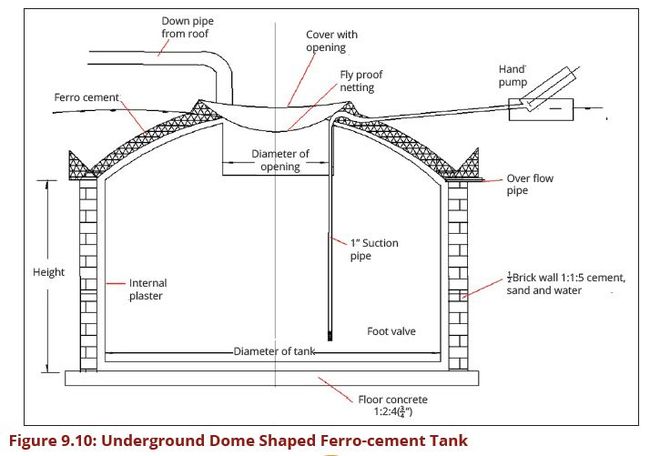

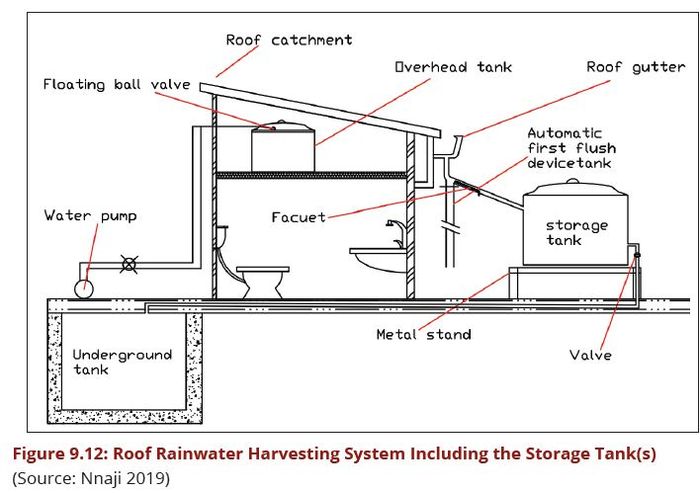

| + | Figure 9.21 shows a typical rooftop water harvesting configuration. | ||

| + | |||

| + | [[Image:Figure9.10.JPG|650px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| + | |||

| + | Storage tanks should be located as close to supply and demand points as | ||

| + | possible and should be protected from direct sunlight. Storage tanks can be | ||

| + | elevated, on the ground or underground. They can be made of plastic materials, | ||

| + | concrete or galvanised steel. Configuration depends on the size of the tank. | ||

| + | For large catchment, underground tanks fitted with a pump to draw water to | ||

| + | elevated distribution tank are preferable. Underground tanks can be rectangular | ||

| + | or cylindrical, reinforced or plain concrete. Overflow pipes must be installed in | ||

| + | the top of the tank to allow the safe disposal of excess rainwater. The size of | ||

| + | the overflow pipe should be the same as that of the inlet pipe, with mesh at the | ||

| + | bottom to prevent rats, squirrels, cockroaches, and other pests from entering. | ||

| + | |||

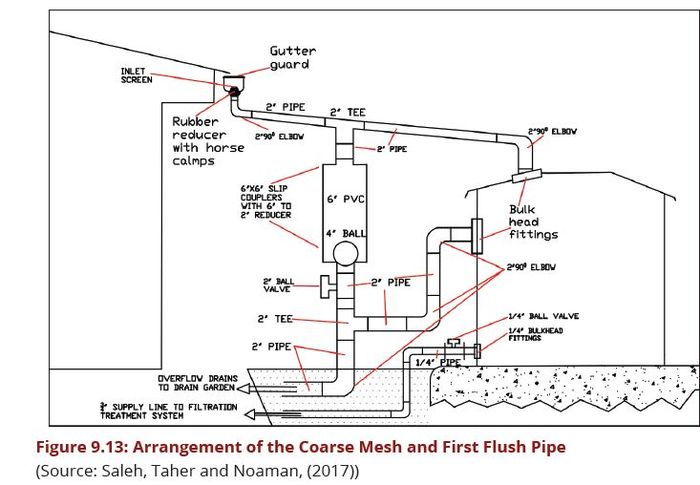

| + | The most common materials for gutters and downspouts are half-round PVC, | ||

| + | vinyl, pipe, seamless aluminium, and galvanized, steel. Regardless of material, | ||

| + | other necessary components in addition to horizontal gutters are drop outlets, | ||

| + | which route water from the gutters downward, and at least two 45-degree | ||

| + | elbows, which allow the downspout pipe to sit snugly against the side of the | ||

| + | house. Additional components include the hardware, brackets, and straps to | ||

| + | fasten the gutters and downspout to the fascia and the wall. First flush system | ||

| + | separates first rainwater contaminants namely debris, dirt, and dust that collect | ||

| + | on roofs during dry periods and prevent it from entering the storage tank. | ||

| + | |||

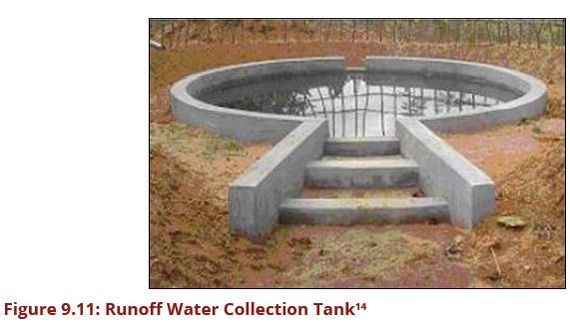

| + | ===== Surface Runoff Harvesting ===== | ||

| + | Surface runoff water harvesting is the collection, accumulation, treatment or | ||

| + | purification, and storing of storm water for its eventual reuse. It can also include | ||

| + | other catchment areas from man-made surfaces, such as roads, or other urban | ||

| + | environments such as parks, gardens and playing fields. The harvested surface | ||

| + | runoff water is an excellent alternative to replace treated water for use in other | ||

| + | purposes. If properly designed, surface runoff catchment systems can collect | ||

| + | large quantities of rainwater. | ||

| + | |||

| + | [[Image:Figure9.11.JPG|570px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| + | |||

| + | [[Image:Figure9.12.JPG|700px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| + | |||

| + | [[Image:Figure_9.13.JPG|700px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| + | |||

| + | ==== Treatment of Harvested Rainwater ==== | ||

| + | Effective and reliable water treatment is essential in protecting public health | ||

| + | and promoting consumers’ confidence in the water they receive. Rainwater | ||

| + | collection systems had historically been thought to provide safe drinking water | ||

| + | without treatment, because its collection surfaces (roofs) are isolated from | ||

| + | typical contamination sources (e.g. soil materials, rocks and sanitation systems). | ||

| + | However, contamination of waters from such sources may originate from | ||

| + | materials used to manufacture the roofing sheets and drainpipes (gutters). Other | ||

| + | sources of contaminants may include domestic and industrial dust, leaves and | ||

| + | other debris blown onto roofs. In addition, birds and climbing animals defecate | ||

| + | upon such roofs and gutters presenting risks associated with bacteriological and | ||

| + | metal contamination. | ||

| + | |||

| + | These are among the potential sources of rainwater contaminants and thus | ||

| + | preventing them from entering the storage tanks can significantly enhance the | ||

| + | quality of rainwater collected. The reduction of contaminants in rainwater tanks | ||

| + | may be brought about through different ways including: | ||

| + | (a) Takinginto consideration several environmental conditions to improve | ||

| + | rainwater quality, such as proper design, operation, and periodic maintenance | ||

| + | of collection systems,cleanliness of the catchment area and water storage | ||

| + | tank, and protection of collection systems from pollutants,<br> | ||

| + | (b) Discarding the first spill of rain (for at least 15 minutes) before collecting the | ||

| + | water,<br> | ||

| + | (c) Installation of screeners in drainpipe inlets or gutters,<br> | ||

| + | (d) Avoiding roof painting with materials likely to present health risks,<br> | ||

| + | (e) Adopting closed tanks option rather than open tanks which are prone to | ||

| + | contamination emanating from atmospheric deposition,<br> | ||

| + | (f) Disinfecting the harvested rainwater with appropriate water disinfectants | ||

