Difference between revisions of "Chapter Twelve: Design Standards and Specifications"

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | = Chapter Twelve: | + | = Chapter Twelve: Design Standards and Specifications = |

| − | + | == Design Standards == | |

| − | == | + | <div style="text-align: justify"> |

A Standard is a limit of a measure of quality of a product prepared for judgement | A Standard is a limit of a measure of quality of a product prepared for judgement | ||

and compliance by an authoritative agency, professional or a recognized body.<br> | and compliance by an authoritative agency, professional or a recognized body.<br> | ||

| Line 30: | Line 30: | ||

Standards (TBS) | Standards (TBS) | ||

| − | == | + | == Specifications== |

Specifications is a detailed description of how work is to be performed or | Specifications is a detailed description of how work is to be performed or | ||

requirements achieved, dimensions met, materials used. These are standards | requirements achieved, dimensions met, materials used. These are standards | ||

| Line 47: | Line 47: | ||

the needs of particular works. | the needs of particular works. | ||

| − | == | + | == Materials== |

=== Building Materials=== | === Building Materials=== | ||

| Line 209: | Line 209: | ||

methods as provided in code of practice DIN 15018 or BS449 (1978/1984). | methods as provided in code of practice DIN 15018 or BS449 (1978/1984). | ||

| − | == | + | == Soil Test == |

===Methodology of Conducting Soil Investigation for Borehole and Test Pit === | ===Methodology of Conducting Soil Investigation for Borehole and Test Pit === | ||

There are several methods of soil investigation for engineering purposes.<br> | There are several methods of soil investigation for engineering purposes.<br> | ||

| Line 359: | Line 359: | ||

The soil must be tested for Chemical concern concrete works such as content of Sulphate, pH value, Sodium chloride and impurities which lower the strength of concrete during hardening. | The soil must be tested for Chemical concern concrete works such as content of Sulphate, pH value, Sodium chloride and impurities which lower the strength of concrete during hardening. | ||

| − | == | + | ==Occupational Health and Safety == |

In all water supply projects implemented by any funding sources the working environment at the sites will have to comply with the Occupational Health and Safety (OHS) Act (2003), OSH Policy (2010), OSH rules of 2015, 2017, 2018 and any subsequent amendments. These can be accessed on the MoW Website - http://www.maji.go.tz/. | In all water supply projects implemented by any funding sources the working environment at the sites will have to comply with the Occupational Health and Safety (OHS) Act (2003), OSH Policy (2010), OSH rules of 2015, 2017, 2018 and any subsequent amendments. These can be accessed on the MoW Website - http://www.maji.go.tz/. | ||

| − | + | </div> | |

'''REFERENCES'''<br> | '''REFERENCES'''<br> | ||

https://www.academia.edu/37842758/Determination_of_the_Flakiness_and_the_ | https://www.academia.edu/37842758/Determination_of_the_Flakiness_and_the_ | ||

Latest revision as of 16:42, 20 July 2022

Contents

1 Chapter Twelve: Design Standards and Specifications

1.1 Design Standards

A Standard is a limit of a measure of quality of a product prepared for judgement

and compliance by an authoritative agency, professional or a recognized body.

According to (Business Dictionary, 2020) Standards can be classified as:

- Government or statutory agency standards and specifications enforced by law,

- Proprietary standards developed by a firm or organization and placed in public domain to encourage their widespread use, and

- Voluntary standards established by consultation and consensus and available for use by any person, organization, or industry.

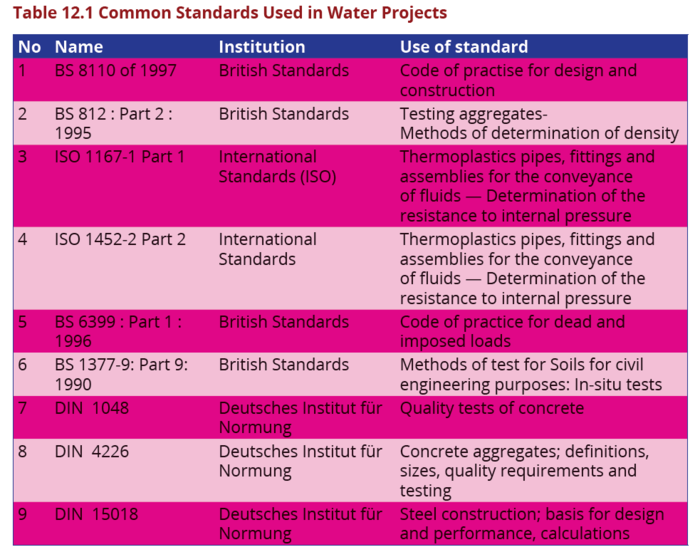

Once established, standards (like bureaucracies) are very difficult to change or dislodge. Standards that apply for water supply and sanitation projects will be as set by the Tanzania Bureau of Standards, and relate to construction works British standards .