| + | such as chlorine. | ||

| + | |||

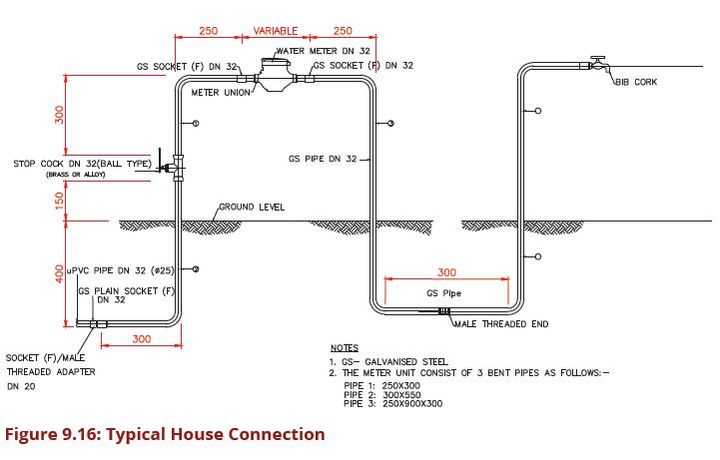

| + | ==== Water Points and Service Connections ==== | ||

| + | To achieve the Water Sector Sustainable Development Goals (SDGs), Water Points | ||

| + | (WPs), or community taps, are essential components of any new or expanded | ||

| + | water supply schemes. In peri - urban or informal urban housing areas, this | ||

| + | predominant service should as far as possible be water points. In rural areas the | ||

| + | decision on whether to install a community tap or water point (WP) should be | ||

| + | taken by the community but only after they have been fully informed on what | ||

| + | this means. In either case, water should be charged for on some volumetric basis. | ||

| + | Individuals who wish to have yard or in-house connection should be allowed in | ||

| + | return for higher payment. | ||

| + | |||

| + | Because WPs play a key role in the supply of water in rural areas and to the urban | ||

| + | poor and will continue to do so for many years to come, the most appropriate | ||

| + | guidelines should not, therefore, be rigidly followed but should be used as a basis | ||

| + | from which designers can start. | ||

| + | |||

| + | Regardless of the detail, involving the community in finding proper sites for | ||

| + | the water points has proven to be an efficient way to improve psychological | ||

| + | ownership, prevent vandalism and make treated water accessible. As the design | ||

| + | of water point is vital for its sustainability; therefore, it has to be well adapted | ||

| + | to the local context and the requirements of operators and customers. The | ||

| + | water point design has also a significant implication on the required funds for | ||

| + | construction. The user community should be consulted before deciding on where | ||

| + | to locate WPs. Use of the criteria of time to walk to WPs should be adopted with | ||

| + | an indicative time of 30 minutes (maximum). | ||

| + | |||

| + | ==== Common Types of Water Points ==== | ||

| + | * Water taps | ||

| + | * Public standpipe with super structure/kiosk | ||

| + | * Public standpipe without superstructure but has a simple shade with one or two tap points | ||

| + | |||

| + | ==== Minimum Technical Requirements of Water Points ==== | ||

| + | The utilities must ensure that the following minimum requirement for technical | ||

| + | aspects must be adhered to in order to guarantee the ergonomic and hygienic | ||

| + | aspects of water supply outlets as well as their user-friendliness in terms of | ||

| + | the movements and practices of outlet users (and of women and children in | ||

| + | particular) and operators:<br> | ||

| + | (a) No one should have to carry the water for more than 20 m in an urban area | ||

| + | and 400 m in rural areas whilst the time spent on collecting water should not | ||

| + | exceed 30 minutes elsewhere in Tanzania,<br> | ||

| + | (b) Users should be able to fill their container safely,<br> | ||

| + | (c) For water points with long operating hours, a shade, roof or shelter for sun | ||

| + | protection should be provided;<br> | ||

| + | (d) A solid slab should be installed to ensure a hygienic and safe water collection<br> | ||

| + | (e) Sufficient slope to allow natural drainage and efficient cleaning;<br> | ||

| + | (f) An elevated fetching bucket bay as lifting aid;<br> | ||

| + | (g) A soak away into the ground should be provided at the water point site to | ||

| + | ensure that the water point site is adequately drained;<br> | ||

| + | (h) A water meter for an accurate measurement of the water delivered and sold | ||

| + | at the water point site<br> | ||

| + | (i) High quality water taps to be used<br> | ||

| + | (j) Where water is only available intermittently or supply pressures are low, | ||

| + | provision of storage should be considered. | ||

| + | |||

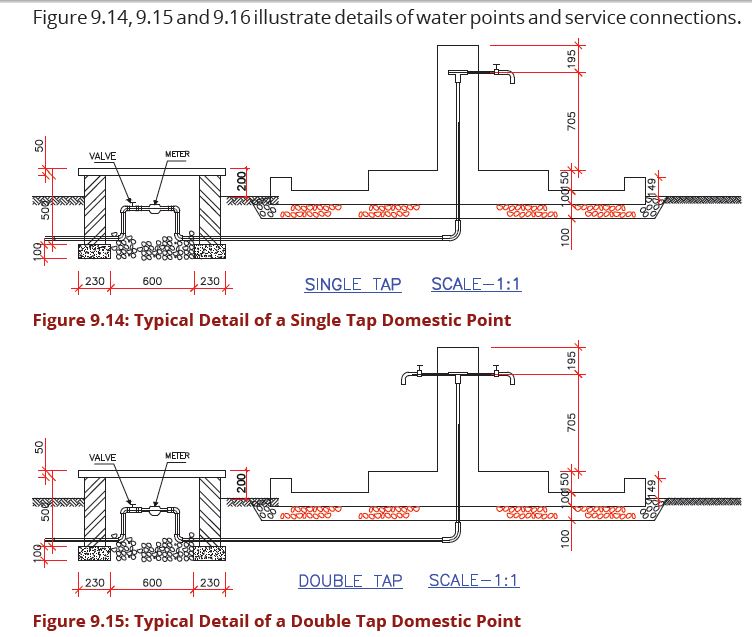

| + | ==== Criteria for the Design of Water Point/Kiosks ==== | ||

| + | (a) Water point should be designed for a water consumption of 25 l/p/d,<br> | ||

| + | (b) Design periods to be adopted: short term - 5 years; medium term - 10 years,<br> | ||

| + | (c) Satisfactory pressure at the WP/water points should be provided for: The | ||

| + | minimum static head should be not less than 6m and the maximum 25m.<br> | ||

| + | The flow from each tap at a WP should not be less than 10 l/min, and where | ||

| + | appropriate, a constant flow valve should be installed,<br> | ||

| + | (d) A single WP/Water point should in general not supply more than 40-50 | ||

| + | households, or 200 to 250 persons, which number is likely to be the minimum | ||

| + | if the supply is to be financially viable for an operator or a community,<br> | ||

| + | (e) The water quality must comply with the latest edition of Tanzanian Standards | ||

| + | (TBS) and contamination at the source should be avoided,<br> | ||

| + | (f) Acceptability: The design of the water point should be user friendly and | ||

| + | according to the minimum technical standards specified in Figures 5.4, 5.5 | ||

| + | and 5.6,<br> | ||

| + | (g) Water points structures (pre-paid taps, yard taps, etc.) should be designed to | ||

| + | be vandalism proof, e.g. by putting a concrete slab on top of the iron roofing | ||

| + | sheets or even a concrete roof,<br> | ||

| + | (h) Water at the source should be provided in sufficient quantity and the supply | ||

| + | should be regular and continuous,<br> | ||

| + | (i) Design of a water point should take into a consideration upgrading to yard | ||

| + | and house connection later,<br> | ||

| + | (j) Design should consider the most appropriate technology, which can serve a | ||

| + | high number of poor people in urban settlements at low per capita cost and | ||

| + | takes shorter time to construct,<br> | ||

| + | (k) Potential users should participate in planning and designing of the water | ||

| + | source and access to information must be guaranteed,<br> | ||

| + | (l) A water point with a superstructure is often a more convenient place to | ||

| + | fetch water since it is more hygienic; gender sensitive and allows customers | ||

| + | to interact at the water point. | ||

| + | |||

| + | ==== Location Considerations for Water Points ==== | ||

| + | (a) The water points should be accessible to all users. It is easier to guarantee | ||

| + | free and non-discriminatory access to water points for all customers if the | ||

| + | water points are placed on public land, such as a municipal land or on a | ||

| + | land that belongs to a water utility. Private landowners are potentially in a | ||

| + | position to deny access to water points which are placed on their premises,<br> | ||

| + | (b) Public participation in decisions about a water point location is an important | ||

| + | requirement. Potential water point customers know their own surrounding | ||

| + | areas best and can easily locate appropriate water point sites. This, in turn, | ||

| + | will develop a sense of ownership for the water point,<br> | ||

| + | (c) The placement of WPs must take the preferences of the operator or attendant | ||

| + | and of future customers into account, as well as the technical and commercial | ||

| + | constraints and objectives identified by the designer. In other words, a water | ||

| + | point should be placed in such a way that it can serve a maximum number | ||

| + | of customers in an efficient and customer friendly manner,<br> | ||

| + | (d) The location of water points in relation to one another should ensure | ||

| + | adequate coverage,<br> | ||

| + | (e) Water points shall be constructed on public places or private owned land | ||

| + | with written permission from the landowner, witnessed by the LGA (Street | ||

| + | Leadership),<br> | ||

| + | (f) The water point should be located strategically starting with densely | ||

| + | populated areas to less populated areas,<br> | ||

| + | (g) Notwithstanding criteria (a) to (f), the location of a water point should be | ||

| + | confirmed by the communities to be served through their Government,<br> | ||

| + | (h) The potential beneficiaries of water point services should be involved in the | ||

| + | selection of the water point location. If the location is not conducive to its | ||

| + | customers, they might consider other sources and thus abandon the water | ||

| + | point.<br> | ||

| + | |||

| + | ==== Technical Tips to Improve Water Points ==== | ||

| + | The following are practical tips concerning the design and construction of water | ||

| + | points: | ||

| + | * The soak-away: This should have a pit filled with stones to avoid breeding of infectious insects. Also, the drains should have a slope that allows for regular cleaning and unblocking, | ||

| + | * Paintwork: Only washable paints should be used; for the exterior and the interior walls of the water point, | ||

| + | * The water meter: The water meter should be placed inside the water point. A vertical meter should be installed vertically and a horizontal meter horizontally, | ||

| + | * Door, window and locks: it is important that water point doors and windows(and frames) are made of steel; strong enough to withstand vandalism or attempts of theft. Water point windows should be installed in such a way that if they are fully opened, they are parallel to the front wall of the water point. This allows for the full use of the lifting slabs, | ||

| + | * Cement works: It is important that the Utility’s supervisor is present during the mixing of cement. | ||

| + | * This is important in order to have the right mix and to prevent “sandy water points”, | ||

| + | * Making the roof water-proof: In order to make the roof water proof, it should be tarred with a sufficient quantity of Roof Compound. Experience shows that many water point roofs are often leaking, | ||

| + | * Quality Water taps: Only high quality taps and valves should be used. Do not forget that a water point tap is used hundreds of times each day. The quality requirements of a water point tap, therefore, are much higher than of a normal domestic tap, | ||

| + | * The siting of WPs: should be so that the area can be kept clean with minimum effort and there must be sufficient scope for natural drainage of wastewater. Where cloth washing slab is provided this should be not more than 20 metres from the water point, | ||

| + | * Water taps: Install the high water taps to avoid wastage of water caused by leaking taps and unhygienic conditions around the water point surroundings, | ||

| + | * The operator: or attendant should be made responsible for keeping the area clean and drained without altering any stagnant water pools, | ||

| + | * A charge: should be made for the supply of water from a WP. This should preferably be based on a coin still in wide circulation per container of 20 litres (e.g. 50/- or 100/-), | ||

| + | * In urban areas: the operator should be selected or appointed by the household representatives and the street executive officer. In urban areas,the supply is best provided through a formal structure/water point, and the operator should be encouraged to sell other non-contaminant dry goods items both to augment income and extend operating hours. | ||

| + | |||

| + | [[Image:Figure9.15.JPG|760px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| + | |||

| + | [[Image:Figure9.16.JPG|720px|link=Chapter_Nine:_Design_of_Water_Structures]] <br> | ||

| + | |||

| + | === Structural Design Of Concrete === | ||

| + | ==== Structural Requirements ==== | ||

| + | Concrete members used in water structures range from walls, slabs, roofs and | ||

| + | floors. Design of Reinforced Concrete (RC) should ensure these structures have | ||

| + | sufficient resistance to cracking, adequate strength and does not allow leakage. | ||

| + | |||

| + | ==== Methods ==== | ||

| + | Three methods or approaches are available for structural design of concrete, | ||

| + | these are listed below: | ||

| + | |||

| + | ===== Working Stress Method ===== | ||

| + | * Produces uneconomical section, | ||

| + | * Produces stable section | ||

| + | |||

| + | ===== Ultimate Load Method ===== | ||

| + | * Produces cheaper section, | ||

| + | * Produces unstable section. | ||

| + | |||

| + | ===== Limit State Method ===== | ||

| + | * Produces economical section, | ||

| + | * Produces stable section. | ||

| + | |||

| + | Detailed design steps for concrete structures are presented in Appendix D to this | ||

| + | manual. | ||

| + | |||

| + | '''REFERENCES'''<br> | ||

| + | American Ground Water Trust. (2019). Retrieved from American Ground Water<br> | ||

| + | Trust Web Site: http://www.agwt.org <br> | ||

| + | Amit Kohli and Karen Frenken (2011). Cooling water for energy generation and its impact | ||

| + | on national-level water statistics: http://www.fao.org/3/a-bc822e.pdf <br> | ||

| + | BS 8110 (1997): Structural Use of concrete, Part1: Code of Practice for design and <br> | ||

| + | construction, British Standards Institution, London 1997.<br> | ||

| + | Harter, T. (2016 (University of California, Davis) Retrieved from UC Groundwater<br> | ||

| + | Cooperative Extension Program Web Site: http://groundwater.ucdavis.edu <br> | ||

| + | Manual for Rooftop Rainwater Harvesting Systems in the Republic of Yemen. November, | ||

| + | 2017<br> | ||

| + | Ministry of Water, The 3rd Edition Design Manual for Water supply and Wastewater | ||

| + | Disposal, 2009. <br> | ||

| + | Nibedita Sahoo (2008): Design of Water Tank, National Institute of Technology Rourkela, | ||

| + | India. <br> | ||

| + | Nnaji, C.C. (2019)July. Sustainable Water Supply in Buildings through Rooftop Rainwater | ||

| + | Harvesting. In Construction Industry Development Board Postgraduate Research <br> | ||

| + | Conference (pp. 390-400). Springer, Cham <br> | ||

| + | Reynolds et al (2008): Reinforced concrete designer’s handbook, Eleventh edition, Taylor | ||

| + | & Francis, New York.USA <br> | ||

| + | S. A. Saleh, T. Taher and A. Noaman (2017), Nov. Manual for Rooftop Rainwater Harvesting <br> | ||

| + | Systems in the Republic of Yemen <br> | ||

| + | Reynolds et al, (2008): Reinforced concrete designer’s handbook, Eleventh edition, Taylor | ||

| + | & Francis, New York.USA <br> | ||

| + | Water Mission (2019): The Technical Handbook Version 1.2`,North Charleston, USA | ||

| + | |||

| + | |||

| + | Previous Page: [[Chapter_Eight:_Treatment_of_Waters_With_Special_Contaminants|Chapter_Eight:_Treatment_of_Waters_With_Special_Contaminants]] << >> Next Page: [[Chapter_Ten:_Application_Software|Chapter_Ten:_Application_Software]] | ||

| + | </div> | ||

Latest revision as of 16:31, 20 July 2022

Contents

- 1 Chapter Nine: Design of Water Structures

- 1.1 Sizing And Locating Water Structures

- 1.1.1 Tanks

- 1.1.2 Sedimentation/Settling Tanks

- 1.1.3 Break Pressure Tanks

- 1.1.4 Water Intakes

- 1.1.5 Dams

- 1.1.5.1 Engineering Classification of Dams

- 1.1.5.2 Size classification of dams

- 1.1.5.3 Feasibility investigations

- 1.1.5.4 Hydrological Analysis of the Water Catchment Area

- 1.1.5.5 Geotechnical Investigation

- 1.1.5.6 Design of Dams

- 1.1.5.7 Boreholes

- 1.1.5.8 Groundwater Prospecting

- 1.1.5.9 Structures for Rainwater Harvesting

- 1.1.5.10 Treatment of Harvested Rainwater

- 1.1.5.11 Water Points and Service Connections

- 1.1.5.12 Common Types of Water Points

- 1.1.5.13 Minimum Technical Requirements of Water Points

- 1.1.5.14 Criteria for the Design of Water Point/Kiosks

- 1.1.5.15 Location Considerations for Water Points

- 1.1.5.16 Technical Tips to Improve Water Points

- 1.1.6 Structural Design Of Concrete

- 1.1 Sizing And Locating Water Structures

1 Chapter Nine: Design of Water Structures

The main components of a water project include water intakes, break pressure tanks, water points, valve chambers and storage/sedimentation tanks. The following sections describe the design procedures for various water structures.

1.1 Sizing And Locating Water Structures

1.1.1 Tanks

1.1.1.1 Storage tanks

The primary purpose of water storage tank is to balance supply during peak hour demand. It is typical to have two peak times during the day, one in the morning the other in the evening when large amounts of water is collected. Water storage tanks should be positioned on higher ground relative to the supply area so as to command pressure.