The list of institutions whose standards are recommended to be used in designing

water projects is shown below:

- Tanzania Bureau of Standards

- British Standards (BS)

- American Society for Testing and Materials (ASTM)

- Deutsches Institut für Normung (DIN)

- German institute for standardisation

- American Association of State Highway and Transportation Officials(AASHTO)

- European Standards(ES)

For projects with requirements that are not covered by the above recommended standards, the designer should seek approval from the Tanzania Bureau of Standards (TBS)

1.2 Specifications

Specifications is a detailed description of how work is to be performed or requirements achieved, dimensions met, materials used. These are standards to be followed and tests carried out for the related product to meet acceptance criteria.

Specifications are normally drafted by the client to suit the need for a particular

work, for the purpose of construction of water projects standard specifications

have been prepared for various woks as follows:

- Standard Specifications for Civil Works,

- Standard Specifications for Electrical works,

- Standard Specifications for Mechanical works and

- General Specifications.

These documents can be downloaded from Ministry’s Website customized to fit the needs of particular works.

1.3 Materials

1.3.1 Building Materials

Building materialis any material used for construction purposes such as wood, cement, aggregates, metals,sand, bricks, steel, concrete, and clay. These are the most common types of building materials used in construction.The choice of these is based on theircost effectiveness for building projects. Appropriate materials help to guard the designed facilities against wear and tear, corrosive compounds or chemicals.

1.3.2 Materials Testing

Before materials are used for the construction of works, it is imperative for the contractor or the PE to conduct appropriate tests as per applicable standards indicated above. The following are the minimum tests proposed which should be conducted on various construction materials.

1.3.2.1 Aggregates

The test of aggregates explained below includes both fine and coarse aggregates.

Flakiness indextest

Flaky particles are those whose least dimension is 0.6 times lesser than the mean

size. The thickness of these particles iscomparatively smaller than for the other

two dimensions.

The maximum allowable limit of the flaky particles in amix is 30%. If it exceeds this value then the mix is considered unsuitable for construction purpose. The flakiness index is the percentage by weight of flaky particles in a sample. The flakiness index is calculated by expressing the weight of flaky particles as a percentage of the total weight of the sample, test procedure is as outlined in BS – 812,1995.

Elongation index test

Elongated particles are particles having length considerably larger than the other

two dimensions. One such dimension is 1.8 times greater than the other two

dimensions. The maximum allowable limit of the flaky particles in the mix is 30%.

If it exceeds this value then the mix is considered unsuitable for construction

purposes.

An elongation index is the percentage by weight of elongated particles in a sample. The elongated Index is calculated by expressing the weight of elongated particles as a percentage of the total weight of the sample, test method is expalined in BS – 812,1995

Flaky and elongated particles lower the workability of concrete mixes due to the high ratio of surface area to volume. The presence of flaky and elongated particles may also cause inherent weakness in concrete with possibilities of breaking down under heavy loads.

Abrasion (Los Angeles Abrasion Test)

Abrasion test is the measure of aggregate toughness and abrasion resistance on

crushing, degradation and disintegration. A test for abrasion is conducted based

on BS 812: Part 113: 1990.

Organic impurities test

Sand should be checked for the presence of organic impurities such as decayed

vegetation, humus, and coal dust as these affect the quality of concrete. Tests for

organic impurities should be conducted as per. BS 812: Part 4: 1976.

Aggregate crushing value (ACV) test

Aggregate crushing value test on coarse aggregates is a relative measure of the

resistance of an aggregate crushing under gradually applied compressive load.

The method for determination of Aggregate Crushing Value (ACV) is the Code: BS

812 Part 110, 10% finer test.

The 10 per cent Fines Aggregate Crushing Value (10 % FACT) is determined by measuring the load required to crush a prepared aggregate sample to give 10 per cent material passing a specified sieve after crushing. Test procedure is outline as per code BS 812: 1990 Part III.

Impact resistance value (AIC) test

The aggregate impact resistance value is a measure of resistance to sudden impact

or shock, this value may differ from resistance to gradually applied compressive

load. The procedure of Aggregate impact resistance value is provided in code BS

812 : Part 112 : 1990.