The following design points should be considered as procedures when estimating the water tank volume/capacity

- Estimate tank capacity by calculating the water demand at various times of the day and comparing that to the yield of the water supply scheme,

- Establish the demand and supply patterns for a typical day during the assessment phase of the project

- The supply yield pattern of the project depends on the design operation period for pumping systems,

- Consider providing tanks for solar-powered projects as they have limited pumping hours,

- Establish the tank volume based on the amount of water needed from the time when there is more water leaving the tank than entering the tank (demand> supply) until the time when there is more water entering the tank than leaving it (Supply > Demand),

- Size the water tank volume so that it is able to meet the deficit during these hours,

- Calculate the volume of the tank by comparing the supply with demand at incremental time periods and balance to the existing storage,

- The balance should start at zero, then calculated for each time period (iteration) by adding the surplus or deficiency to the balance of previous iteration.

This is represented below, with n representing the iteration.

Balance n = Surplus / Deficiency n + Balance n-1

The necessary tank capacity (V tank) is then calculated as the maximum balance (V max) minus the minimum balance (V min) minus the final volume (V final).

V tank= V max – V min –V final (9.2)

Refer to Appendix C example of the sizing of tanks.

1.1.2 Sedimentation/Settling Tanks

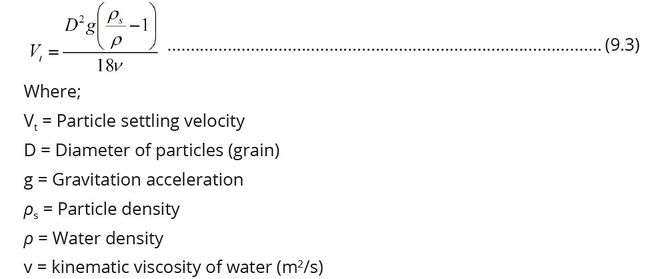

Settling Tanks and clarifiers should be sized based on the settling velocity of the smallest particle to be theoretically 100% removed. Settling velocity of particle may be determined using Stokes law:

Particle characteristics (diameter and density) may be determined in the laboratory through standard methods. Particle settling is governed by the condition that the settling velocity of a particle (Wt) should be less than the settling tank overflow rate (Vo). The settling tank overflow rate (Vo) is defined as:

Overflow rate (Vo) = Flow of water (Q (m3/s)) / (Surface area of settling basin (A)(m2)) (9.4)

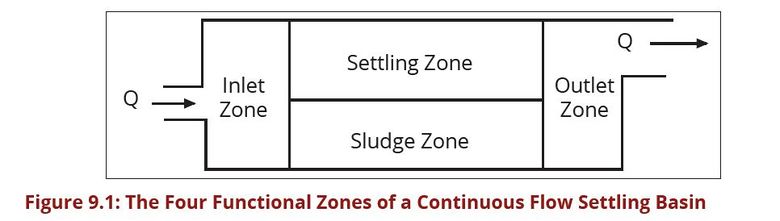

Settling tanks and clarifiers may be designed as long rectangles after calculating the surface area, rectangular shapes are hydraulically more stable and easier to control for large volumes. Factors such as flow surges, wind shear, scour, and turbulence may reduce the effectiveness of particle settling. To compensate for these less than ideal conditions, it is recommended to double the area determined from theoretical calculations. It is also important to equalize the water flow distribution at each point across the section of the basin. Poor inlet and outlet designs can produce extremely poor flow characteristics for sedimentation.

Sedimentation efficiency does not depend on the tank depth. If the forward velocity is low enough so that the settled material does not re-suspend from the tank floor, the area is still the main parameter when designing a settling basin or clarifier, taking care that the depth is not too low.

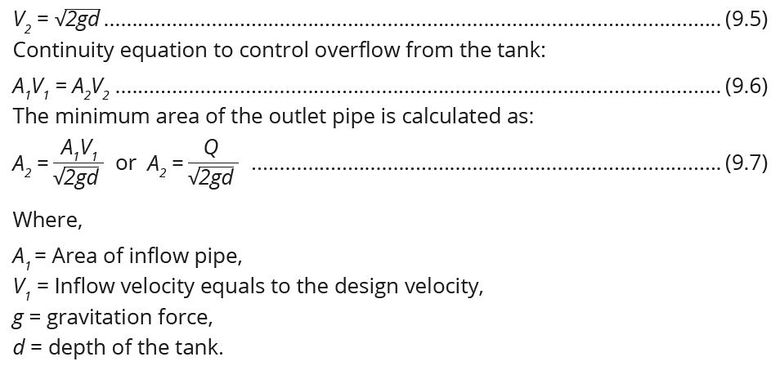

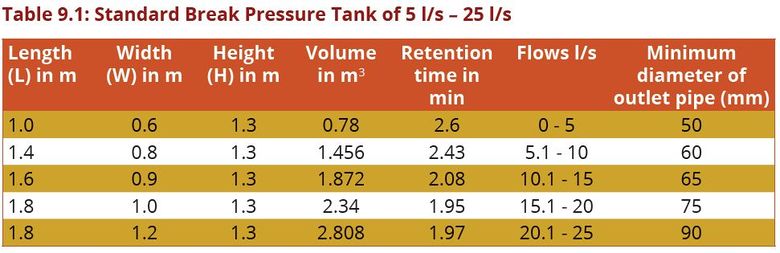

1.1.3 Break Pressure Tanks

Break pressure tank is a structure that is located between a water reservoir and supply point with the aim of reducing the pressure in the system to zero (atmospheric pressure). Conventional break pressure tank is constructed of concrete in rectangular shape with the depth of the tank about 1.2m. The design criteria for the break pressure tank is to find such that the minimum diameter of the outlet pipe can convey the design flow without causing the overflow in the tank.

Example:

Consider:

Free flow in the tank at depth d conveyed to outlet pipe at velocity V_2:

Choose the dimension of the tank at d values ranging from 1.0 m -1.5 m, length and width of the tank between 1 m to 3 m. The sizing of break pressure tank may be calculated based on the following specifications:

1.1.4 Water Intakes

This is a structure built in the body of water to draw water from the water source. The source may be a canal, river, spring, lake or dam usually built as an integral part of the source. The intake consists of an opening, a strainer or grating through which water enters and conduit conveying the water usually by gravity to a well. These structures are masonry or concrete structures and provide relatively clean water, free from pollution by sand and objectionable floating material.

a) Function of Intakes

The main function of an intake is to provide the highest quality of water from the source and to protect pipes and pumps from being damaged or clogged by wave action, floating objects/debris and submerged marine objects or creatures.

b) Consideration for Locating water intake structures

The following general considerations should be taken while designing and locating water intake structures:

- The source of supply should not have wide fluctuation in water level,

- The site selected should be able to admit water even under lowest flow conditions in the river. Generally, it is preferred that intake should be sufficiently below the shoreline,

- The proximity of the intake structure to the treatment plant,

- Good foundation, away from navigation requirements, safe from effect of floods, storms and scouring in the bottom,

- It should be placed at a location that is free from pollution. It is better to provide the intake at a location reasonably far from settlements so that the water is not contaminated,

- Away from locations with a high frequency of floating materials such as ice, vegetation and logging,

- Intake capacity must be large enough to meet the requirement of design discharge,

- It should not interfere with river traffic if any.

- It should be located where good foundation conditions are available,

- It should be located so that it admits relatively pure water free from mud, sand and pollutants.This implies protection from rapid currents,

- It should be created on the erosion side of a river bend and not the deposition side.

c) Considerations for design of various types of water intakes

(i) Reservoir intake

The water in a reservoir is likely to vary in quality at different levels. This feature makes it usually desirable to take water from about 1 m below the surface. Due to fluctuations in water level, it is desirable to have entry ports at various heights with gate valves. These gate valves are used to regulate water supply. When the water level goes down, a gate valve of a lower port is opened. Access to the ports is through an operating room.

(ii) River intakes

A river intake should consist of a port (conduit) provided with a grating and a sump or gravity well. The conduit should be supported on pillars 1-2 m above the bottom to prevent entry of silt. Also it is kept 1 m below the top surface to avoid entry of floating debris. Velocity should be kept at less than 0.15 m/s to prevent the entry of small fish. River intake structure should be constructed upstream the point of sewage disposal or industrial wastewater disposal. River intakes may need screens to exclude large floating matter. The bottom of the river intake must be sufficiently stable.

(iii) Lake intakes

If the lakeshore is inhabited, the intake should be constructed such as to minimize the danger of pollution. The intake opening should be 2.5 m or more above the bottom so that the entry of silt with water is minimized. The water entry velocity must be low to exclude floating matter, sediment, fish or ice. Entering velocity of 0.15 m/s is usually used. Offshore winds tend to stir up sediments which will be carried for long distances. So, intakes must be located at a distance of not less than 600 meters from the shoreline. Such intakes are recommended to be of multiple level intakes to ensure the source can cope with climate change impacts.

(iv) Intake conduit

Intakes located at long distances from the pumps usually deliver their water to the pump well at the shore end by gravity. This requires a large pipe or conduit so that the velocity is low. But velocity should not be too low to allow for the occurrence of sedimentation. The conduit may be a submerged pipe or tunnel. A submerged pipe should be protected by burying it in a trench, surrounding it with rock or held in place with piling.