Grading – sieve analysis test

This is classification of a coarse-grained soil based on the different particle sizes

it contains. This aspect is important as it indicates the compressibility properties,

shear strength and hydraulic conductivity. The standard gradation and sieve

analysis test is: BS 812: Section 103.1: Sieve Analysis of Fine and Coarse Aggregates

Absorption test

Water absorption is a measure of the porosity of the aggregates. It gives an

indication of the strength of the aggregates. When more water is absorbed,

the aggregates is more porous in nature and generally considered unsuitable

unless found to be acceptable based on strength, impact and hardness tests. The

standard method for Testing aggregates to water absorption test is according

to BS 812-120:1989.

Specific gravity test

The specific gravity of aggregate is the ratio of its mass to that of an equal volume

of distilled water at a specified temperature. The standard method for Testing

aggregates to determine the density is BS 812 : Part 2 : 1995.

Chemical content (pH, Chloride and Sulphate)Test

This test aims at establishing permissible levells of chlorides and sulfates in

aggregate, high levels of chemicals may result in deterioration of concrete

by corrosion of steel reinforcement.Corrosion of steel affects service ability and

strength of concrete structures. The test to determine the content of chemicals

in aggregates is conducted as per BS 812-Part 117 & 118:1988.

1.3.2.2 Water

Impurities test

Water for washing aggregates and for mixing concrete shall be in accordance

with DIN 4030 and DIN 1045 and shall be clean and free from objectionable

quantities of organic matter, alkali, salts and other impurities. When TBS adopts

the new standards that are under review as of now, the Tanzanian standards will

be adopted.

Chemical content such as chloride, ph values, sulphate

Samples of the water being used or which is proposed to be used for mixing

concrete shall undergo testing for quality to determine the concentration of

sulphates and chlorides, which shall be such that the concrete mix as a whole

complies with the specified limit for salt content. Chemical content in water may

be determined through procedure explained in the code APHA 21st:2005 / ICP

OES.

1.3.2.3 Cement

Setting time test

The settling time is the time required for cement to convert from a plastic paste

to a non-plastic and rigid mass. The cement settling time is determined through

procedures explained in the AASHTO T 131 and ASTM C 191: Time of Setting of

Hydraulic Cement.

Compressive strength test

The compressive strength of cement is the measure of the strength it provides

to the mix after it has hardened .The test enables one to identify the quantity of

cement required and how much strength it will provide. The compressive strength

of cement is a basic data needed for mix design. Cement, basically identified by

its compressive strength as grade 53 grade, 43 grade, 33grade of cement. The

test procedure to is as per code of practice BS EN 196-1:2005.

1.3.2.4 Concrete Works

Tests conducted for concrete includes:

Slump test

Concrete slump test or slump cone test is done to determine the workability or

consistency of concrete mix prepared in the laboratory or at the construction site

when undertaking concreting. Concrete slump test should be carried out from

batch to batch to check the uniform quality of concrete during construction.

The slump test is carried out as per procedures mentioned in ASTM C143 in the

United States, and EN 12350-2 in Europe.

Compressive strenght test:

Compressive strength of concrete is the measure of the Compressive strength

which is the ability of the material or the structure to carry the loads on its surface

without any cracks or deflection. Standard testing methods for Compressive

Strength of Cylindrical Concrete Specimens is carried out using the procedure as

stated in the American Society for Testing Materials ASTM C39/C39 M.

Concrete voids test

This test method is related to the susceptibility of the cement paste portion of the

concrete to damage by freezing and thawing. The test estimates the likelihood

of damage of concrete due to cyclic freezing and thawing. The parameters of

the air-void system of hardened concrete can be determined by the procedures

described in the code AASHTOT 269.

1.3.2.5 Steel

Tensile strength

The tensile strength of steel is the measure of maximum amount of stress that can

be taken before failure. Tensile strength should be conducted as per standards

methods as provided in code of practice DIN 15018 or BS449 (1978/1984).

1.4 Soil Test

1.4.1 Methodology of Conducting Soil Investigation for Borehole and Test Pit

There are several methods of soil investigation for engineering purposes.

(a) Borehole drilling method

This method used to collect soil materials from underneath by using Rig

machine, heavy duty hand auger and light set hand auger. The diameter of

the borehole ranges from 150 mm to 180 mm depending on the size of the

bit used during drilling, the following should be observed:

(i) Visual soil classification and texture should be recorded,

(ii) Water table should be observed and recorded,

(iii) Depth should include the collection of soil material at different depths

depending on changes in soil materials to be recorded.