1.1.5 Dams

A dam is a structure built across a stream, a river, or an estuary to retain water. Dams are built to provide water for human consumption, for irrigating arid and semiarid lands, or for use in industrial processes.

1.1.5.1 Engineering Classification of Dams

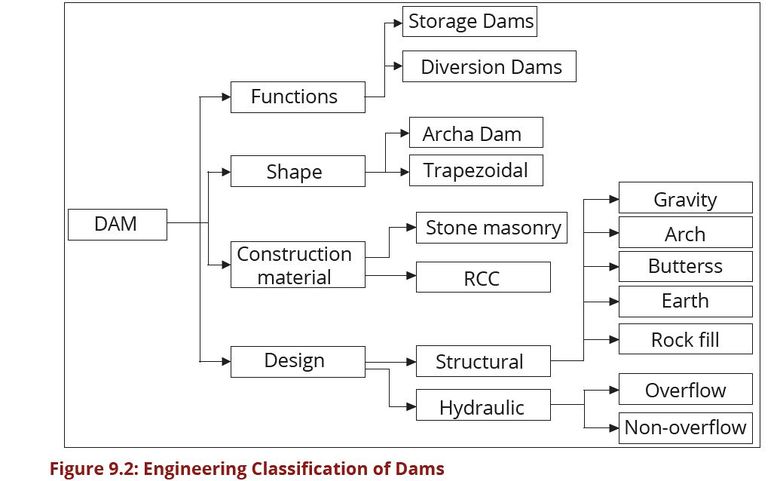

Dams are classified according to their function, shape, construction materials and design. This is termed as engineering classification. Figure 9.2 presents a typical dam engineering classification:

Under structural classification, there are several dam type namely; gravity, arch, buttress, earth fill and rock fill. The Ministry of Water has inventoried about 710 dams whose information has been recorded in a database. As per the inventory, more than 99% of these dams are earth fill and rock fill dams and the rest fall into other categories. Due to this fact, the emphasis of this manual is on earth fill and rock fill dams to guide their design, construction and Operation and Maintenance.

1.1.5.2 Size classification of dams

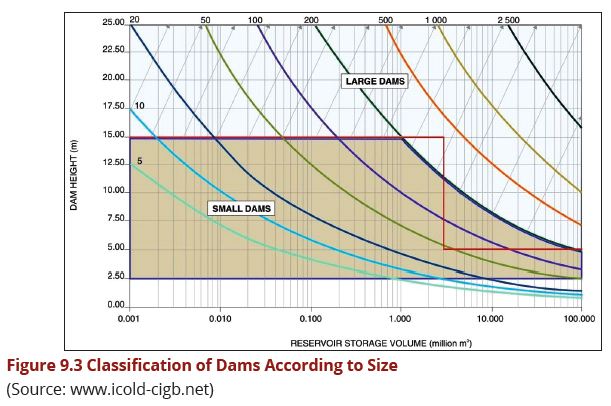

(a) Large dams

According to International Commission on Large Dams (ICOLD), large dams are

those having capacity of 3million cubic meters or more and a height of more than

5 meter as summarized by the expression below:

5<H<15m and V>3Million cubic meters.

Where:

H is height in meters above riverbed level to maximum crest level,

V is storage volume in million at Maximum Operating Level=Full Supply

Level in most cases.

(b) Small Dams

Small dams have height of less than 2.5m and the product of H2√V and should be

less than 200 as indicated here below:

2.5<H<15m and H2√V <200

Note: (*) Minimum dam height can be changed to 2 or 3 m in the case of dams in

residential or very populated areas.

Also, note: For flood retention dams holding no water the storage volume at crest

of spillway level (design storage volume) should be used.

In Figure 9.3, the ICOLD classification (www.icold-cigb.net) of dams based on size

is presented:

The focus of this manual is on large dams. Small and sand dams are covered in the rainwater harvesting guidelines prepared by the Ministry of Water and thus a designer should consult the relevant guidelines as appropriate.

1.1.5.3 Feasibility investigations

During the feasibility study all data and related information of the project should be collected and analysed. The following are the detailed guidelines for conducting feasibility studies and preliminary designs of a dam project. Note that, in this manual, the emphasis is on earth fill dam as the dominant dam type in the country.

(a) Topographical Survey

Once all preliminary investigations have been made and a suitable dam axis has

been selected, the next step is to carry out a detailed survey of the valley and

reservoir area to allow for more accurate estimates of quantities and to provide

the necessary data for appropriate design work to be undertaken. The aim of

such a survey is to present, on paper, contour map of the reservoir up to and

exceeding the maximum flood level, and to provide details for the location of the

embankment, spillway and outlet works. From the contour map, the capacity of

the reservoir can be assessed by varying dam heights.

The topographical survey works can be conducted by using different techniques

depending on the site condition, size of the catchment, availability of resources

and level of accuracy required. Light Detection and Ranging (LiDAR) survey, drone

(Aerial), Differentials GPS (Real Time Kinematics-RTK), Totals station and ordinary

levelling survey may be deployed during the topographical survey. The required

contour map should range from 0.25m to 1.0m contour interval depending on

the topographical characteristics of the area. Note that the contour interval

is directly proportional to accuracy of the estimated volume of reservoir. The

elaboration of the survey techniques used for topographical data collection and

analysis are as provided here below.

(i) Grid survey

This is a simple and straightforward but time-consuming method. It may not be

appropriate if the area is heavily vegetated and/or physically inaccessible.

(ii) Cross-sections

Cross-section surveys are taken along various lines within the river valley(s) from

benchmarks previously established. Levels are observed at set intervals and

outstanding features (changes of slope in particular) are also noted.

(iii) Spot heights

This is especially suited for larger areas. A circuit of benchmarks is established

and spot height observations with bearing, distance and elevation are made

from each station. For smaller dams, and if a theodolite or electronic instrument

is used, it may be possible to take all the readings from one station. Alternatively,

reasonably accurate GPS surveys can be used to establish a network of elevation

readings across the site.

(iv) Aerial survey

This does not have much difference from the spot heights. However, this

technique deploys plane (LiDAR) and drone to conduct topographical surveys of

the proposed dam catchment area. The major advantage of this technique is that

it is time-saving and the major disadvantage is its high cost compared to other

techniques. Therefore, this technique is more suitable for large projects.

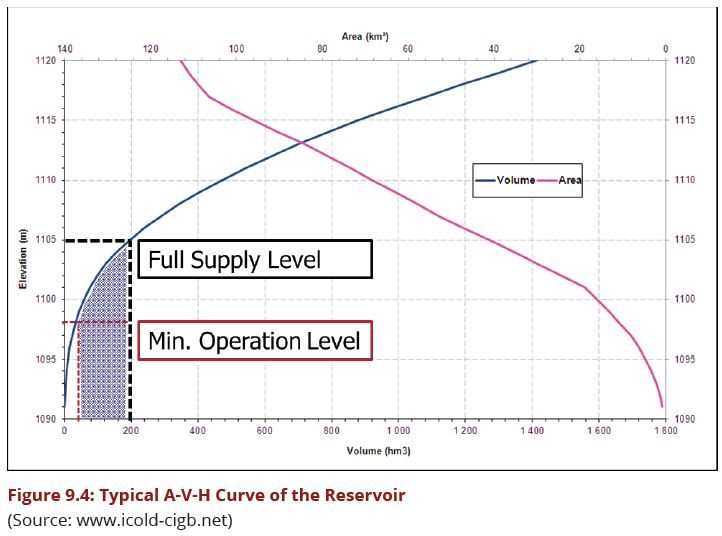

The output of the topographical map is a depth-capacity curve and can then be

drawn up to provide a quick and easy method for the dam designer to choose the

optimum full supply level. Figure 9.4 represents the area capacity depth curve:

1.1.5.4 Hydrological Analysis of the Water Catchment Area

Hydrological analysis is a very important aspect to be considered when designing any hydraulic structure. During a hydrological analysis of a catchment, three design issues should be considered which are:

- Water yield of the catchment,

- Design flood and

- Sediment accumulation in the reservoir.

In Tanzania, some of the rivers are un-gauged which calls for the use of empirical formulae in the estimation of reservoir inflows and spillway capacity of a dam. In the absence of direct measured flows of rivers, the catchment yield is estimated based on rainfall run off models.

Steps to be followed in conducting hydrological analysis of a catchment

Step 1: Determine the amount of data required for the analysis

Rainfall data is required for the probability rainfall analysis, flood analysis and

water availability analysis. For this reason, existing rainfall data from several

sources have to be collected and reviewed, including: daily rainfall, monthly rainfall,

monthly discharges, daily mean discharges and other hydro-meteorological data

which are used as part of the input rainfall runoff modeling.