(iv) Labelling of the soil collected at each depth and include its classification

(v) Collection of soil materials and keep in plastic bags to avoid moisture

content

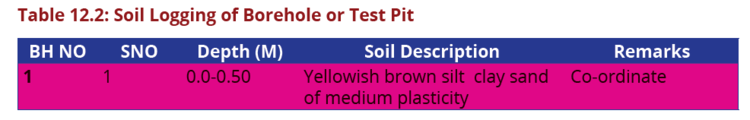

(vi) Soil logging or profile should be shown as in the table below.

(b) Test pit excavation method

This method includesthe digging of test pits with the following dimensions, 1.0 m

x 1.5 m to the maximum depth of 2.0 m.The depth depends on hardness of the

soil materials or hard rock.The equipment used for this method can be backhoe

excavator, hoes and chisels.The collection of soil materials depends on the type

of materials as mentioned for the borehole above including soil logging table.

1.4.2 Soil Investigation for Dams

In dam construction projects soil investigation, collection and classification should be done as in the following sections,

a) Along dam axis

The bore holes or test pits should be conducted along the dam axis at intervals

of 20 m or 30 m

b) Reservor

The soil shoud be collected in left hand and right hand side towards the fetch

area (windward side) at intervals of 30 m.The depth of these Boreholes (BH) and

Test Pits (TP) depends on the soil strata and the presence of impervious materials

(Clay) and hard rock.

c) Spillway section

The Test pit or boreholes should be conducted along the spillway Chanel to

determine the soil materials if it is eroded materials or it is a rock (soft or hard

rock) at the interval of 30 m.

d) Borrow area section

The borehole or test pit should be conducted on borrow area to determine

the suitable soil materials for dam construction and to quantify the amount of

materials to be used for dam construction.

1.4.3 Suitability of Soil Materials for Dam Construction

The soil materials suitable for earthen dam construction are of two types:

- Silty clay sand of medium plasticity and

- Silty clay sand of high plasticity

If the materials at the site are predominantly found to have a lot of silty clay sand of medium plasticity, the dam will be homogeneous which means the same character of soil materials will be used. This should contain between 20 to 30 percent clay with balance made up of Silt, sand and some gravel. If a Unified Soil Classification has to be carried out, the selected clays should be in order of presence of, GC, CS, CL, and CH. Normally, homogeneous dams are confined to relatively small heights with maximum of 6m.For dams in excess of 6metres, a zoned embankment is recommended. But if the site has plenty of silty sand clay of high plasticity, the dam will be zoned and both type of soil materials will be used whereby the high clay materials will form the inner part (core) while the medium will be the outer part (shell materials).The above statement depends on the availability of the materials at the selected site. The zoned embankment is more stable.

1.4.4 Determination of In-Situ Bearing Capacity of the Soil

(a) In-situ bearing capacity

The in-situ bearing capacity of the soil should be determined in order to know the

bearing capacity of the soil before implementation of the civil structure and can

be used for preliminary design of the structure.

There are several methods which are used to conduct in-situ bearing capacity of

the soils

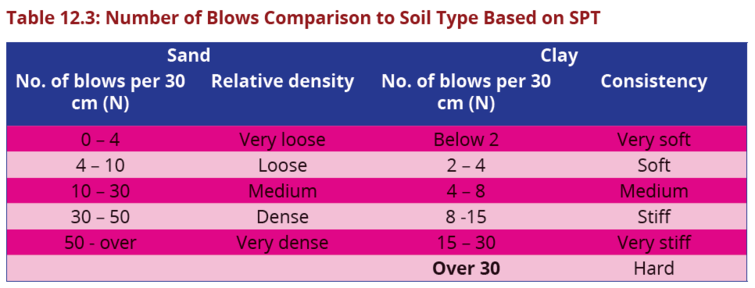

(i) Standard penetration test (SPT)

This method is done by drilling boreholes and conducting the SPT tests at the

interval of 1.5 m downwards. The number of blows is applied by using a freefalling

hammer of 63.5 kg at the height of 750 mm through the rod which is

mounted with the cone of 60º at the tip end.

By means of a drop hammer of 63.5 kg mass falling through a height of 750 mm at the rate of 30 blows per minute, the sampler is driven into the soil. This is as per IS -2131:1963 (Indian standards). The number of blows of hammer required to drive a depth of 150mm is counted. The main aim is to perform standard penetration in order to obtain the penetration resistance (N-value).The number or blows required for 300 mm penetration resistance of the soil. It is generally referred to as the ‘N’ value and is measured in blows/unit penetration. The Standard penetration test (SPT) is widely used to get the bearing capacity of the soil directly at a certain depth. The standard penetration test is an in-situ dynamic penetration test designed to provide information on the geotechnical engineering properties of soil.