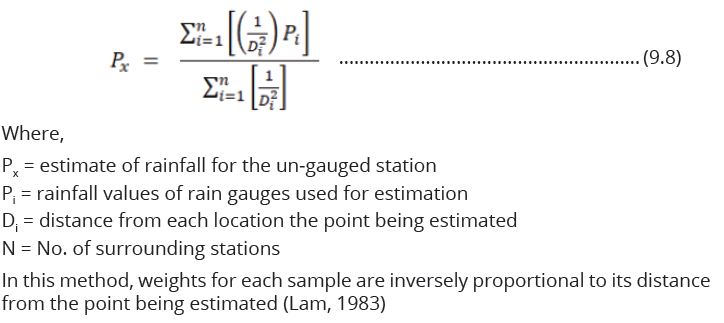

Step 2: Assessment of Watershed Rainfall Records and gap filling of rainfall

data

In watershed work it is often necessary to know the average depth of rainfall

over an area. The rainfall data used includes daily amounts as measured at rain

gauges. Rainfall data is required for probability rainfall analysis, flood analysis

and water availability analysis. Missing data may be interpolated using several

methods and in this manual Inverse Distance Squared Method is suggested to

be used and compared with other methods available in different references as

indicated below.

Step 3: Estimating Average rainfall depth

Beside other methods, Thiessen is user friendly for estimating watershed Average

rainfall depths using a rain gauge network. In the Thiessen method, the watershed

area is divided in sub areas, using rain gauges as hubs of polygons. This method

and other related approaches are explained in hydrological literature.

Step 4: Assessment of Runoff flow records

Daily river flow records collected within the catchment area and contributing to

the proposed reservoir should be used for runoff estimation.

Step 5: Rating curve

In order to transform the hydrometric levels into flow values, it is necessary to

process a rating curve for each of the stations being considered. The calculation

of the rating curve consists of estimating the parameters of a fitting function on

known pairs of level-flow values. The fitting function is specifically chosen so that

it can mathematically adapt to the experimental points. The look up function in

spread sheet should be deployed to estimate the discharge from the known pair

of level-flow. The following is the basic equation used to estimate the discharge

from water level data measured in the river.

H --> Q Q = a(H – b)c......................................................... (9.9)

1.1.5.5 Geotechnical Investigation

(a) The purpose of geotechnical investigation

The following are the purposes of geotechnical investigation for dam design and

construction:

(i) To evaluate the parameters of soil/rock at the proposed site,

(ii) To assess the engineering parameters and to estimate the safe bearing

capacity of dam foundation,

(iii) Drilling borehole in order to know the stratification and conducting necessary

field tests and to collect samples for laboratory testing,

(iv) Testing soil samples in the laboratory to determine the physical and

engineering properties of the collected samples, and

(v) Analyzing all field and laboratory data to evaluate safe bearing capacity for

given foundation sizes and necessary recommendations for foundation

design and construction materials.

(b) In-situ Tests

The level of geotechnical investigation depends much on the size of the dam

project, surface geological characteristics, topographical and geomorphological

characteristics of the site. The geotechnical investigation mainly is subdivided

into main three categories.

To obtain the geotechnical properties of the foundations of major structures

including dam, spillway and weir, the in-situ tests are carried out in the boreholes

and trench pit field test including standard penetration test and plate load test

in soil and weathered zone dilatometer test to identify strength a different

stratification of the geological formation, as well aswater pressure test in the

bedrock (Hydraulic Conductivity of the Geological formation).

Investigation of the underlying geological formation of the dam site

In order to analyze the formation of the underlying rock of the dam site, different

techniques are deployed. For small scale investigation which is conducted in

soft formation, augering is used while in hard formations deployment of heavy

equipment is highly recommended through coring. The core samples are

analyzed to determine faults and stratification of the underlying geology of the

dam and reservoir sites.

Soil Sampling for Laboratory Test

Soil sampling is conducted in order to determine mechanical and chemical

properties of the geological formation and construction materials collected from

boreholes. Recommended soil tests for design of the embankment dam are

detailed on section 12.4.4.

1.1.5.6 Design of Dams

(a) Design (Spillway Dimensioning) Flood by rainfall runoff model

The aim is to evaluate the extreme floods to be adopted for the design of a dam and

the pertaining hydraulic structures. More in detail, the hydrological elaborations

estimated are expected to satisfactorily assess the flood associated to several

return periods. Two methodologies may be adopted for the hydrological study

for the purpose of constructing hydraulic structure such as dam namely:

- Probable rainfall,

- Rainfall-runoff model.

Different distributions, including two parameters log-normal, three parameters log-normal, Gumbel and Log Pearson type-III have to be compared. It is noteworthy that since the historical runoff time sets are quite limited in some catchments, the prediction of the extreme flood with high return periods with statistical methods can lead to results on significant uncertainties.

The transformation of rainfall into runoff to estimate the peak flood and the entire hydrograph at the section of interest should be developed. The hydrological models can allow the estimating of the Probable Maximum Flood (PMF) i.e. the greatest flood physically possible over the catchment of interest.

Probable rainfall by frequency is calculated by statistical analysis on annual extreme series data. The daily maximum rainfall according to various return periods through two parameters log-normal, three parameters log-normal, Gumbel and Log Pearson type-III distribution.More information on statistical approaches can be found in appendix J.

The return period (sometimes called the recurrence interval) is often specified rather than the exceedence probability. For example, the annual maximum flood flow exceeded with a 1 percent probability in any year, or chance of 1 in 100, is called the 100-year flood. In general, Xp in the T-year flood is computed as follows

T = 1/ (1-p) .......................................................................... (9.10)

After geotechnical investigation and soil testing, hydrological analysis, sediment analysis, detailed topographical survey and Environmental and Social Impact Assessment the following stage is to conduct a detailed design and cost estimate of the project. The cost of the project should form a basis for economic analysis of the entire project. During economic analysis of the project the cash flow is prepared which defines the payback period of the project. This chapter is not prepared to guide the users on project economic analysis since the matter is covered in other chapters of the manual.

The design section focuses on earth fill and rock fill dams and other types of dams may be designed using international guidelines.

(b) Reservoirs, Dams and their Spillways

Reservoirs

A reservoir is required when the minimum daily design flow at the intake site plus

any minimum compensation release requirement is less than the average

daily demand. It is a basin constructed in a valley of the stream. For storage of

water, weirs may be constructed if the difference is small but if the difference is

appreciable, an earthen dam, masonry, rock fill, concrete dam may be constructed

across the stream for storage

Site Selection

Site selection criteria have been defined in the pre-feasibility study and more

elaborated in feasibility study section. Therefore, the design section deploys

the information gathered from other studies of the project and are highlighted

below.

The site for an upstream or mainstream Reservoir and its Dam should be selected such that it may command the entire area without pumping. The following main features should be considered for the selection of a site of such an impounding reservoir:

(i) It should be on impermeable strata, i.e. permeability coefficient (k) should

be less than 10-7 m/sec.

(ii) A narrow opening in the valley should be selected to reduce the length of

the dam.

(iii) Objectionable salts and minerals soluble in water should be absent from the

reservoir site so that the water is of acceptable quality.

(iv) The land to be submerged should be relatively unoccupied and cheap, i.e.

involve least compensation and observe laws of environment conservation.

(v) The land should be free of marshy layers and vegetation which could affect

the colour, odour and taste of water.

(vi) The slopes of the basin should be steep so to reduce the surface area per

unit of volume in such a way that both undesirable shallow water and surface

evaporation can be minimized.

(vii) The valley of the stream in which the dam is to be constructed should be

rapidly widening upstream of the dam so that it may afford the greater

average volume per metre height and length of the dam.

(viii) The capacity of the reservoir should be such that it will ensure the total

demand of water for the town to be delivered continuously. The capacity

depends upon the climatic conditions of locality and the period of dry

weather.

(ix) The dam site should not be located over a fault line parallel to the stream

bed.

(x) The storage capacity in regions of dry climate, long droughts and infrequent

rains will be more than that of the regions of moist climate and of frequent

rains, and an initial estimate can be made using Hawksley’s rule.

D = 1600/√F ....................................................................... (9.11)

Where:

D = the number of days for which the supply is to be stored,

F = the mean annual rainfall of three consecutive dry years expressed in cm.

(xi) If the stream brings large quantities of silt, debris, etc., the storing capacity

will be reduced due to considerable accumulation. It should be taken into

account by providing extra storage (called dead storage) which is normally

1/4- 1/5 of the total storage. The actual amount of dead storage depends on

the silt load and design period adopted. As far as practicable, silting should

be controlled. The sediment analysis of the reservoir should be computed

based on the available information from the manual. Details of other design

steps are presented in Appendix K.

1.1.5.7 Boreholes

1.1.5.7.1 Groundwater Analysis

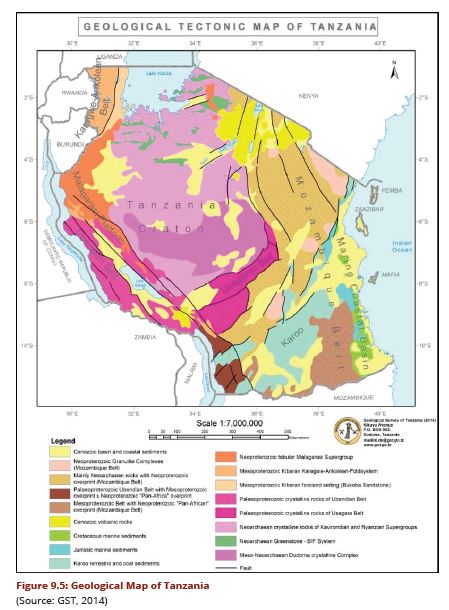

(a) Geology

Geological information is of great value to every hydrogeologist, as it indicates

the extent of water bearing layers and less pervious layers, both in a horizontal

and in vertical direction. A simplified geological map of Tanzania is shown in

Fig. 9.5, together with its key.

Hydrogeologically, rocks may be considered as falling into one of the two groups

as follows:

(i) Sedimentary rocks

These rocks are the result of eroded sediments from source rocks. Sedimentary

rocks are composed of silicate, carbonate and clay minerals. The rocks rarely

occur as single units and younger beds are usually laid down upon older ones.

However, the sequence may be disturbed or extensively folded and faulted.

The occurrence of groundwater in sedimentary formations is generally found in sandstones, carbonates and unconsolidated materials. The sandstone formations are rated as highly productive aquifers due to both their primary and secondary porosity and permeability. The Calcareous formations are also good aquifers due to solution process taking place at later stages (karstification). Unconsolidated formations are regarded as good aquifers due to both weathering and depositional processes resulting in the formation of sand dunes, alluvial fans, floodplains, buried river channels, etc.

(ii) Igneous and metamorphic rocks

Igneous rocks may be classified into two types: extrusive and intrusive. In extrusive

rocks (volcanic) such as tuff, andesite, basalt, etc., water occurs in fractures and

pyroclastic materials. The intrusive and metamorphic rocks termed as hard rocks

are mainly granites and gneisses, respectively. They are solid and non-porous but

can hold water in networks of cracks, joints, fractures or faults or along contacts

between rocks of various types, as in the case of dikes and sills.

Fine grained igneous rocks, e.g. aplites can be good aquifers because they have short and narrowly spaced fractures. While coarse grained rocks like granites, have long and widely spaced fractures forming a mosaic of splinths. The storativity is reasonably good between the splinths. Basic intrusive rocks, e.g. diorites and gabbros have low and tend to be poor aquifers.

(b) Hydrogeological considerations

The water resources study of the hydro-geological conditions of the project area will

indicate the viable sites for well exploration in terms of supply capacity and

water quality. Hydro-geological studies should be conducted by knowledgeable

professionals or drillers, who assess available information on existing wells.

Professionals should examine well data such as

- water quality,

- well yield,

- seasonal fluctuations,

- water table depth, and

- well drilling logs showing geologic layers.

A geo-resistivity survey of the areas being considered for possible well sites will indicate the depth and thickness of aquifers.

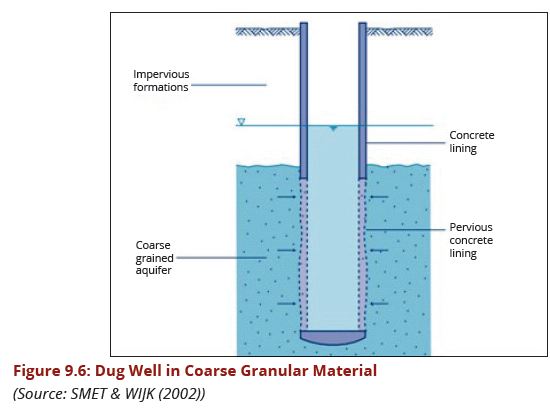

Wells can be designed and constructed in a number of ways depending on the geological condition, budget for the construction and the desired capacity of the well. The following are the types of wells that can be identified based on the construction methods employed.

(i) Dug wells

Dug wells are holes or pits dug manually into the ground to tap the water table.

The dug well may be up to 15 meters deep, with diameter usually ranging from

1 meter to 1.5 meters. The well is usually lined with concrete masonry, bricks,

stones, or reinforced concrete to prevent the wall from caving in. At depths of the

aquifer layer, the wall is embedded with slots; or prefabricated concrete caisson

rings are installed for the passage of groundwater into the dug well. Dug wells

are normally circular in shape (Figure 9.6). This type of well is sometimes capable

of drawing sufficient supplies of water from shallow sources but is easily polluted

by surface water.

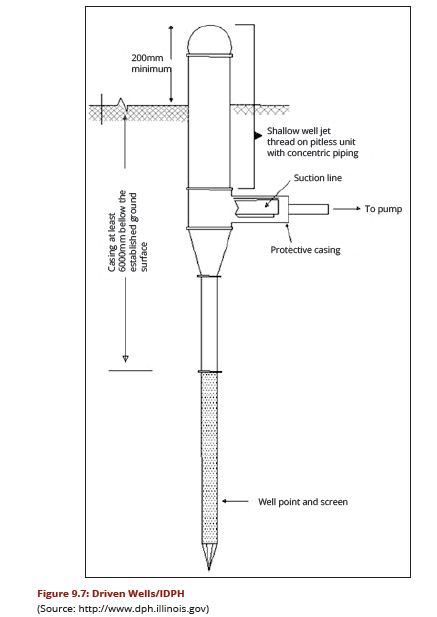

(ii) Driven wells

Driven wells are like dug wells, in the sense that they tap the shallow portion of the

unconfined aquifers (Figure 9.7). They are easy and relatively inexpensive to

construct in locations with unconsolidated formations that are relatively free

of cobbles or boulders. The wells are constructed by driving to the ground an

assembly of Galvanized Iron (G.I) pipe and a pointed metal tube called a “well

point”. The pointed end of the well point, which is the penetrating end, has

screens or holes to allow the passage of water.

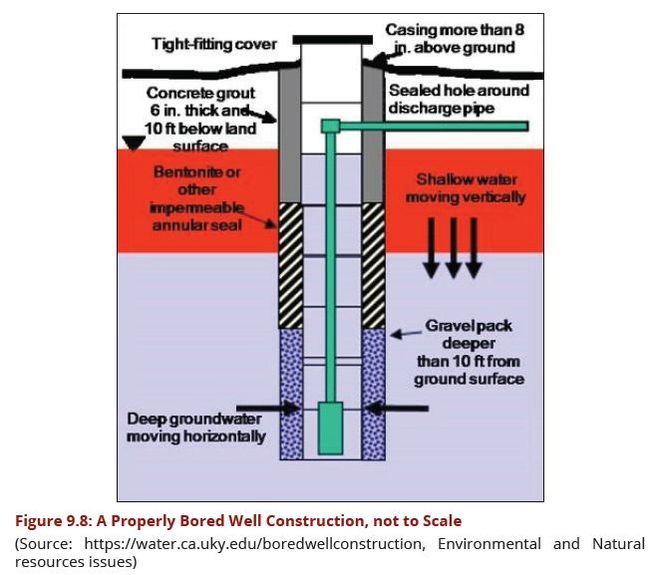

(iii) Bored wells Bored wells are constructed with hand or power augers, usually into soft cohesive or non-caving formations that contain enough clay to support the boreholes. The depth of bored wells could be up to 15 metres. Bored wells are very prone to surface contamination. The well construction method is not applicable on hard consolidated materials and is not advisable on predominantly boulder formations. Figure 9.8 shows a properly bore well.

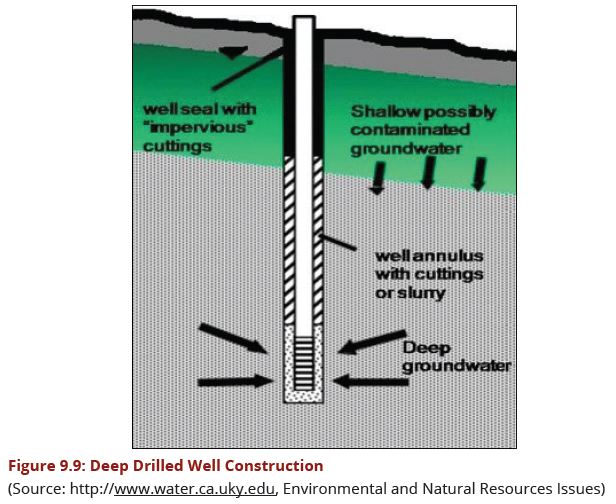

(iv) Deep drilled wells

Deep Wells drilled by professional drillers with the appropriate experience and

equipment can extract groundwater from a much deeper level than the other

types of wells. Various well drilling methods have been developed because

geological conditions range from hard rock such as granite and dolomite to

completely unconsolidated sediments such as alluvial sand and gravel. Particular

drilling methods have become dominant in certain areas because they are most

effective in penetrating the local aquifers, thus offer cost advantages.