The main purpose of the test is to provide an indication of the relative density of granular deposits, such as sands and gravels from which it is virtually impossible to obtain undisturbed samples. The operation entails the operator counting the number of hammer strikes it takes to drive the sample tube 6 inches at a time. Each test drives the sample tube up to 450mm deep. It is then extracted and if desired a sample of the soil is pulled from the tube. The borehole is drilled deeper and the test is repeated’

(ii) Dynamic cone penetration (DCP)

This method is the same as above but the dropping hammer is 10kg at a height of 1.m

Table No 12.3 shows indicators for penetration resistance of different types of soils based on the standard penetration tests in relation to the number of blows per 30 cm of penetration (based on Terzaghi and Peck).The table shows relative densities of soils corresponding to the number of blows.

(b) Laboratory Soil Test for Civil Engineering purposes

In order to determine the suitable classification of soil materials for dam

construction, the following laboratory tests should be conducted in a soil

laboratory.

(c) The Tests to be conducted for dam construction:

There are many tests which should be done before project implementation

which gives the soil character of the selected area. These are classified as soil

mechanical and chemical test.

(d) Indicator test or preliminary

In order to determine the soil classification for civil structures, one should know the type of soil and its strength where the structure will be built by conducting the following laboratory tests;

- Sieve analysis or particle size distribution of the soil materials by percentage. This will determine the percentage of Gravel, Sand, Silt and Clay.

- Atterberg limits this will determine the percentage of plasticity of the soil that is Liquid limit, Plastic limit and Plastic index.

- Bulk density this will determine the unit weight of the soil in g/cm3

- Natural moisture content (NMC) this will determine the percentage of water content of soil before using the materials.

- Linear shrinkage this will determine the expansion and shrinking of the soil material in percentage.

- Free swell of the soil this is expressed in percentage to determine the swelling of the soil when subjected to the water.

- Specific gravity of soil particles this used for calculations of voids in soil

- Permeability test this indicate the water percolation in soil particle which depends the particle size of the soil particles arrangement and compaction.

(e) Strength test; or Secondary test.

Shear test, this will determine the cohesion and angle of response of the soil for ultimate bearing calculations

Consolidation test, this will determine the coefficient of volume compression (Mv) and compression index (Cc) of the soil for settlement calculation in soil foundation design.

- Triaxial test ,this is more advanced than shear test, it is three force acting on soil sample during the test .This will determine the cohesion of the soil and an angle of friction for the drained and undrained soil.

- Proctor test. This will determine the maximum dry density and Optimum moisture content- The parameters will be used for determination of percentage of compaction during the dam, road and Airfield construction. The filling of layer thickness should be 300mm.before compaction.

(f) Chemical tests for dispersion of soil materials used for dam construction

The Total Exchangeable bases such as (Magnesium (Mg+), Sodium (Na+), Calcium (Ca+), and potassium (K+) is the one of the causes of soil dispersion. Generally, the causes of soil dispersion increases with the Sodium percentage. If Na+ of the Total Exchangeable bases is more than 15%, the soil will be dispersed.

Soil Texture may contribute to formation of dispersive soils if silt % is greater than 60%.In this case, the hydrometer or sedimentation test should be conducted to determine the percentage of silt and clay separately.

(g) The tests of soil chemical for concrete

The soil must be tested for Chemical concern concrete works such as content of Sulphate, pH value, Sodium chloride and impurities which lower the strength of concrete during hardening.

1.5 Occupational Health and Safety

In all water supply projects implemented by any funding sources the working environment at the sites will have to comply with the Occupational Health and Safety (OHS) Act (2003), OSH Policy (2010), OSH rules of 2015, 2017, 2018 and any subsequent amendments. These can be accessed on the MoW Website - http://www.maji.go.tz/.

REFERENCES

https://www.academia.edu/37842758/Determination_of_the_Flakiness_and_the_

Elongation_Index_for_the_Given_Aggregate_Samplehttp://www.raklab.com/index.

php/testing-services/chemicalhttp://www.concrete.org.uk/fingertipshttp://

www.concrete.org.uk/fingertips-nuggets.asp?cmd=display&id=910

https://civiconcepts.com/2019/01/los-angeles-abrasion-test-on-aggregate/

Previous Page: Chapter_Eleven:_Metering << >> Next Page: Chapter_Thirteen:_Role_of_Stakeholders_in_Design_of_Water_Supply_Projects