1.1.5.8 Groundwater Prospecting

(a) Required data

Prior to carrying out hydrogeological and geophysical investigation a thorough

analysis of previous work should be carried out at the survey area. The activities

will include the use and interpretation of available data of the survey area.

Available data can be present in the form of maps, aerial photographs, satellite

imagery and drilled boreholes.

(i) Topographical maps

Topographical maps are used to show the physical features of the land.

(ii) Geological maps

This is an important tool normally used to give in some representative vertical

sections an indication about the lithology of the layers present. It is of great help

for the hydrogeological investigation.

(iii) Hydrogeological maps

These maps should show all the hydrogeological features of the area concerned.

(iv) Archived Satellite Imagery

Archived satellite imagery, much of which is increasingly available at little or no

cost is another important source of useful information. There are other maps

such as Soil Maps, Aerial Photographs as well as some others with special features

which may give valuable hydrogeological information.

Other data

(v) Water quality data

Information regarding the quality of the groundwater should be collected.

(vi) Data on different hydrological parameters

Records on discharges of rivers and streams, others on meteorological data such

as rainfall, evaporation, etc., as far as they could be of help for the hydrogeological

investigations envisaged, should be collected.

(vii) Information on wells and springs

Information about any previous drilled boreholes is of great help in knowing

groundwater potential areas. Also springs in the area should be measured and

the records be kept in an archive.

(viii) Data on borings

Information about the composition of the ground and water obtained from

samples taken from a borehole should be collected.

(b) Reconnaissance survey

The hydrogeologists should check geological structures and extent of the

catchment areas. These evidences are the key elements focus on while selecting

the best site recommended for drilling.

(i) Geological survey

Geological survey aims at identifying the visible surface geology of the area and

its surrounding, including identification of topography, physical features, soil

type, vegetation and drainage, rock outcrops, strike/dip of rocks etc. Geological

survey helps to provide a model of historical development of an area with respect

to geological time.

(ii) Hydrogeological survey

Generally, the occurrence of groundwater in hard rocks i.e. igneous and

metamorphic formation is largely limited to secondary features such as fractured

/ weathered/shear zones or faults. The potentiality of weathered zones depends

on the degree and depth of saturation and associated fracturing are normally

the groundwater controls. Recharge in this formation is by rain water infiltration

through the superficial formation, shear or weathered rocks and fractures.

Shear/ weathered or fractured zones are the expected aquifer points in the

surveyed area.

(c) Geophysical methods

Geophysical surveys are a relatively cheaper and faster way in groundwater

investigation compared to drilling of exploratory wells. This is the reason why

geophysical surveys are applied in the preliminary stages of investigations.

However, geophysical surveys require specialized professionals (Geophysists

or Hydrogeologists) to execute the surveys and to interpret the results. Several

methods are used in hydrogeology depending on the geological formation as

described below:

(i) Geo-electrical resistivity soundings

With the resistivity method normally an electrical current, generated by an artificial

source, is sent through the ground by means of two current electrodes at the land

surface. The resulting electrical potentials are measured with two other electrodes,

also at the land surface. Since rock types have different electrical properties

depending on their density, pore fluids, porosity etc., the strength of the current

applied gives a measure of the apparent resistivity of the rock. By varying the

distances between either the current electrodes (Schlumberger arrangement,), or

both types of electrodes (Wenner arrangement) apparent resistivity at different

depths and layer thicknesses are obtained. The wider the spacing distance, the

deeper the layers involved in transmitting the electrical current.

The major advantage with the resistivity method as far as ground water

investigations are concerned is that it gives direct indications of the presence of

water as resistivity is a function of water content of the rocks. Other geophysical

methods tend to provide indirect indications.

(ii) Electromagnetic (EM) methods

This method is cheap and fast, as it does not involve extended walking with

electrodes as for the case of resistivity. The methods rely on the measurement of

secondary magnetic fields generated by conducting bodies in the ground when

subjected to primary signal. The principle is that a time varying low frequency

electromagnetic field is generated by a transmitter at the land surface, which

later is transformed by an electrical conductor underground. The method is

useful in detecting buried conducting bodies such as fractured fault zones, dikes

etc. This method may also be used in detecting polluted groundwater or, fresh

water/brackish water interface.

(iii) Magnetic method

Magnetc profiling is used to measure the variation of the total magnetic field in

relation to geology along the profiles. The magnetic field of fractures/features,

dykes system and deeply weathered zone differs considerably from surrounding

rocks. The changes are increase or decrease in the normal field of the area.

(iv) Seismic methods

The method has limited direct use in groundwater exploration. However, it is

useful in determining the depth to the bed rock. The methods makes use of the

elastic property of rocks. The seismic waves are generated on the ground by

explosion or any other instantaneous release of energy into the earth.

1.1.5.8.1 Drilling

After the survey, the drilling work in areas that look promising follows. It is the duty of the hydrogeologist to supervise all drilling activities and provide technical advice in the course of drilling. Another responsibility is the analysis of rock cuttings, identification of the productive zones and recommending the borehole depth. During drilling, drillers must keep a detailed log of the drill cuttings obtained from the advancing borehole. In addition, after the drilling has been completed but before the well is installed, it is often desirable to obtain more detailed data on the subsurface geology by taking geophysical measurements in the borehole.

(a) Drilling Methods

There are several different types of rigs available for drilling water boreholes.

They vary in size, capacity and capability depending on the type of formation

expected and the depth required. There are rigs which do not perform well in

hard rock formations and there are those that are multipurpose. Percussion and

rotary-percussion drilling methods are generally the most applicable techniques

for drilling in igneous and metamorphic rocks. If a significant thickness of granular

or other overburden materials is present, a combination of methods can be

effective, although not very practical. Cable-tool, hydraulic-rotary percussion and

air-rotary percussion (down-the-hole air hammer) and foam drilling modifications

are the most common types of equipment in use today for such rock types

(Referred to web: resvol.design).

(b) Borehole Logging

(i) Rock sampling

Rock cuttings are collected, normally at a 2 meters interval while drilling is in

progress and a proper borehole log is kept. The samples are analysed to identify

the water bearing zones, and the driller keeps a record of penetration rate to

assist in identifying the hard formations and their thickness as well as recording

the water struck levels.

(ii) Down-hole logging

For accurate description of the penetrated strata, application of geophysical

logging methods assist in the determination of thickness of formations, the zones

of highest porosity and water quality.

1.1.5.8.2 Siting of Well/Borehole

The borehole siting methodology should be adjusted to the hydrogeological conditions and the local experience and should be done by an experienced hydrogeologist. It should include the following steps:

- Identification of fracture zone on aerial photographs, satellite images and maps;

- Identification of fracture zones in the field using resistivity profiling, Electrical profiling, and

- Vertical Electrical Sounding (VES).

1.1.5.8.3 Well Design

Well design is done in two stages, the preliminary design and the final well design.

Designing consists primarily of deciding the well depth, casing diameter, screen

type and slot size and its position in the well. Once the well site is determined,

a preliminary well design is prepared by an experienced hydrogeologist or

driller based on hydro-geologic information gathered before the drilling. This

preliminary design is the basis of the well drilling contract and the cost estimates.

During the drilling period, the preliminary well design will be adjusted based on

actual observations and findings on the specific site. This adjusted design will

then become the final well design. During this stage, the design assumptions

used are verified and become actual design parameters, such as water table

level, drawdown, depth and thickness of the geologic layers, types of material of

each geologic layer encountered, and other relevant information.

The main objective of the design is to construct a well that:

(a) Is structurally stable;

(b) Is able to extract groundwater at the desired volume and quality;

(c) Has the proper and correctly placed screens or slots to tap the productive

aquifers as well as to allow effortless flow of ground water into the well;

(d) Has enough space to house pumps;

(e) Has appropriate gravel packing that minimizes entry of sediments and sand

particles.

1.1.5.9 Structures for Rainwater Harvesting

1.1.5.9.1 Roof Catchment

Following details are available:

Catchment: Rooftop

Area of the catchment (A) = 100 sq. m.

Average annual rainfall (R) = 611 mm (0.61 m)

Runoff coefficient (K) = 0.85

Family size = 5

Per capita household water requirement = 25 litre/person/day

a) Calculate the maximum amount of rainfall that can be harvested from the

rooftop:

Annual water harvesting potential, S = 0.85 x 100 x 0.61 = 51 cu. m (51,000 litres)

b) Determine the tank capacity: This is based on the dry period, i.e., the period